- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ODMT

-

Model Number:

-

MAQ-400/40BA-C

-

Product name:

-

valve test machine

-

Function:

-

testing safety valve

-

Keyword:

-

Safety valve calibration bench

-

Certificate:

-

CE Certificate

-

Material:

-

stailess steel

-

Color:

-

Customized Color

-

Dimension:

-

customized

-

Weight:

-

560kg

-

Temperature range:

-

Room Temperature

-

Standard:

-

BS.EN.ASTM

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

Hydraulic

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ODMT

-

Model Number:

-

MAQ-400/40BA-C

-

Product name:

-

valve test machine

-

Function:

-

testing safety valve

-

Keyword:

-

Safety valve calibration bench

-

Certificate:

-

CE Certificate

-

Material:

-

stailess steel

-

Color:

-

Customized Color

-

Dimension:

-

customized

-

Weight:

-

560kg

-

Temperature range:

-

Room Temperature

-

Standard:

-

BS.EN.ASTM

Product Description

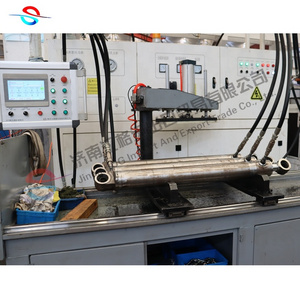

The new safety valve calibration table developed and manufactured by our company is suitable for performance testing of setting pressure, return pressure and sealing of direct load type and pilot type safety valve.Related standards:TSGZF001-2006 safety valve safety technical inspection regulations,

GB-T12242-2005 pressure release device performance test specification, GB-T12241-2005 safety valve general requirements, GB-T12243-2005 spring direct load safety valve, in line with safety valve performance test National standard

Specification

|

Machine Name

|

Computer Control Safety Valve Test Bench

|

|

Model

|

MAQ-400/40BA-C

|

|

Tested object

|

Safety valve

|

|

Features

|

Safety valve take-off pressure seal test

|

|

Test medium

|

Water and Air

|

|

Maximum test pressure

|

Gas:300 bar,/water :400bar

|

|

Maximum proof path

|

400mm/DN15-DN400

|

|

Calibration accuracy

|

±0.4%

|

|

Medium temperature

|

Room temperature +10-80℃

|

|

Ambient temperature

|

Room temperature

|

|

Simultaneous test pieces

|

1 piece

|

|

Wooden Cases

|

Export standard fumigation wooden cases

|

Machine Features

1.Pneumatic clamping and air-driven hydraulic clamping device are used, the clamping force is adjustable, and a pressure gauge is displayed to show the corresponding clamping force. A comparison table of pressure and clamping force is provided to facilitate the operator to verify the pressure and communication according to the safety valve. Select the proper clamping force.

2.Gas test: Use nitrogen in a nitrogen cylinder as the test pressure source, pressurized by a pneumatic booster pump, and used for testing. Equipped with a gas booster pump, the driving air source is 2-8bar.

3.Liquid test: Use water as the test medium, pressurized by the pneumatic liquid booster pump, and used for the test test. Equipped with an air-driven liquid booster pump,the booster medium is water, the driving air source is 2-8bar,.

4.All valves, fittings and joints are made of stainless steel.

5.In addition to the manual control of the check valve, the test process is computer operation, automatic clamping, automatic data recording, and printing of relevant data and pressure-time curve diagrams of the test process.

6. One sets of test and check bases, including 2 clamp bases, for DN10-DN400 test use.

7. The computer adopts industrial computer, which has stable performance, shock resistance and firmness. During the verification operation, the appearance inspection status, the reason for the failure, and the maintenance status of the inspected safety valve can be selected, and it can be automatically imported into the inspection report of the verification task and automatically saved.

8. During the calibration process, the setting pressure can be automatically measured and recorded, and the three qualified setting pressure values and average values measured can be automatically imported into the verification report of the inspection task, with a pressure-time curve attached.

9. Equipped with multiple test fixtures to meet the test requirements of the safety valve of the checkered series.

The Clamping Table Parameters

|

Clamping plate

specifications

|

Clamped safety valve caliber

|

Bore of cylinder or oil cylinder

|

Clamping force

(air pressure=6bar) |

|

Medium clamping plate

|

Φ15-Φ200

|

Oil cylinder bore: 80mm

|

1.8T-13T

|

|

Large clamping plate

|

Φ50-Φ400

|

Oil cylinder bore: 125mm

|

9.8T-30T

|

A-Medium clamping plate Power source cylinder Calibration caliber:DN25-DN200 DN-mm PN-MPa

|

|

≤32

|

40

|

50

|

65

|

80

|

100

|

150

|

200

|

|

100KN

|

32.0

|

32.0

|

32.0

|

25.0

|

20.0

|

12.0

|

5.5

|

3.0

|

|

80KN

|

32.0

|

32.0

|

32.0

|

20.0

|

15.0

|

10.0

|

4.0

|

2.5

|

|

50KN

|

32.0

|

32.0

|

20.0

|

15.0

|

10.0

|

6.0

|

2.7

|

1.5

|

|

35KN

|

32.0

|

25.0

|

15.0

|

10.0

|

5.0

|

4.0

|

1.8

|

0.8

|

Details Images

Test Bench Structure

|

The main components

|

Detailed composition

|

|

Clamping system

|

Hydraulic tightening: consists of reversing valve, oil cylinder, pneumatic hydraulic system, check seat and movable clamp feet

./Start the clamping device after the pin is in place, and reset the clamping device after the verification is completed |

|

Test cabinet

|

The main cabinet is made of Q235 and sprayed

|

|

Test system

|

It is composed of high-pressure valve, high-precision pressure gauge, pressure reducing valve, booster system, etc. Equipped with

precision pressure and pressure sensors ./The pneumatic dual body and solenoid valve are made by Airtac from Taiwan, the pressure sensor is made by IFM in Germany, and the booster pump is made by ODMT. The sealing parts of the booster pump are all imported from the United Kingdom. , Micro lift, metric, inch, threaded and domestic and imported safety valves |

|

Measuring system

|

Using the most advanced programming software and data acquisition system, Lenovo business computer./Computer real-time display of

the test process, LABBIEW programming software, NI acquisition card |

|

Control

|

Computer control

|

|

Related accessories

|

Center pad or inch diameter outer joint: 1 sets are specified by the customer.

“O” type seal: There are 30 specifications in total. |

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

Q1

: What's your main products of your company?

A1 : We specialized in all kinds of machines ,such as engine stand Hydraulic press riveting machine test bench brake riveting machine and so on .

Q2 : Where is our factory located? How can I visit there?

A2 : Add: Opposite to Quanfu Village Arch, Taohuayuan Road, Ping'an Street, Changqing District, Jinan, Shandong Province

Q4 : What's the Payment Terms ?

A4 : T/T ,50% initial payment when order ,50% balance payment before shipment ;Irrevocable LC at sight .

A1 : We specialized in all kinds of machines ,such as engine stand Hydraulic press riveting machine test bench brake riveting machine and so on .

Q2 : Where is our factory located? How can I visit there?

A2 : Add: Opposite to Quanfu Village Arch, Taohuayuan Road, Ping'an Street, Changqing District, Jinan, Shandong Province

Q3

: What is your trade terms?

A3 : FOB, CFR and CIF all acceptable.

A3 : FOB, CFR and CIF all acceptable.

Q4 : What's the Payment Terms ?

A4 : T/T ,50% initial payment when order ,50% balance payment before shipment ;Irrevocable LC at sight .

Q5

: What's the MOQ?

A5 : 1 set .(Only some low cost machines will be more than 1 set )

A5 : 1 set .(Only some low cost machines will be more than 1 set )

Hot Searches