- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

500kg

-

Weight (KG):

-

200 KG

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

THRIVE

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1800*700*1500

-

Power (kW):

-

22 kW

-

Certification:

-

CE,ISO

Quick Details

-

Barrel Volume (L):

-

6

-

Max. Loading Volume (L):

-

8 L

-

Range of Spindle Speed(r.p.m):

-

16 - 20 r.p.m

-

Max. Loading Capacity:

-

500kg

-

Weight (KG):

-

200 KG

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

THRIVE

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1800*700*1500

-

Power (kW):

-

22 kW

-

Certification:

-

CE,ISO

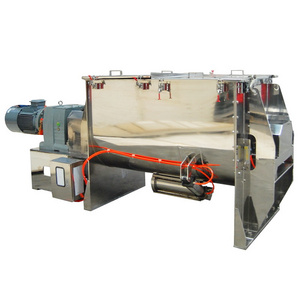

Horizontal Screw Powder Agitator Paddle Horizontal Ribbon Mixer/Liquid Powder Mixing Equipment/Industrial Food Mixing Tanks

This machine is horizontal screw belt mixer, its function is to mix all kinds of powder and liquid evenly, with wide applicability, good mixing degree, less material residue, convenient maintenance, it is an ideal equipment for powder mixing processing.

Double spiral blades are arranged on the transmission spindle of the mixer. The internal spiral transfers the materials to the outside and the external spiral gathers the materials to the inside. Under the convective movement of the double spiral belt, the materials form a mixed environment with low power and high efficiency. The inner and outer diameter spiral mounted on the stirring shaft drives the materials inside the barrel, making the stirrer turn the materials inside the barrel to the largest extent. When the stirring device works, the materials near the axis are driven by the internal spiral to rotate, and the materials near the cylinder wall are driven by the external spiral to rotate, and the materials are driven by the axial direction from both sides to the inside. The mixed materials can be evenly mixed in a short time.

Material requirements:

According to the material situation, users can choose ordinary carbon steel and stainless steel material, if the material side properties are large, then you can choose high quality stainless steel material or lining corrosion resistant layer, according to the material level requirements of surface treatment can be rough polishing, fine polishing, mirror polishing.

stainless steel

stainless steel

carbon steel

Horizontal mixing machine discharging mode:

The powder material adopts pneumatic large door structure, which has the advantages of fast unloading and no residual, etc. : manual butterfly valve or pneumatic butterfly valve is used for high fineness material or semi-fluid material. Manual butterfly valve is economical and suitable. Jackets are available where heating or cooling is required. There are two ways of heating: electric heating and heat conducting oil heating: electric heating is convenient, single heating speed is slow, high energy consumption; Heat conducting oil heating needs to be equipped with oil pot, oil conducting power and pipeline, with large investment, fast single heating rate and low energy consumption. Cooling technology can directly inject cooling water into the jacket, with large heat transfer area and fast cooling speed. The motor and stirring spindle are directly connected by cycloidal pinwheel reducer, which is simple in structure, reliable in operation and convenient in maintenance.

Parameters

| specifications | TH-1.0 | TH-2.0 | TH-3.0 | TH-4.0 |

| blend(kg) | 800 | 1600 | 2400 | 3200 |

| The motor power(kw) | 7.5 | 15 | 18.5 | 22 |

| Equipment weight(kg) | 1000 | 2300 | 2900 | 4800 |