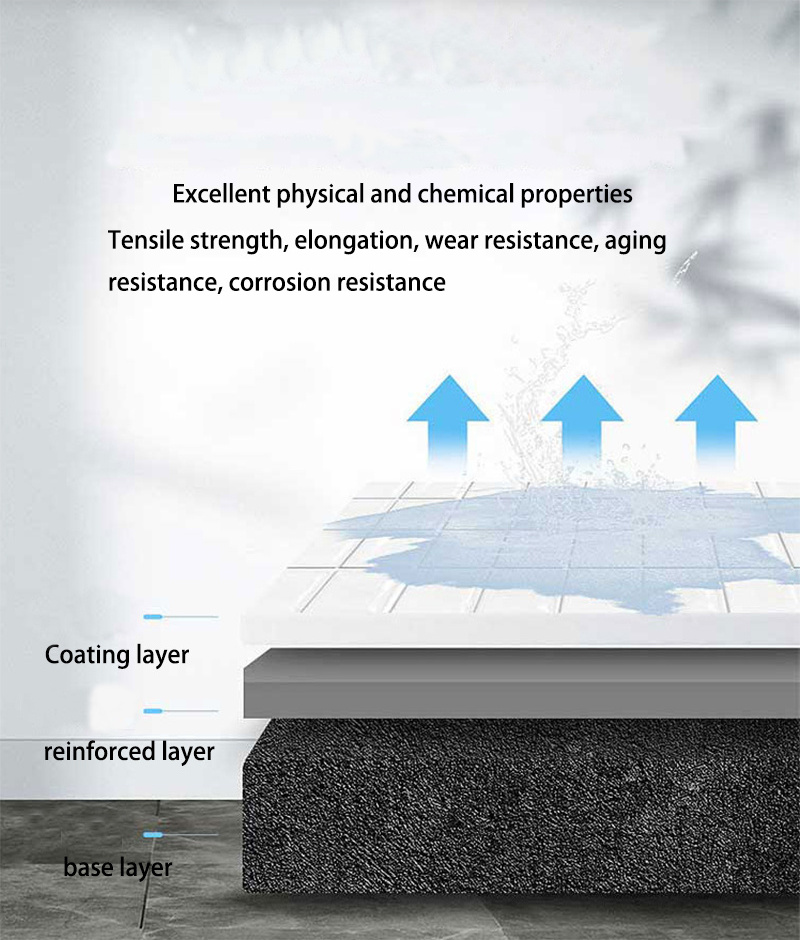

Spray polyurea elastic waterproof coating is a ready-made spray forming two-component elastic coating composed of A and B, and

group A is a semi-prepolymer prepared by reaction of isocyanate and oligomer dihydric alcohol or ternary alcohol;Group B is

composed of terminal amino resin or terminal hydroxyl resin, liquid ammonia chain extender, pigment, filler and auxiliary agent。

Components A and B are transported to the spray gun through the calculation pump of the special spraying equipment, which is

quickly mixed and sprayed onto the base surface, and the rapid reaction is consolidated into a flexible and tough waterproof,anti-corrosion and wear-resistant coating

group A is a semi-prepolymer prepared by reaction of isocyanate and oligomer dihydric alcohol or ternary alcohol;Group B is

composed of terminal amino resin or terminal hydroxyl resin, liquid ammonia chain extender, pigment, filler and auxiliary agent。

Components A and B are transported to the spray gun through the calculation pump of the special spraying equipment, which is

quickly mixed and sprayed onto the base surface, and the rapid reaction is consolidated into a flexible and tough waterproof,anti-corrosion and wear-resistant coating