- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

OEM/ODM

-

Product Material:

-

PC, PC+ABS,ABS, PP, PVC,POM, TPE, PEEK, TPU etc

-

Product:

-

Injection Molded Product

-

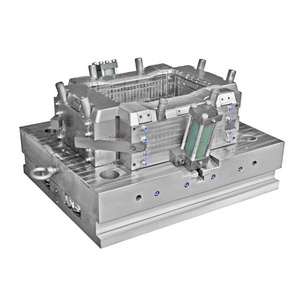

Mould Steel:

-

P20/NAK80/S136/H13/718H...

-

Mould Lifetime:

-

50k-1000k shots

-

Surface Treatment:

-

Texture/Sand/MT/YS/SPI

-

High Precision:

-

+/-0.01mm

-

Runner:

-

Hot runner and cold runner

-

Cavity:

-

Single or multi Cavity

-

Certification:

-

ISO9001, ISO14001, IATF16949

-

Color :

-

Pantone/RAL color code/Actual sample color

-

Mould base:

-

LKM HASCO

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong China

-

Brand Name:

-

Rilong

-

Model Number:

-

OEM/ODM

-

Product Material:

-

PC, PC+ABS,ABS, PP, PVC,POM, TPE, PEEK, TPU etc

-

Product:

-

Injection Molded Product

-

Mould Steel:

-

P20/NAK80/S136/H13/718H...

-

Mould Lifetime:

-

50k-1000k shots

-

Surface Treatment:

-

Texture/Sand/MT/YS/SPI

-

High Precision:

-

+/-0.01mm

-

Runner:

-

Hot runner and cold runner

-

Cavity:

-

Single or multi Cavity

-

Certification:

-

ISO9001, ISO14001, IATF16949

-

Color :

-

Pantone/RAL color code/Actual sample color

-

Mould base:

-

LKM HASCO

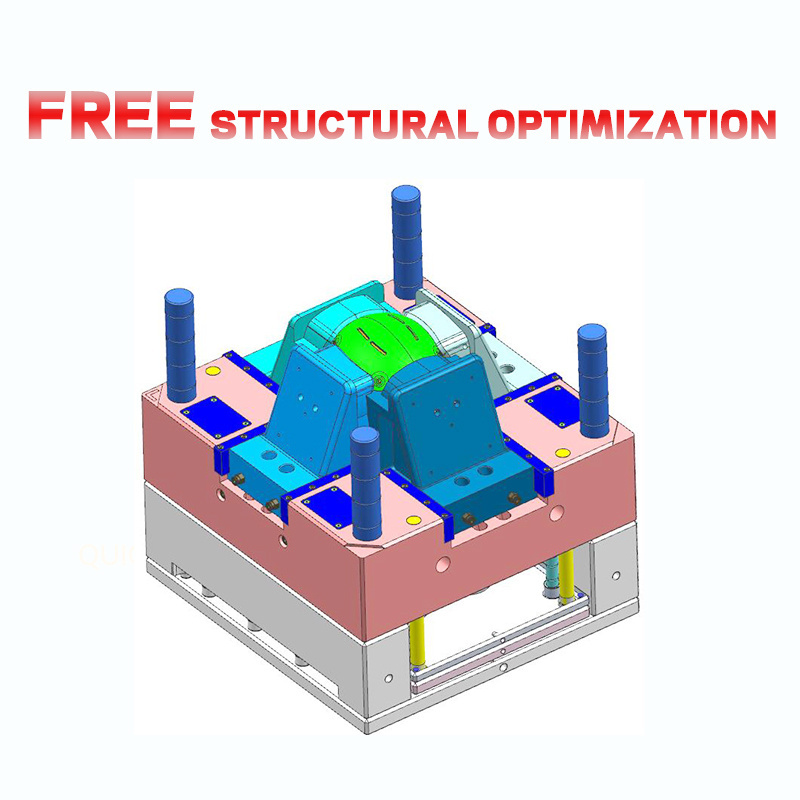

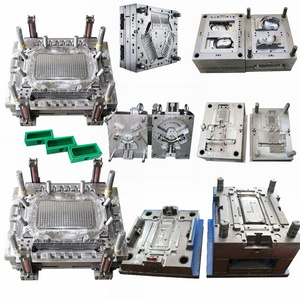

Our Advantages

|

✔️

Customized Mold

and products from your designs, with a quote in

24-48

hours.

✔️

30+

years experienced Mold&Moulding production

✔️Free

drawing analysis for optimization of product structure

✔️

Free

sampling

✔️

Comprehensive

services from Mold making - Injection/Rubber Molding - Silk-screen Printing - Electroplating etc - Assembly

We can provide our customers “one-stop service” solution from initial design to final assembled products with high quality, professional& financial best choices, on-time delivery, and excellent communications.

|

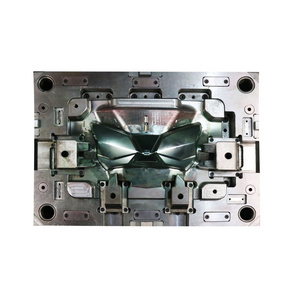

Product Description

|

Core Advantage

|

30+ years of experience on mold designing, CNC machining and compression&injection molding

|

|

Product Material

|

ABS, PC, PA6, PA66, PC+ABS, POM, PA6+10GF, Nylon, PE, PVC, PE, PVC, TPE, TPU, TPV, PET, PEI, LCP, PS, POM, ASA, HDPE, PEEK, PPS,

PPA, PBT, PMMA, PPSU, PSU, etc.

|

|

Product Finishing

|

Silkscreen, Hand oil coating, Laser etching, Spraying, Glossy coating, Matte Coating, UV Painting, Pad printing, Chrome Plating,

Nickle Plating, Non-conductive, Vacuum Metallization, EMV coating and etc.

|

|

Mold Standard

|

DME, HASCO,China domestic

|

|

Runner System

|

Hot runner and cold runner, YUDO hot runner

|

|

Mold Lifecycle

|

50k-1000k shots

|

|

Mould Finishing

|

Normal Polishing (SPI B1-B3), High Polishing (SPI A1-A3), VDI Texturing, YS1281 Texturing, EDM, Sandblasting Grinding

|

|

Inquiry Information

|

2D:dwg,dxf,edrw

3D:step,lgs,X-T,Prt,Sldprt

Physical Samples or the size of the multi-angle pictures

|

|

Advanced Tool Equipments

|

◆ 8 Advanced CNC machines: Charmilles, Seiki, MITSUBISHI ◆ 4 Advanced EDM : CHARMILLES, SODICK

◆ 2 Advanced WEDM: CHARMILLES,SODICK

|

|

Inspection Standard

|

FAI (First Article Inspection), Dimension Report,Outgoing products inspection report

|

|

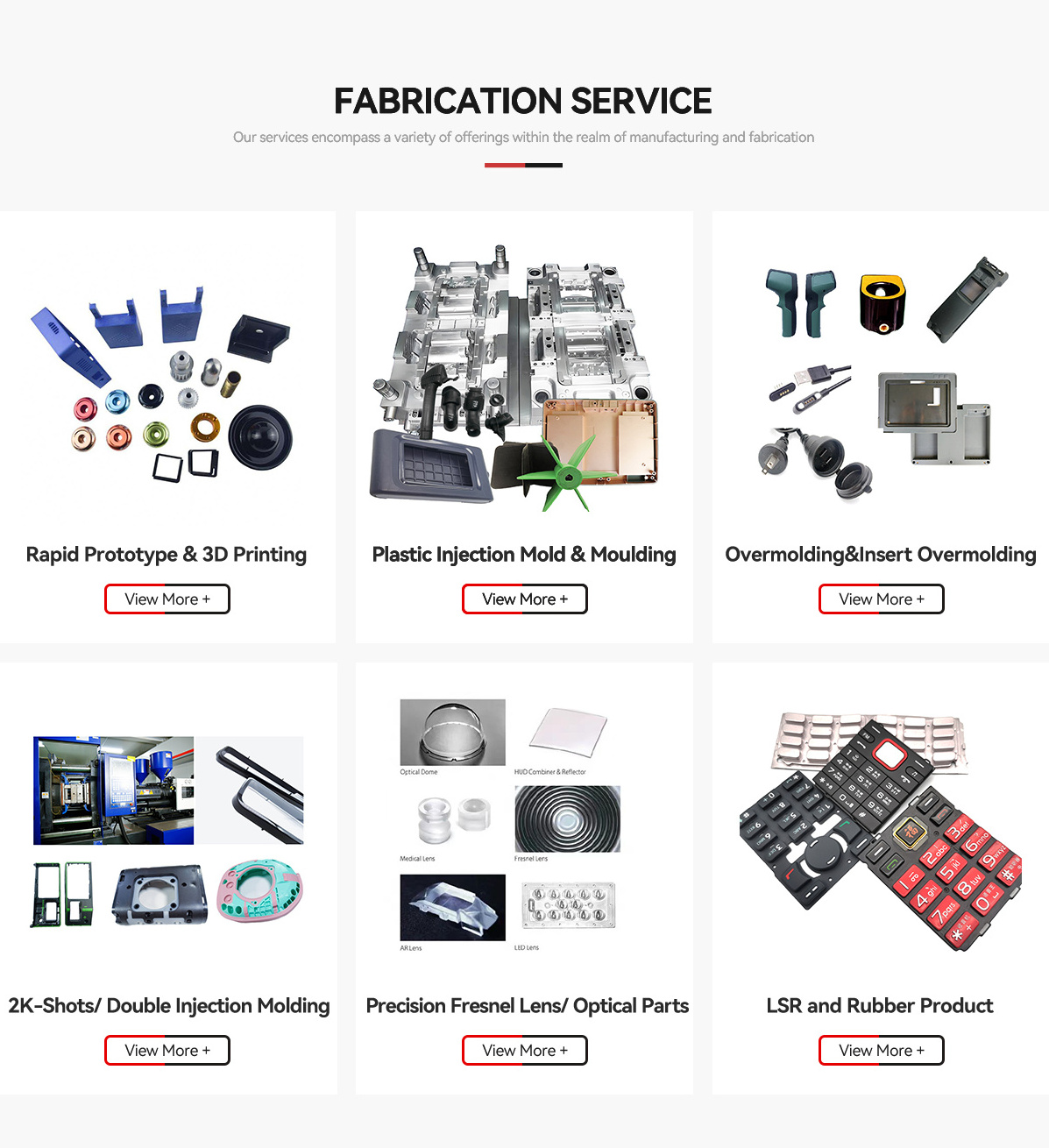

Fabrication Service

Specializing

in One-Stop Solution for R&D, Manufacturing and Assembly of Silicone rubber, Plastic molds and products for Precision Electronic, Medical, Security, Auto, Telecommunication and other industries parts.

✨Plastic Injection Molding

✨Twin-Shot Injection Molding

✨Multi-Color Injection Molding

✨Over-molding, Insert Molding

✨Liquid Silicone Rubber Injection Molding

✨Solid Silicone Injection Molding

✨Compression Molding

✨Custom CNC Machined AL/ SS/Copper/Brass/Plastic Prototypes

✨Mold Design and Manufacturing, Export Molds/Hasco/ DME

✨Painting, Pad/Silk Printing, Laser Etching and other Surface Treatment Processes

✨Ultrasonic Welding, Heat stamping, Glue dispenser, Assembly, Packaging

|

|

Providing

advice from the mold manufacturing perspective to ensure that the CNC/3D-printed prototypes align with the requirements of the final production stage. This includes considerations for special materials and design factors required for mold manufacturing.

Assisting

you in streamlining the entire manufacturing process, ensuring a smooth transition from 3D printing to mold manufacturing, enhancing efficiency, and reducing costs.

Possessing

a complete production chain, including mold design and manufacturing, injection molding, printing, laser engraving, ultrasonic welding, automated dispensing, nut hot melting, and assembly lines, thus establishing a centralized and scaled production base.

|

Production Line

|

In-house

CNC machining workshop, tooling building workshop, plastic injection molding and rubber molding workshop, secondary process workshop and OEM assembly.

All of

material meet with UL, Reach, Rohs certification and world-wide to meet the demand that customer multiple functional requirements.

|

Product packaging

|

Tailoring

the optimal packing method post-completion of the goods;

Crafting

bespoke package solutions, including blister packing, art package packing, cotton bag packing...

|

|

Creating

more than 10000 plastic/rubber molds

Exported

to the US, Europe Japan, etc.

500+

Cooperated Companies

Professional, Reliable, and Trustworthy

|

Work Chart

Hot Searches