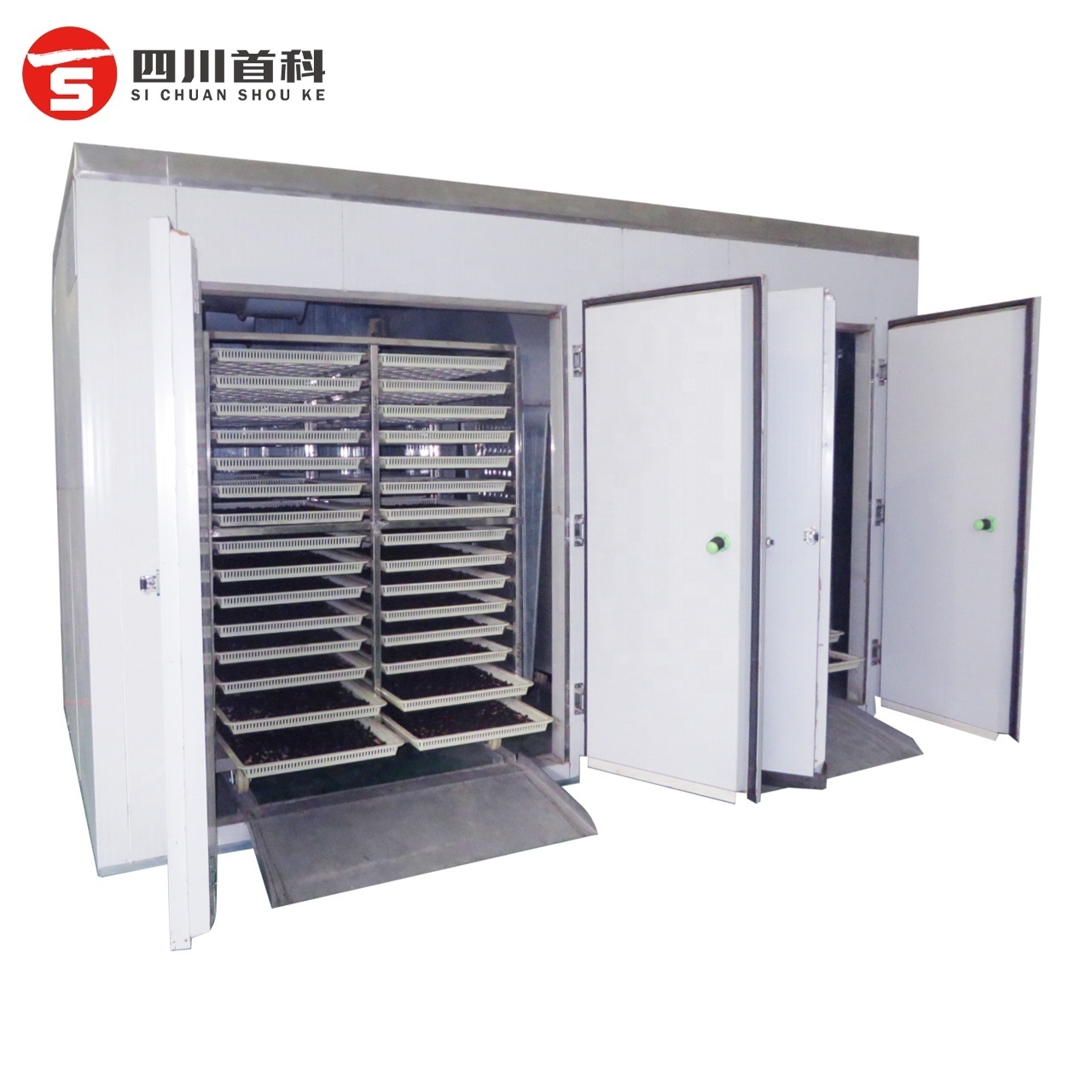

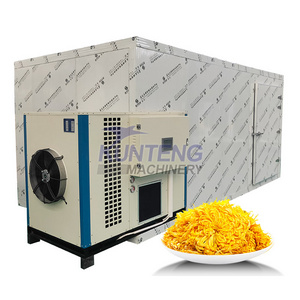

Introduction of heat pump dryer parts

1 centrifugal fan

2 High temperature electric wind valve

3 External rotor fan

4 baking room

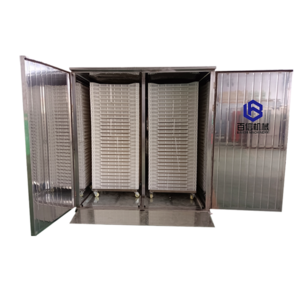

5 Stainless steel drying frame

6 304 stainless steel plate

7 Stainless steel door handle

8 High temperature dehumidifier

9 compressordoor

10 heat exchanger

11 Schneider Electric

12 touch screen

13 Plastic network location

14 circulating fan

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

20kw

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

1000

-

Marketing Type:

-

New Product 2022

-

Name:

-

dryer oven

-

Raw material:

-

Multiple Material

-

Function:

-

Food Vegetable Fruit Dehydrator

-

Material:

-

Stainless Steel

-

Heating source:

-

Electricity Steam Oil Gas

-

Usage:

-

Reduce Material's Moisture

-

Installation:

-

Engineers Support Installation

-

Heating:

-

Electric Heating Drying Oven

Quick Details

-

Type:

-

Drying Oven

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

ShouChuang

-

Voltage:

-

380v

-

Power:

-

20kw

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

1000

-

Marketing Type:

-

New Product 2022

-

Name:

-

dryer oven

-

Raw material:

-

Multiple Material

-

Function:

-

Food Vegetable Fruit Dehydrator

-

Material:

-

Stainless Steel

-

Heating source:

-

Electricity Steam Oil Gas

-

Usage:

-

Reduce Material's Moisture

-

Installation:

-

Engineers Support Installation

-

Heating:

-

Electric Heating Drying Oven

Product Description

The tray type heat pump dryer machine adopts a fully enclosed structure. Under the action of forced ventilation, the hot air

circulates in the drying room to reasonably discharge hot and humid air and replenish fresh air. It has high thermal efficiency and saves energy consumption, which makes the materials dry evenly and shortens the drying time.

circulates in the drying room to reasonably discharge hot and humid air and replenish fresh air. It has high thermal efficiency and saves energy consumption, which makes the materials dry evenly and shortens the drying time.

1.The heat pump drying machine is equipped with an automatic temperature control system with precise temperature control.

2. The heat pump drying equipment is equipped with an adjustable air distribution plate in the drying room, which uses forced ventilation to make the relative temperature more uniform.

3.The heat pump dehydrator adopts a low-noise and energy-saving built-in long-axis circulating fan, which is balanced in operation and greatly reduces the noise and heat loss of the equipment.

4. The heat pump tray dryer is equipped with a forced dehumidification centrifugal fan, which can regularly discharge the hot and humid air in the drying chamber and achieve energy saving while speeding up the efficiency.

5. The heat pump cabinet dryer has a wide range of heat sources, not only heat pumps can be used, but also electricity, steam, hot blast stoves, biomass, etc.

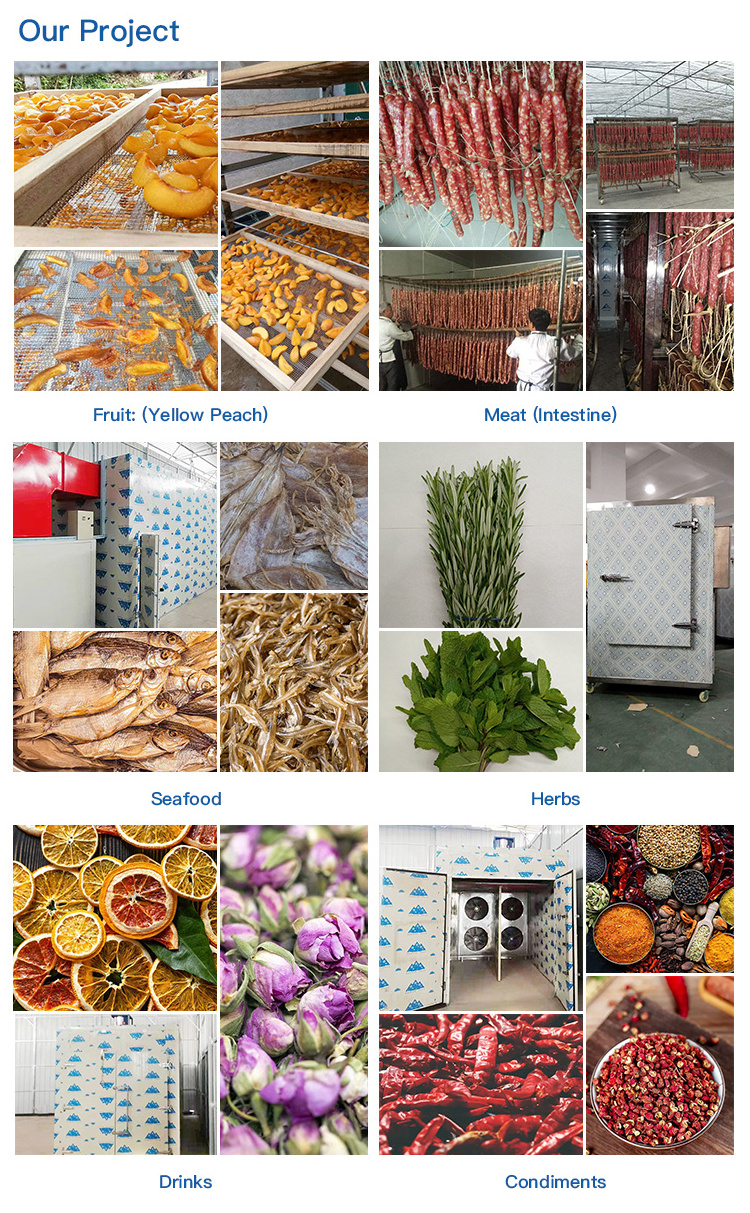

Widely Used by heat pump tray cabinet dryer

Fruits:

dried mangoes, dried preserves, lychees, longan, figs, banana slices;

Vegetables:

mushrooms, carrots, day lily, dried bamboo shoots, sweet potatoes, okra, cassava;

Herbs: ginseng, trauma, codonopsis, astragalus, Rhodiola, Ganoderma, wolfberry;

Spicy: chili, garlic, ginger, cinnamon, onion;

Seafood: squid, cod, catfish, sardine fish, octopus, cuttlefish, abalone, anchovies, sea-slug, leech, sea cucumber, scallop;

Meat food: sausage, ham, dried duck, dried beef, air-dried chicken, air-dried duck, air-dried goose, cured chicken legs, chicken wings, bacon;

Wood: mahogany, rosewood, toon, walnut, cypress, rosewood, etc.

Herbs: ginseng, trauma, codonopsis, astragalus, Rhodiola, Ganoderma, wolfberry;

Spicy: chili, garlic, ginger, cinnamon, onion;

Seafood: squid, cod, catfish, sardine fish, octopus, cuttlefish, abalone, anchovies, sea-slug, leech, sea cucumber, scallop;

Meat food: sausage, ham, dried duck, dried beef, air-dried chicken, air-dried duck, air-dried goose, cured chicken legs, chicken wings, bacon;

Wood: mahogany, rosewood, toon, walnut, cypress, rosewood, etc.

Product Paramenters

|

Model

|

5HF4

|

5HF6

|

5HF8

|

5HF10

|

5HF12

|

||||

|

Trolley

|

4 cars

|

6 cars

|

8 cars

|

10 cars

|

12 cars

|

||||

|

Tray Total

|

60 trays

|

90 trays

|

120 trays

|

150 trays

|

180 trays

|

||||

|

Tray Size(mm)

|

1400*900

|

1400*900

|

1400*900

|

1400*900

|

1400*900

|

||||

|

Tray Capacity (Kg)

|

12-20

|

12-20

|

12-20

|

12-20

|

12-20

|

||||

|

Tray Material

|

Plastic, Stainless Steel 304,304L,316

|

|

|

|

|

||||

|

Capacity (kg)

|

600-1000

|

1000-2000

|

1500-2500

|

1800-3000

|

2000-4000

|

||||

|

|

|

|

|

|

|

||||

|

Chamber Dimension (m³)

|

5.0*2.3*2.0

|

6.6*2.3*2.0

|

8.0*2.3*2.0

|

7.0*3.3*2.0

|

8.0*3.3*2.0

|

||||

|

Temperature (℃)

|

40-70℃ adjustable

|

|

|

|

|

||||

|

Heat Source

|

Heat pump, electric heating, biomass or according to customer needs

|

|

|

|

|

||||

Product Types

Different types and sizes of dryers can be customized according to customers' drying needs, and different heat sources such as power supply, natural gas, diesel, biomass particles, heat pump can be provided for customers to choose and

use. Once

designed, the scheme is directly related to transportation, installation and other links, so as to meet the diversified needs of customers as much as possible and reduce the investment and expenditure of customers

.

Company Introduction

Sichuan Nanchong Shouchuang Technology Development Co., Ltd is a service provider focusing on comprehensive processing solutions for agricultural products.It is a high-tech enterprise.It is committed to helping customers solve the problem of storage and collection of agricultural products,put an end to processing pollution and preserve the quality of agricultural products.

The company adheres to the concept of "environmental protection, energy conservation and safety", and adheres to the enterprise spirit of "taking responsibility bravely and pursuing excellence". From micro machinery to large-scale complete processing system, through advanced technology, software, equipment and services, it helps the industrial optimization and helps customers optimize their operation. Its products cover fruits and vegetables, drinks, feed and food processing and other fields.

Why Choose Us ?

Excellent equipment is the foundation of enterprise development:

Using the professional air pipe nesting software of auto desk company, cooperating with the special tools of German tongkuai air pipe, American feimat generator, automatic plasma cutting, numerical control punch press and other hardware, it is easy to deal with various complex model structures.

50 years of drying experience, founded in 1972 in China;

60+ national patents and copyrights;

30000+ square meter factory area;

60+ exported to about 60 countries;

200+ managers,sales and technicians;

4+ manufacturing bases (in 2*Sichuan(panda hometown),1*Foshan,1*Guizhou province)

6000+ domestic and foreign customer cases ,including complete drying processing lines,involving fruits(wolfberry,jujube,avocado),vegetables(konjac, cassava,mushroom), seafood(stock, anchovy, squid),condiments(pepper, garlic,ginger), flowers(rose, honeysuckle), Chinese herbal medicine and other materials;

60+ national patents and copyrights;

30000+ square meter factory area;

60+ exported to about 60 countries;

200+ managers,sales and technicians;

4+ manufacturing bases (in 2*Sichuan(panda hometown),1*Foshan,1*Guizhou province)

6000+ domestic and foreign customer cases ,including complete drying processing lines,involving fruits(wolfberry,jujube,avocado),vegetables(konjac, cassava,mushroom), seafood(stock, anchovy, squid),condiments(pepper, garlic,ginger), flowers(rose, honeysuckle), Chinese herbal medicine and other materials;

Automatic Complete Drying Processing Line Cases

Fruit Pulp Pomace Drying Production Line

The mesh belt dryer with a daily treatment capacity of 100 tons of fruit residue is used for drying and recycling the fruit residue after juicing, which can meet the requirements of environmental protection, greatly improve the utilization rate of products, extend the industrial value, and improve the processing income of customers.

Red Dates Drying Production Line

Automatic jujube grading, cleaning, air drying, drying, packaging production line. Equipped with classifier, spray cleaner, air dryer, mesh belt dryer, packaging machine and other automatic production equipment. The unique waste heat design of recovered products is adopted to further reduce energy consumption and energy cost investment. Support customized different material production line.

Konjac Chips Drying Production Line

Konjac processing process mainly includes fresh konjac cleaning, slicing, improve input, drying, unloading, packaging and so on.

Konjac dryer can solve the problem of konjac drying, such as konjac high water content, complex composition, easy to change the color and other characteristics, the development of production and sales of automatic drying equipment, drying effect is good,taro white, dry quality.

Konjac dryer can solve the problem of konjac drying, such as konjac high water content, complex composition, easy to change the color and other characteristics, the development of production and sales of automatic drying equipment, drying effect is good,taro white, dry quality.

Chili Pepper Drying Production Line

The Chili deep processing production line workflow: chili drying - removal impurity - stem cutting -color selection- secondary drying- dry cleaning - cut (optional) - skin seed separation (optional) - secondary removal impurity- grinding (optional)-packaging.

The pepper processing line includes pepper dryer, pepper air drying machine (optional), pepper color separation machine, pepper tail removal machine, pepper grinder, pepper packaging machine and other equipment. Pepper processing line can also be used for garlic, ginger, scallions and other spices processing.

The pepper processing line includes pepper dryer, pepper air drying machine (optional), pepper color separation machine, pepper tail removal machine, pepper grinder, pepper packaging machine and other equipment. Pepper processing line can also be used for garlic, ginger, scallions and other spices processing.

Alfalfa Hay Grass Drying Processing Line

Automatic mechanical drying equipment

Fodder dryer

can realize automatic production of heating, feeding, feeding, drying, unloading and other processes. The entire production line only needs 1~2 workers, which effectively controls the labor cost.

High performance feed drying equipment

Grass dryer is simple to use, convenient performance, safe and stable, can work continuously for 24 hours, less failure, low maintenance cost. The dryer allows the grass to dehydrate quickly and meet the drying requirements of the finished product.

With high air tightness and heat insulation

For feed drying equipment, a good closed system and insulation device are needed to reduc

e energy consumption and cost.

Customer Photos

Package & Shippment

Hot Searches