Through touch screen panel,it is easy to set or adjust working parameters.The language of it can be customized as needed.The data

can be stored in panel and be reused at next time,saving time on operation process.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.5

-

Place of Origin:

-

ZHUAMDIAN

-

Weight:

-

2000 KG

-

Keywords:

-

Linear servo quantitative filling machine

-

Material:

-

SUS304

-

Control:

-

PLC+ Touch Screen

-

Packing speed:

-

4000bph

-

Suitable bottle:

-

0.2-2L Plastic Bottle

-

After-Sales Service Provided::

-

Engineers Available To Service Machinery Overseas

-

Advantage:

-

Running Steady

-

Filling Volume:

-

200ml-2000ml

-

Certification:

-

CE TUV

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Glass, Other

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

0.5

-

Place of Origin:

-

ZHUAMDIAN

-

Weight:

-

2000 KG

-

Keywords:

-

Linear servo quantitative filling machine

-

Material:

-

SUS304

-

Control:

-

PLC+ Touch Screen

-

Packing speed:

-

4000bph

-

Suitable bottle:

-

0.2-2L Plastic Bottle

-

After-Sales Service Provided::

-

Engineers Available To Service Machinery Overseas

-

Advantage:

-

Running Steady

-

Filling Volume:

-

200ml-2000ml

-

Certification:

-

CE TUV

zhongyilong: A Trusted Name in filling packing Business

we provides the best filling packing euioment for business, home, and industry. 0ur business scope includes the preparation of laboratory purewater, the provision of household drinking water, small water plants/mineral water production busine and so on. We have always built relationships throughcuality and efhciency. Al of our products are made with the highest quality components to provide you with only the best filling packing equipment.Contact us for your pure water equipment solution!

Select us for your solution Tailor made, provide you complete turnkey solution

zhongyilong’s expertise in liquid packaging ensures the perfect combination of process design and product-line engineering. With the established process design system of various liquid packaging fields such as beverages, dairy products, liquors, condiments, and daily chemical products, we can provide customized turnkey solution for your project considering different packaging forms and specific factory layouts.

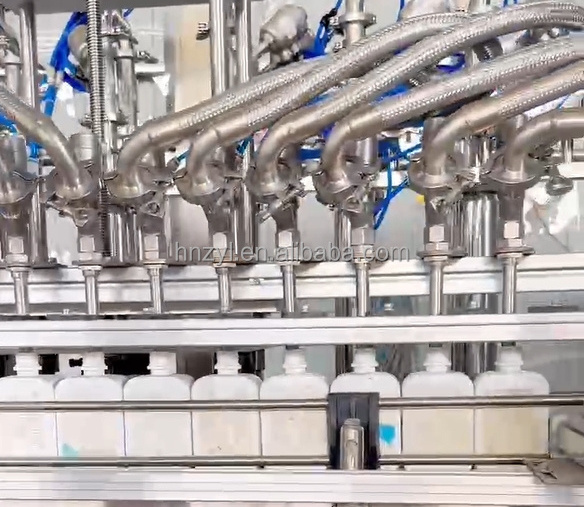

Automatic 4 /6/8/12 Heads Servo Piston Pump Juice Beverage oil Quantitative Cosmetic Bottle Liquid Filling Machine

Fully Automatic Servo Piston Pump Filling Soap Hand Washing Liquid Detergent Cosmetic Bottle Filling Packaging Machine

The series injection type gravity type dual-use filling machine is a high-tech product researched and developed by our company.It is suitable for products of various viscosities such as water injection, semi-fluid, ointment and shampoo etc. It is widely applied for filling of products in such industries as food, cosmetics, grease, daily chemical

industry,detergent, and chemical industry etc. By adopting straight line filling model, it can be used to fill solution of different types without the need of adding any spare parts.

This automatic filling machine is equipped with magnetic pump,which can ensure the filling accuracy.The filling speed of each nozzle can be controlled separately. It has compact design, beautiful appearance,wide application field, and it worked with imported parts, so that the the machine has a good performance.This machine is suitable for filling essential oil,eye drops,ink

Laundry detergent, hand sanitiser, disinfectant water, daily chemical liquid products

etc

Products Description

This automatic piston pump filling machine is equipped with feeding pump,this is more convenient for feeding filling material.Different filling range can be chosen and multiple filling nozzle can be customized according to operation need.

Automatic bottle filling machine can fill different viscosity liquid and paste,such as liquid soap and laundry detergent,liquid

fertilizer,honey filling line ,motor oil and so on.The machine can be customized 4 filling heads/ 6 filling heads/ 8 filling

heads/ 10 filling heads/ 12 filling heads ,16 filling heads, 18 filling heads etc, according to the filling capacity customers

needed.

This is the specification of the filling machine and some details of the front and back . it use 3-3.5mm thickness food grade

316L, international brand accessories , 99.9%high filling precision , it is a good choice for liquid filling ,gel filling and

paste filling.

|

Number of washing positions

|

Number of filling nozzles

|

Rated output (500ml)

|

Installed capacity (KW)

|

Dimensions (length × wide × High)mm

|

|

4

|

4

|

3000BPH

|

3

|

1900×1420×2000

|

|

6

|

6

|

4000BPH

|

3.5

|

2200×1600×2300

|

|

8

|

8

|

6000BPH

|

4

|

2450×1900×2300

|

|

10

|

10

|

10000BPH

|

4.8

|

2750×2180×2300

|

|

12

|

12

|

12000BPH

|

7.6

|

4000×2300×2300

|

|

16

|

16

|

15000BPH

|

8.3

|

4550×2650×2300

|

|

18

|

18

|

20000BPH

|

9.6

|

5450×3210×2300

|

Features

1. This production line adopts automation technology, imported PLC, imported inspection light eye, frequency converter and other

electrical appliances, pneumatic components. It has the characteristics of high efficiency, intelligence, wide adaptability and

good stability, and is well received by users;

2. This line uses automatic bottle feeding, 4-head servo magnetic drive pump filling machine, elevator automatic capping, servo

screw cap, wafer positioning round bottle labeling machine, and bottle collection to form a fully automated production line;

3. The filling machine uses food-specific hoses and does not contain plasticizers, which is suitable for medicine, food and other

industries;

4. The piston cylinder of the filling machine adopts grinding and wear-resistant metering cylinder, which can automatically

compensate the piston seal for long life;

5. The capping machine uses a manipulator to grasp the cap, press the cap, and control the capping torque through a servo motor to

achieve the capping effect; (Optional)

6. This type of capping machine has uniform force for capping, easy to adjust the force, and it is not easy to wear the cap;

(Optional)

7. The production line has stable operation, low noise, convenient maintenance, and fully meets GMP certification requirements,

and is widely used in food, cosmetics and other industries;

8. The whole machine is made of corrosion-resistant stainless steel, which is easy to clean and disinfect, and meets the national

regulations and requirements on food machinery and food hygiene;

9. Imported PLC and 7-inch touch screen man-machine interface, production parameterized control, simple operation;

10. This kind of production line is relatively advanced, and can be improved according to the different requirements of customers,

and can be made into equipment that fully meets the needs of customers, which is safe and hygienic.

11. Suitable for of different capacity, better accuracy. 12. Can be connected with capping machine, labeling machine, etc..

13. Easy to clean and simple to operate.

1. This production line adopts automation technology, imported PLC, imported inspection light eye, frequency converter and other

electrical appliances, pneumatic components. It has the characteristics of high efficiency, intelligence, wide adaptability and

good stability, and is well received by users;

2. This line uses automatic bottle feeding, 4-head servo magnetic drive pump filling machine, elevator automatic capping, servo

screw cap, wafer positioning round bottle labeling machine, and bottle collection to form a fully automated production line;

3. The filling machine uses food-specific hoses and does not contain plasticizers, which is suitable for medicine, food and other

industries;

4. The piston cylinder of the filling machine adopts grinding and wear-resistant metering cylinder, which can automatically

compensate the piston seal for long life;

5. The capping machine uses a manipulator to grasp the cap, press the cap, and control the capping torque through a servo motor to

achieve the capping effect; (Optional)

6. This type of capping machine has uniform force for capping, easy to adjust the force, and it is not easy to wear the cap;

(Optional)

7. The production line has stable operation, low noise, convenient maintenance, and fully meets GMP certification requirements,

and is widely used in food, cosmetics and other industries;

8. The whole machine is made of corrosion-resistant stainless steel, which is easy to clean and disinfect, and meets the national

regulations and requirements on food machinery and food hygiene;

9. Imported PLC and 7-inch touch screen man-machine interface, production parameterized control, simple operation;

10. This kind of production line is relatively advanced, and can be improved according to the different requirements of customers,

and can be made into equipment that fully meets the needs of customers, which is safe and hygienic.

11. Suitable for of different capacity, better accuracy. 12. Can be connected with capping machine, labeling machine, etc..

13. Easy to clean and simple to operate.

Product details

PLC Part.

Filling Part.

Driven by servo motor,it can run stably and fill paste or liquid accurately.The filling speed can be set in two stages, enabling

it to fill foamy liquid like soybean milk.Quantity of filling heads can be customized as needed.

it to fill foamy liquid like soybean milk.Quantity of filling heads can be customized as needed.

With large-capacity hopper,it is easier to pour materials,improving working efficiency.It can be equipped with mixer and heater,which can ensure smooth filling.

Please contact us if you need.

With chain conveyor belt,it has large loading capacity,which can transport products stably.The conveying speed and width of conveyor belt can be adjusted as needed.

The conveying is smooth, there is no relative movement between the material and the conveyor belt, which can avoid the damage to the conveying material, the structure is simple, easy to maintain, the energy consumption is small, the use cost is low.

Main configuration:

1. Frame, foot and guardrail materials: aluminum profile, 304 stainless steel

2. Pneumatic components: Taiwan brand AIRTAC

3. Program controller: aelta

4. Man machine interface: aelta 7-inch color touch screen

5. power supply: MEAN WELL

6. Relay and air switch: chnt

7. Motor frequency converter: Aelta

8. Materials of exposed parts: aluminum profile, stainless steel, anodized aluminum alloy, electroplated 45

steel and plastic parts

2. Pneumatic components: Taiwan brand AIRTAC

3. Program controller: aelta

4. Man machine interface: aelta 7-inch color touch screen

5. power supply: MEAN WELL

6. Relay and air switch: chnt

7. Motor frequency converter: Aelta

8. Materials of exposed parts: aluminum profile, stainless steel, anodized aluminum alloy, electroplated 45

steel and plastic parts

application

Use objects: all kinds of liquor, beverages, mineral water, oral liquid, purified water, mineral water, honey, liquid condiments and other liquid materials.

Industry: food and beverage, daily chemical, chemical, etc

OEM/ODM

Supply bottle&label design and factory layout for free!

Why Choose Us

Related products

About us

FAQ

Q1: Where is your factory? How can I visit your factory?

A: Our factory is located in Henan Province. If you have a travel plan, we warmly welcome you to visit our factory

Q2: Can you send me a video to show me how the machine works?

A: Of course, we made videos of each machine

Q3: How do I know your machine is designed for my product?

A: You can send us your product samples, and we will test them on the machine

Q4: How do I pay for my order?

Answer: Usually we accept L/C, D/A, D/P, T/T, Western Union, MoneyGram and cash payment

Q5: Do you have a Ce certificate?

A: For each model of machine, it has CE certification

Hot Searches