- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

29kw

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KAIYUANJINGKE

-

Weight (KG):

-

4500 KG

-

Power (kW):

-

29kw

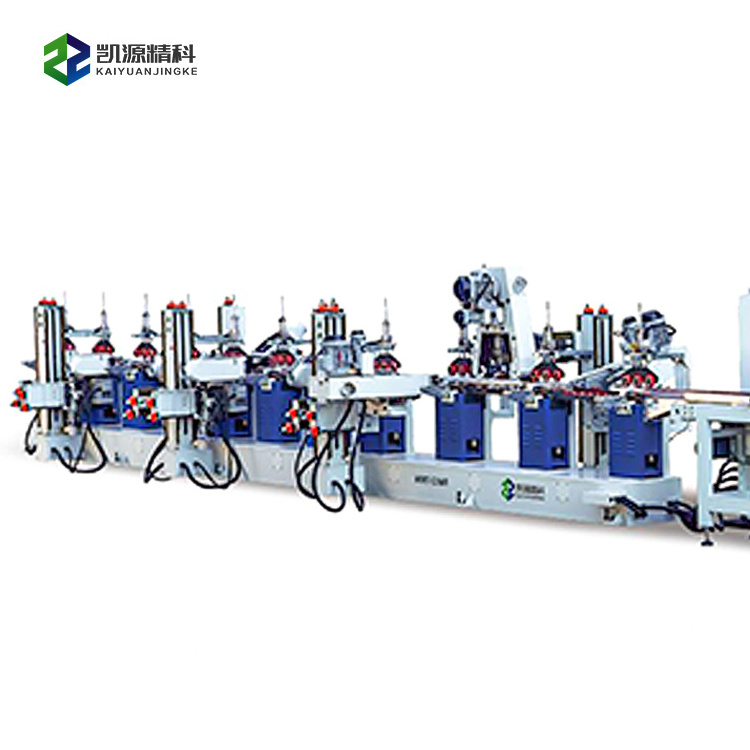

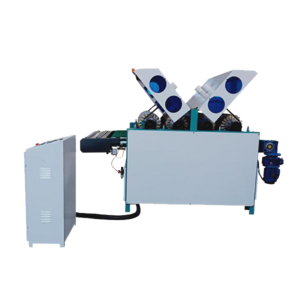

Vacuum spraying advantages : Reduce the loss, paint uilization close to 100%.

Save labor : with 40m/min zero emissions of harmful substances, to meet.

The stringent environmental requirements, to protect the health of operators.

Unique spray device desigh, the mechanical opening in tie case of the profile,

the use of Venturi effect to obtain a vacuum environment of the paint atomization,

sprayingthe workpiece.

The workpiece can be sprayed once around the shape; also choose to spray the

designated spray surface.

The workpiece does not touch the edge of the moldopening during spraying and

draws the painted surface.

Spray coating process does not appear to leak and excessive spraying, coating to

maintain a high degree of consistency.

Unique coating operation andrecovery device to ensure that paint is fully utilized ,

there is no waste , and to prevent paint from flying to the outside world to protect

the operator and the environment.

Unique systematic design, easy access to different thickness of the coating.

A variety of coatings can be sprayed, such as waterborne coatings, UV coatings

and waterborne UV coatings.

Unique internal spraying mechanism, cleanng and replacement of paint quickly

and easily.

Intelligent automation desigh, raduce the difficulty of mechanical operation.

|

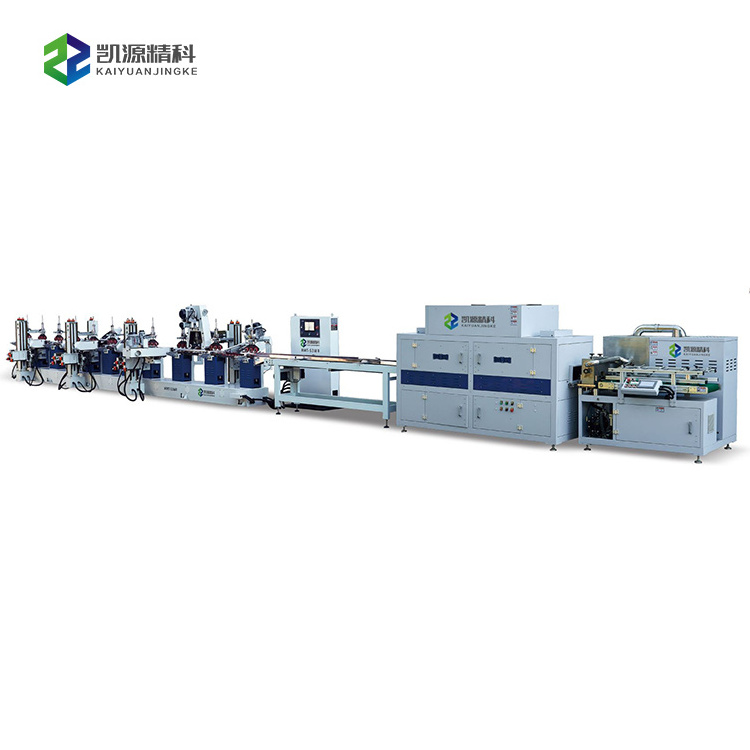

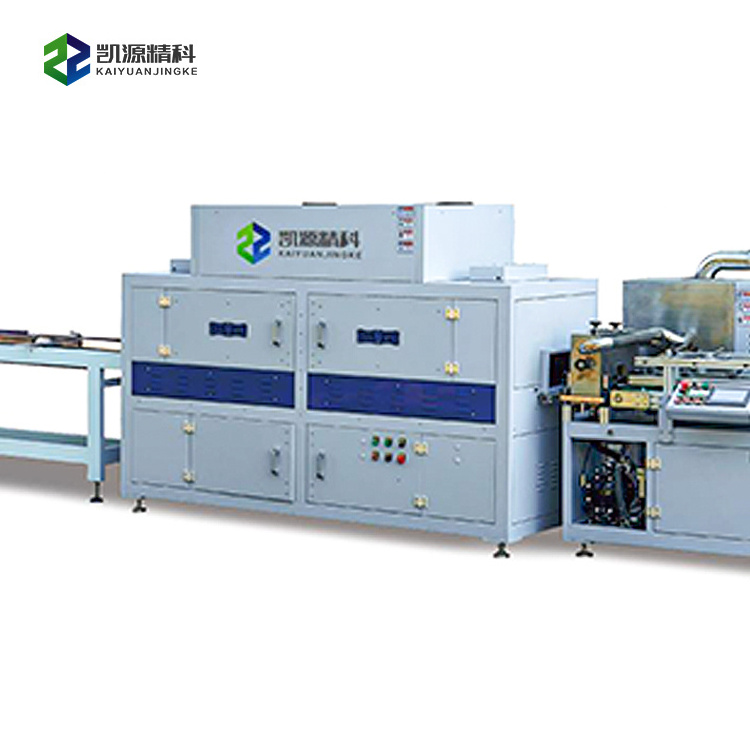

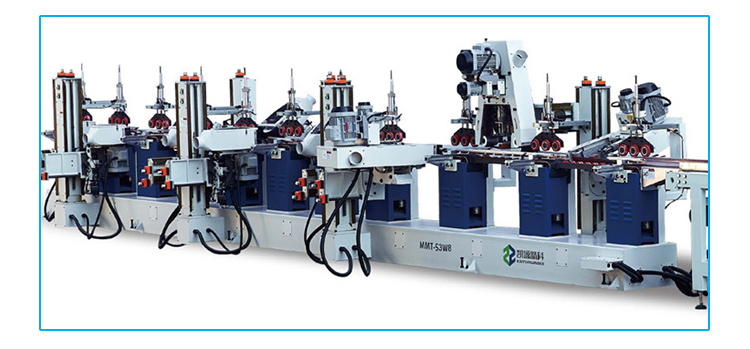

Machine model

|

MMT-S3W8

|

|

Maximum width of workpiece

|

220×400mm

|

|

Minimum height of workpiece

|

100mm

|

|

Minimum length of workpiece

|

400mm

|

|

Table height

|

850mm

|

|

Feeding speed

|

0~30m/min

|

|

Working power supply

|

380V 50Hz

|

|

Control mode

|

Frequency conversion control

|

|

Total power

|

29kw

|

|

Dimension

|

8820×1700×1500mm

|

|

Weight

|

4500kg

|

ABOUT US

FOSHAN KAIYUAN JINGKE MACHINERY CO., LTD. is located in Shunde Lunjiao, the leading city of woodworking machinery manufacturing in China. It is committed to provide customers with the

solutions

of

blank, painting

and

sanding

for the surface of various workpieces such as

doors

,

windows

,

picture frames

,

cabinets

,

closets, bathrooms

,

wood lines

, etc.

In order to help customers better to improve product quality, increase productivity, and enhance their competitiveness, KAIYUAN JINGKE Machinery has established a comprehensive and effective sales and service network in the country, and committed to provide thorough

pre-sale

,

selling

and

after-sales service

to the new and old customers. The company focus on the implementation of

performance management

and

user feedback

, and improve itself in terms of

quality service

and so on, and do everything possible to

meet customer needs

to achieve win-win situation.

PROFESSIONAL TEAM

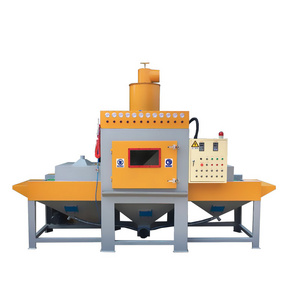

It has many senior technical personnel, serving the R & D, production and after-sales departments. Based on years of equipment manufacturing experience, KAIYUAN JINGKE machinery actively absorbs and introduces advanced technology and management mode at home and abroad, and produces a variety of high-quality products with advanced equipment and mature technology: Production line, Wide brush sander, Linear sander, Edge sander, UV Edge painting, Sand blasting machine, Curve sander, Primer sander and Automatic auxiliary equipment, It has been widely used in the industry.

Q1.About us,the relation between factory,manufacture or trader?

A1. Hetaijin group is a professional production of coldrolled stainless steel conglomerate , with professional production of stainless steel experience and our own factory nearly 12 years,where has more than 1,000 professional and technical workers. we are the foreign trade department of Hetaijin. All our goods are dispatched directly from Hetaijin mill.

Q2.What are Hetaijin’s main products?

A2.Hetaijin’s main products include 201/304 stainless steel coil and sheets,all different styles of etched and embossed,surface finished will be customized.

Q3.How can you ensure the quality of your product?

A3.All products have to go through three checks in the whole manufacturing process,it includes production,cutting sheets and the packing.

Q4.What is your delivery time and the supply ability?

A4.The delivery time normally within 15~20working days,we can supply about 15,000tons every month.

Q5.What kind of equipment in your factory?

A5.Our factory have advanced five-eighth roller rolling,cold rolling production equipment on the roll,advanced processing and testing equipment,which makes our product better quality with efficiency.

Q6.About the complaint,quality problem,etc aftersales service,how do you handle it?

A6.We will have certain colleague to follow our order accordingly for each order with professional after-sales service. If any claim happen, we will take our responsibility and compensate as per contract. For better serve our client, we'll keep tracing feedback of our products from clients and that's what make us different from other suppliers. We're customer care enterprise.

Q7.As the first customer,how do we trust you?

A7.On the top of page,you can see a line of credit with $228,000. It provides our company with higher degrees of credibility in the alibaba.We can guarantee the safety of your order.

Hot Searches