PSA oxygen generator plant is fabricated using advanced Pressure Swing Adsorption technology. As is well-known, oxygen constitutes

around 20-21% of atmospheric air. PSA oxygen generator used Zeolite molecular sieves to separate the oxygen from the air. Oxygen

with high purity is delivered whereas the nitrogen absorbed by the molecular sieves is directed back into the air through the

exhaust pipe.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1200 KG

-

Marketing Type:

-

New Product 2022

-

Product name:

-

PSA nitrogen generator

-

Model:

-

FKN-49-10

-

production:

-

nitrogen

-

Capacity:

-

3-1000m3/h

-

Purity:

-

99.99%

-

Output Pressure:

-

0~0.6MPa

-

Color:

-

Grey

-

Working medium:

-

air

-

MOQ:

-

1

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Fanke

-

Voltage:

-

220v/380v/customized

-

Weight:

-

1200 KG

-

Marketing Type:

-

New Product 2022

-

Product name:

-

PSA nitrogen generator

-

Model:

-

FKN-49-10

-

production:

-

nitrogen

-

Capacity:

-

3-1000m3/h

-

Purity:

-

99.99%

-

Output Pressure:

-

0~0.6MPa

-

Color:

-

Grey

-

Working medium:

-

air

-

MOQ:

-

1

Production Information

|

Product Name

|

PSA Nitrogen Generator

|

|

Model Number

|

FKN-49-5;FKN-49-20;FKN-49-50;FKN-49-100;FKN-49-200

|

|

Nitrogen Production

|

3~2000Nm3/h

|

|

Nitrogen Purity

|

95~99.999%

|

|

Nitrogen Pressure

|

0.1~0.8Mpa

|

|

Dew Point

|

≤-45 degree

|

Products Description

Specifications

|

Specification

|

Output (Nm3/h)

|

Effective gas consumption ( Nm3/min )

|

Air cleaning system

|

Inlet/outlet caliber(mm)

|

|

FKN59-5

|

5

|

0.78

|

KJ-1

|

DN25/DN15

|

|

FKN59-10

|

10

|

1.75

|

KJ-2

|

DN25/DN15

|

|

FKN59-20

|

20

|

3.55

|

KJ-6

|

DN40/DN15

|

|

FKN59-30

|

30

|

5.25

|

KJ-6

|

DN40/DN25

|

|

FKN59-40

|

40

|

7.0

|

KJ-10

|

DN50/DN25

|

|

FKN59-50

|

50

|

8.7

|

KJ-10

|

DN50/DN25

|

|

FKN59-60

|

60

|

10.5

|

KJ-12

|

DN50/DN32

|

|

FKN59-80

|

80

|

13.75

|

KJ-20

|

DN65/DN40

|

|

FKN59-100

|

100

|

16.64

|

KJ-20

|

DN65/DN40

|

|

FKN59-150

|

150

|

24.91

|

KJ-30

|

DN80/DN40

|

|

FKN59-200

|

200

|

33.37

|

KJ-40

|

DN100/DN50

|

|

FKN59-300

|

300

|

49.82

|

KJ-60

|

DN125/DN50

|

Tel/Whatsapp/Wechat: +86 13958625869

E-mail:

bob@z-oxygen.com

1. The first cryogenic 50m3 cryogenic oxygen production equipment in Ethiopia

50 cubic meters of cryogenic oxygen was shipped to Ethiopia in December 2020. The equipment, the first of its kind in Ethiopia,

has already arrived in the country. Under construction and installation.

50 cubic meters of cryogenic oxygen was shipped to Ethiopia in December 2020. The equipment, the first of its kind in Ethiopia,

has already arrived in the country. Under construction and installation.

2. PSA oxygen generator

various oxygen suppliers in Peru asked our company to purchase several PSA oxygen generators and oxygen cylinders.

various oxygen suppliers in Peru asked our company to purchase several PSA oxygen generators and oxygen cylinders.

3. Workshop

Our precision designing makes our industrial gas systems reliable and efficient resulting in low operational costs. Being

manufactured with high quality materials and components, our liquid oxygen plants lasts for a very long time requiring minimum

maintenance. For our compliance with strict quality control measures, we have been awarded with acclaimed certifications like ISO

9001,ISO13485 and CE.

Our precision designing makes our industrial gas systems reliable and efficient resulting in low operational costs. Being

manufactured with high quality materials and components, our liquid oxygen plants lasts for a very long time requiring minimum

maintenance. For our compliance with strict quality control measures, we have been awarded with acclaimed certifications like ISO

9001,ISO13485 and CE.

Applications

PSA nitrogen generator, PSA Oxygen purifier, PSA nitrogen purifier, hydrogen generator, VPSA oxygen generator,Membrane oxygen

generator, Membrane nitrogen generator, Liquid (cryogenic) oxygen, nitrogen and argon generator, etc,and are widely used in

industries of petroleum, oil & gas, chemicals, electronics, metallurgy, coals, pharmaceuticals, aerospace,

autos, glass, plastics, food, medical treatment, grain, mining, cutting, welding, new material, etc. With years research in air

separation technology and rich solution experiences in various industries, sticks to providing our clients with more reliable,

more economical, more convenient professional gas solutions.

generator, Membrane nitrogen generator, Liquid (cryogenic) oxygen, nitrogen and argon generator, etc,and are widely used in

industries of petroleum, oil & gas, chemicals, electronics, metallurgy, coals, pharmaceuticals, aerospace,

autos, glass, plastics, food, medical treatment, grain, mining, cutting, welding, new material, etc. With years research in air

separation technology and rich solution experiences in various industries, sticks to providing our clients with more reliable,

more economical, more convenient professional gas solutions.

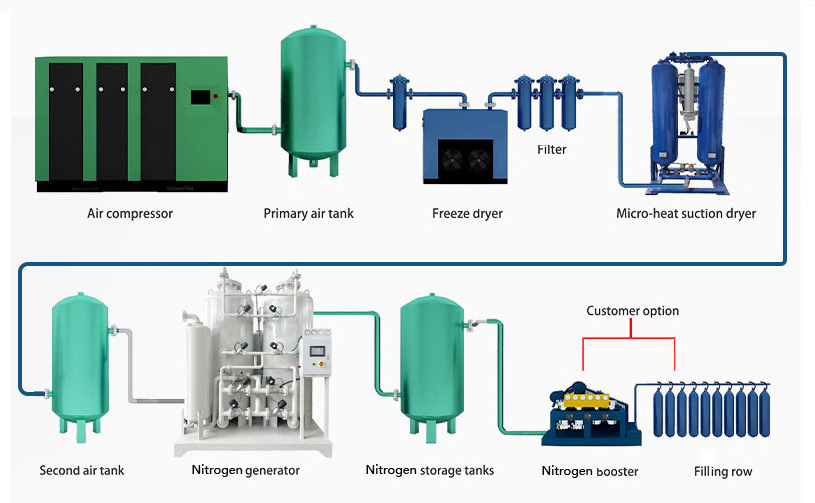

Principle of Operation

The nitrogen generators are constructed according to the principle of operation P.S.A. (Pressure Swing Adsorption) and are

composed by a minimum of two adsorbers filled up with molecular sieve.The absorbers are crossed alternatively by the compressed

air (previously purified in order to eliminate oil, humidity and powders) and produce nitrogen. While a container, crossed by the

compressed air, produces gas, the other regenerates itself losing to pressure atmosphere the gases previously adsorbed. The

process comes repeated in cyclical way. The generators are managed by a PLC.

composed by a minimum of two adsorbers filled up with molecular sieve.The absorbers are crossed alternatively by the compressed

air (previously purified in order to eliminate oil, humidity and powders) and produce nitrogen. While a container, crossed by the

compressed air, produces gas, the other regenerates itself losing to pressure atmosphere the gases previously adsorbed. The

process comes repeated in cyclical way. The generators are managed by a PLC.

Technical Features

PSA Nitrogen Generator is a nitrogen generation equipment adopting carbon molecular sieve as adsorbent - pressurized adsorption of

oxygen from the air, resulting in the separation of nitrogen.

Carbon molecular sieve's O2 and N2 adsorption properties with the increasing of adsorption pressure makes O2, N2 adsorption

capacity increased, and the adsorption rate of O2 is higher. PSA nitrogen generators exactly utilize these features of

nitrogen,oxygen and CMS. But this is not enough, many factors shall be considered and manipulated to the best - this is also why

PSA nitrogen generators are welcome and so popular in the world because do everything the best. PSA cycle is short - O2, N2

adsorption start from equilibrium/pressure equalization, but the O2, N2 diffusion/adsorption rate are so different that O2

adsorption capacity in a short time is much higher than the adsorption capacity of N2. PSA Nitrogen generation technology is using

carbon molecular sieve's adsorption characteristics, and the principle of pressurized adsorption, adsorption decompression cycle -

the compressed air alternately goes into two adsorption towers to achieve air separation, thereby producing a continuous flow of

product nitrogen. However knowing these is not enough - had developed all these to the best in all PSA nitrogen generators.

oxygen from the air, resulting in the separation of nitrogen.

Carbon molecular sieve's O2 and N2 adsorption properties with the increasing of adsorption pressure makes O2, N2 adsorption

capacity increased, and the adsorption rate of O2 is higher. PSA nitrogen generators exactly utilize these features of

nitrogen,oxygen and CMS. But this is not enough, many factors shall be considered and manipulated to the best - this is also why

PSA nitrogen generators are welcome and so popular in the world because do everything the best. PSA cycle is short - O2, N2

adsorption start from equilibrium/pressure equalization, but the O2, N2 diffusion/adsorption rate are so different that O2

adsorption capacity in a short time is much higher than the adsorption capacity of N2. PSA Nitrogen generation technology is using

carbon molecular sieve's adsorption characteristics, and the principle of pressurized adsorption, adsorption decompression cycle -

the compressed air alternately goes into two adsorption towers to achieve air separation, thereby producing a continuous flow of

product nitrogen. However knowing these is not enough - had developed all these to the best in all PSA nitrogen generators.

Recommend Products

PSA Oxygen GENERATOR

LIQUID OXYGEN & NITROGEN GENERATOR

Our medium size oxygen/nitrogen plants are designed and manufactured with the latest cryogenic air separation technology, which is

trusted as the most efficient technology for high rate of gas generation with high purity. We have world-class engineering

expertise enabling us to build industrial gas systems in compliance with internationally approved manufacturing and designing

standards.

trusted as the most efficient technology for high rate of gas generation with high purity. We have world-class engineering

expertise enabling us to build industrial gas systems in compliance with internationally approved manufacturing and designing

standards.

VPSA OXYGEN GENERATOR

PSA oxygen generator uses zeolite molecular sieve as the adsorbent, and uses the principle of pressure adsorption and

decompression desorption to adsorb and release oxygen from the air, thereby separating oxygen from the automatic equipment. N2

molecules have a faster diffusion rate in the micropores of zeolite molecular sieve, and O2 molecules have a slower diffusion

rate.

decompression desorption to adsorb and release oxygen from the air, thereby separating oxygen from the automatic equipment. N2

molecules have a faster diffusion rate in the micropores of zeolite molecular sieve, and O2 molecules have a slower diffusion

rate.

Hot Searches