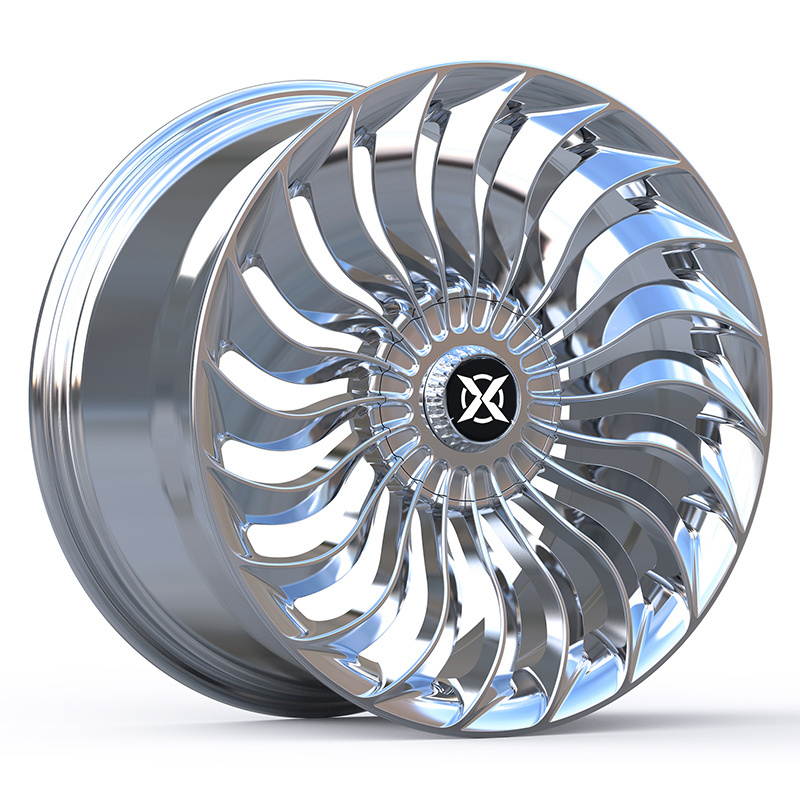

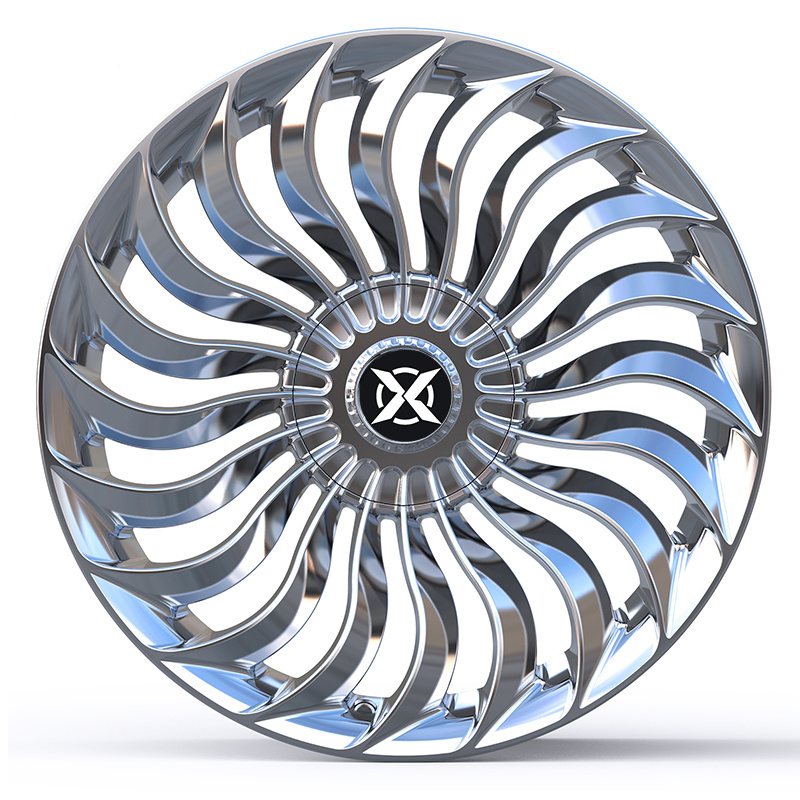

- Product Details

- {{item.text}}

Quick Details

-

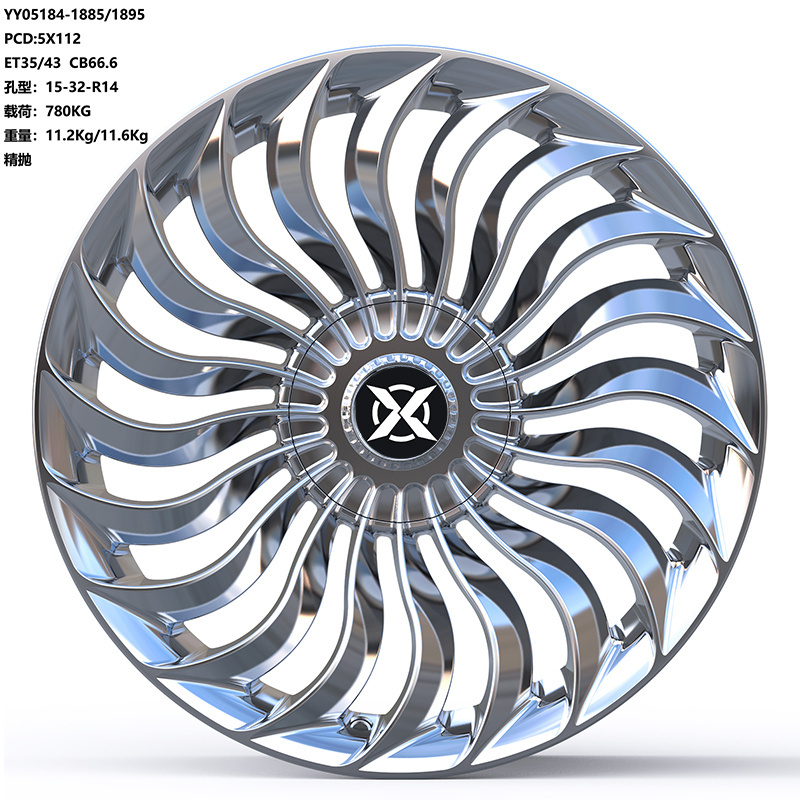

Brand Name:

-

XieHe, XieHe

-

Warranty:

-

36 months

-

Model Number:

-

XH-M005

-

Product Name:

-

mag wheels

-

Application:

-

Vehicle modified

-

Technology:

-

12000T High Pressure

-

Manufacturing Process:

-

CNC

-

Hole:

-

5 Holes/customized

-

Logo:

-

Custom Logo Accepted

-

Certification:

-

ISO9001-2000,TS16949,VIA

-

Delivery time:

-

10-20 days

Quick Details

-

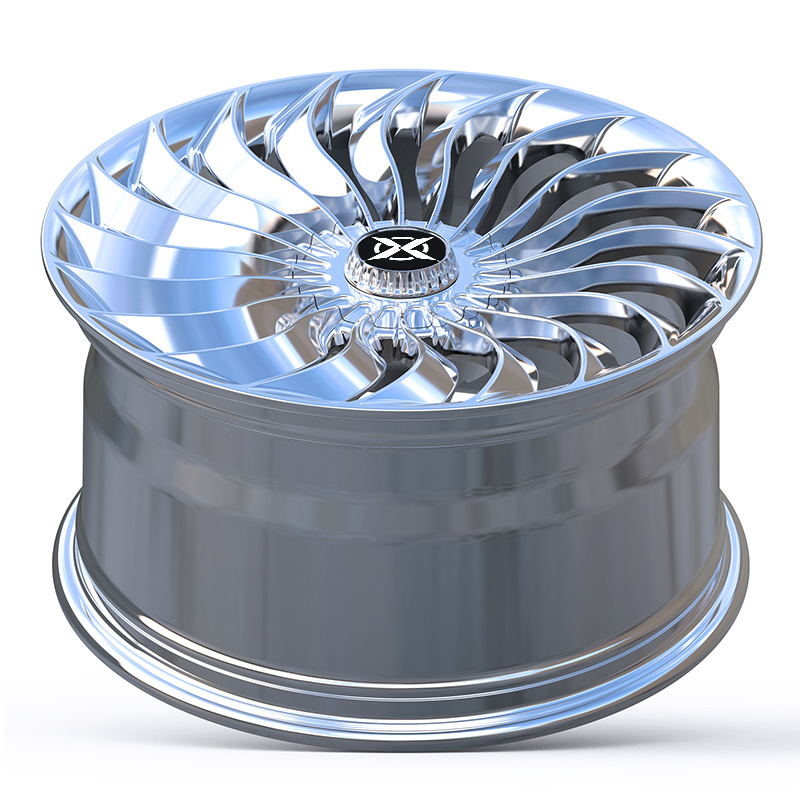

Finishing:

-

silver

-

Width:

-

5/5.5/7/7.5/8/8.5/9/9.5/10/10.5/11/11.5/12 Inch

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XieHe, XieHe

-

Warranty:

-

36 months

-

Model Number:

-

XH-M005

-

Product Name:

-

mag wheels

-

Application:

-

Vehicle modified

-

Technology:

-

12000T High Pressure

-

Manufacturing Process:

-

CNC

-

Hole:

-

5 Holes/customized

-

Logo:

-

Custom Logo Accepted

-

Certification:

-

ISO9001-2000,TS16949,VIA

-

Delivery time:

-

10-20 days

|

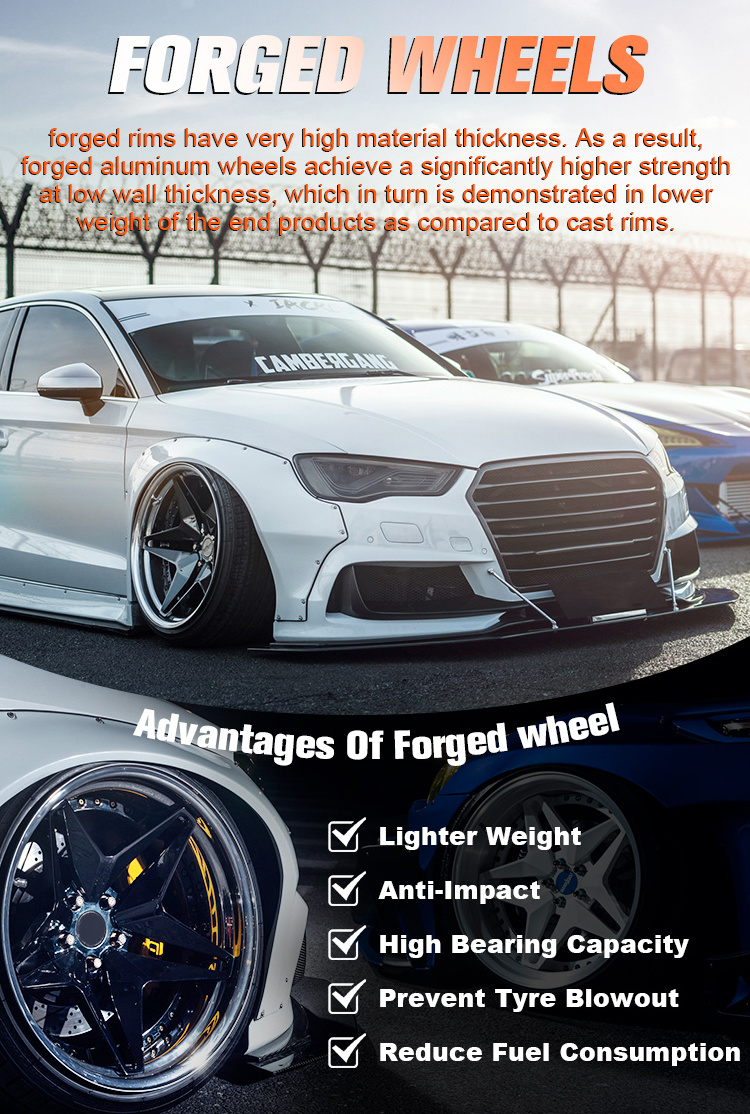

Advantages Of Forged Wheels

|

|

|

||

|

Forged wheels

|

VS

|

Cast wheels

|

||

|

Forged wheels are based on vehicle weight and Safety performance level for wheel structure design higher security

|

Security

|

Cast wheels are mass production driving safety low grade

|

||

|

Forged wheels except for pitch/offset/center hole/ general data such as J value exclusive design for special car .

Also according to brake calipers size to adjust the spoke arc

|

Suitability

|

Cast wheels are not private car does not meet data does not match

|

||

|

Aviation aluminum T6061 high manufacturing cost high density impact resistance strong ability

|

Material

|

Ordinary aluminum melts,low manufacturing cost, density difference, easy to deform and crack

|

||

|

Through the 10,000-ton forging process, the molecular structure of the wheel is tighter,the rigidity is stronger,and the weight is lighter

|

Lightweight

|

Cast wheels are liquid die casting ,craftsmanship relatively simple

|

||

Facts&Figures:

1. Premium design rims

2. Extremely Sophisticated manufactruing process

3. Top quality base material 6061-T6(used in aviation industry)

4. Weight reduction approx. 30% due to higher material density.

5. Thinner spokes achieved by recessed spokes

6. Stronger gloss effect due to a silicon amount of just 0.8%

7. Highest quality ceramic polish with double clearcoat.

Facts&Figures:

1. Premium design rims

2. Extremely Sophisticated manufactruing process

3. Top quality base material 6061-T6(used in aviation industry)

4. Weight reduction approx. 30% due to higher material density.

5. Thinner spokes achieved by recessed spokes

6. Stronger gloss effect due to a silicon amount of just 0.8%

7. Highest quality ceramic polish with double clearcoat.

Advantages of forged alloy wheels:

As is clearly seen from the graph, forged rims have very high material thickness. As a result, forged aluminum wheels achieve a significantly higher strength at low wall thickness, which in turn is demonstrated in lower weight of the end products as compared to cast rims.

In addition to this, the surface condition is of higher quality than that of a "cast rim" as hardly any air of

material inclusions occur.

material inclusions occur.

FAQ

1) When can I get the price?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us.

2) How can I get a sample to check your quality?

We'll provide sample after you pay sample charge to us. The account is up to your samples, usually it is USD 100-200 per style, but if there are many craft, and it is complex, the sample fee will be higher.

3) How long can I expect to get the sample?

At usual 13-20 days after receive the sample charge & design file.

4) What about the lead time for mass production?

It depends on the order quantity and the season you place the order,Mostly the production time is 15-30 days.

1) When can I get the price?

Hot Searches