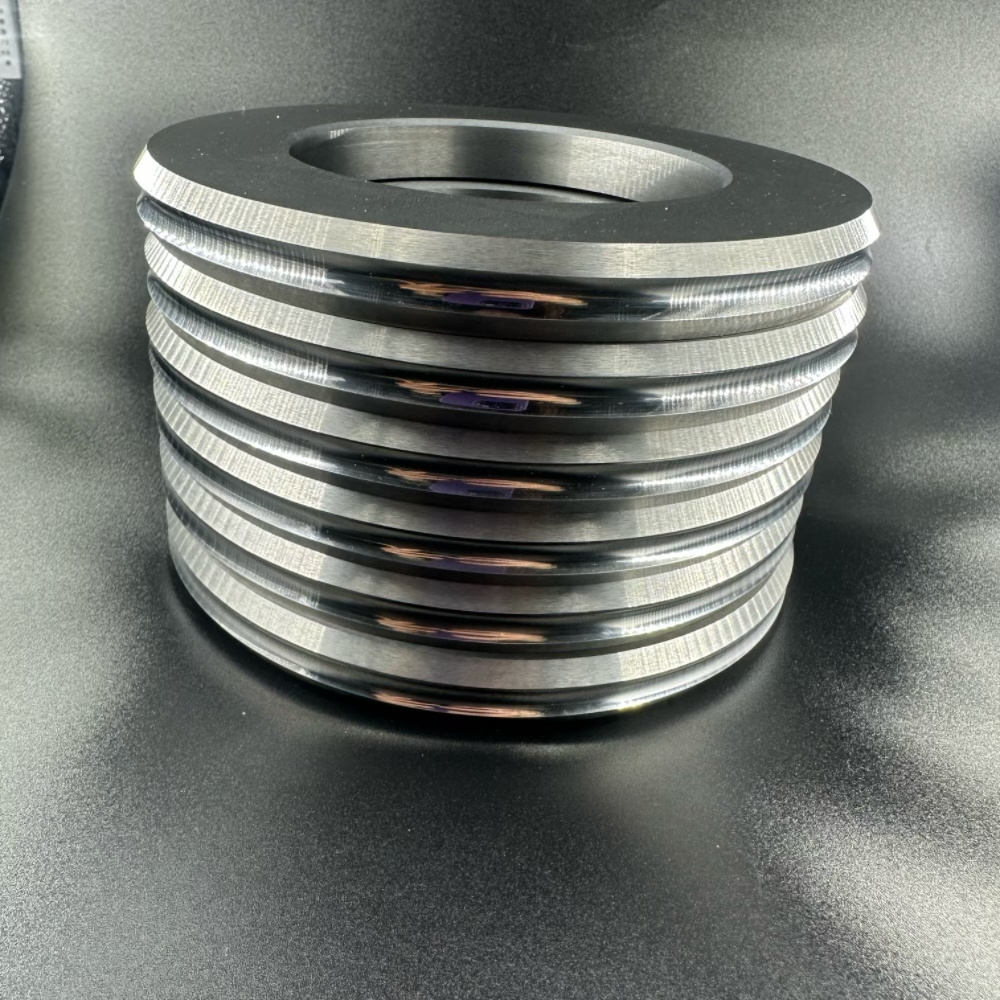

Tungsten carbide rollers are available in both integral and combined versions. They have excellent performance, stable quality, high processing precision,

good wear resistance, and high impact resistance.

The tungsten cemented carbide rollers have high hardness, and its hardness changes very little with temperature changes.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

RO RT FO PR

-

Particle:

-

1.0-1.2 um

-

Product name:

-

Tungsten carbide rolling ring rolls rollers

-

Material:

-

100% original WC+CO

-

Type:

-

Powder metallurgy

-

Advantage:

-

High hardness,strength, wear resistance,high abrasion

-

Grade:

-

YG15

-

Usage:

-

rolling machine, rolling mills, cold rolled rebar

-

Density:

-

13.5g/cm3

-

Hardness:

-

83~87 HRA

-

Size:

-

Customized Size

-

Certificate:

-

ISO9001

Quick Details

-

Alloy Specification:

-

YG15

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HengRui

-

Model Number:

-

RO RT FO PR

-

Particle:

-

1.0-1.2 um

-

Product name:

-

Tungsten carbide rolling ring rolls rollers

-

Material:

-

100% original WC+CO

-

Type:

-

Powder metallurgy

-

Advantage:

-

High hardness,strength, wear resistance,high abrasion

-

Grade:

-

YG15

-

Usage:

-

rolling machine, rolling mills, cold rolled rebar

-

Density:

-

13.5g/cm3

-

Hardness:

-

83~87 HRA

-

Size:

-

Customized Size

-

Certificate:

-

ISO9001

Products Description

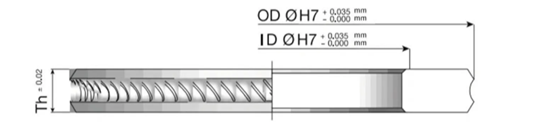

Stock standard sizes 150*95*15mm tungsten carbide roller rings carbide cold roller for TMT bars

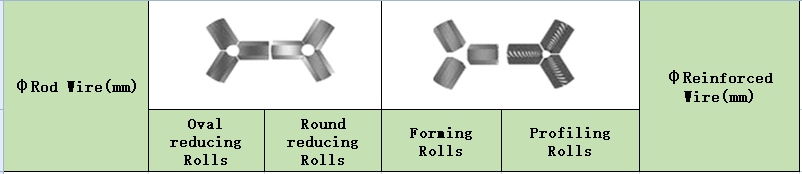

Our Sizing ,forming,reducing and profiling rolls are made of either tungsten carbide or steel and are used to produce smooth or ribber wire for the construction field.

Profiling rolls, tungsten carbide rolls for wire ribbing, according to different standard and demands of the market.rolls include PR,CA,RT, RO,FO type.

Also could make it as per customer requirements.

https://www.ihrcarbide.com/

|

Standard Size

|

|

|

|

|||

|

Wire diameter(mm)

|

OD(mm)

|

ID(mm)

|

Thickness(mm)

|

|||

|

4.0~8.5

|

125

|

82

|

15

|

|||

|

9.0~12.0

|

125

|

82

|

20

|

|||

|

4.0~8.5

|

140

|

90

|

15

|

|||

|

9.0~12.0

|

140

|

90

|

20

|

|||

|

4.0~8.5

|

150

|

90

|

15

|

|||

|

9.0~12.0

|

150

|

90

|

20

|

|||

|

4.0~8.5

|

150

|

95

|

15

|

|||

|

9.0~12.0

|

150

|

95

|

20

|

|||

|

9.0~12.0

|

170

|

100

|

20

|

|||

|

9.0~12.0

|

220

|

130

|

20

|

|||

|

4.0

|

RO0

|

RT0

|

FO0

|

PR3.0

|

3.0

|

|

4.5

|

RO0

|

RT0

|

FO0

|

PR3.5

|

3.5

|

|

5.0

|

RO1

|

RT1

|

FO1

|

PR4.0

|

4.0

|

|

5.5

|

RO1

|

RT1

|

FO1

|

PR4.5

|

4.5

|

|

6.0

|

RO2

|

RT2

|

FO1

|

PR5.0

|

5.0

|

|

7.0

|

RO2

|

RT2

|

FO1

|

PR5.5

|

5.5

|

|

7.5

|

RO3

|

RT3

|

FO2

|

PR6.0

|

6.0

|

|

8.0

|

RO3

|

RT3

|

FO2

|

PR6.5

|

6.5

|

|

8.5

|

RO4

|

RT4

|

FO2

|

PR7.0

|

7.0

|

|

9.0

|

RO4

|

RT4

|

FO3

|

PR7.5

|

7.5

|

|

10

|

RO5

|

RT5

|

FO3

|

PR8.0

|

8.0

|

|

11

|

RO5

|

RT5

|

FO3

|

PR8.5

|

8.5

|

|

11

|

RO5

|

RT5

|

FO3

|

PR9.0

|

9.0

|

|

12

|

RO6

|

RT6

|

FO4

|

PR9.5

|

9.5

|

|

12

|

RO6

|

RT6

|

FO4

|

PR10.0

|

10.0

|

|

13

|

RO6

|

RT6

|

FO4

|

PR10.5

|

10.5

|

|

14

|

RO7

|

RT7

|

FO4

|

PR11.0

|

11.0

|

|

14

|

RO7

|

RT7

|

FO4

|

PR11.5

|

11.5

|

|

15

|

RO7

|

RT7

|

FO4

|

PR12

|

12.0

|

Our Company

Renqiu Hengrui Cemented Carbide Co., Ltd. was founded in 2006 and deepened its reform in 2008. In 2019, the company established the company's core values of "integrity, ingenuity, sharing, responsibility, and win-win" and actively practiced "serving the interests of the three parties" to "build a new era of dreams, create a new future with intelligence, and strive to create intelligent manufacturing, green The new Hengrui brand manufactured by Hengrui is committed to becoming the leader in the carbide mold industry as its corporate vision; it strives to provide customers with thoughtful and satisfactory services, achieve sustained capital appreciation for the company, become bigger and stronger, and build a good career for employees. Development platform, promotes brand development in the alloy industry, enhances the image of Made in China, and contributes to social harmony. Company mission.

Mechanical Equipment

We have a high-quality team with rich production experience and excellent technology. Currently there are 3 senior senior consultants, 1 senior engineer, 2 senior engineers, and 6 professional technicians.

Implement "7S" management. "7S" management has been implemented from the five aspects of people, machines, materials, methods and environment; each type of product is equipped with professional sales engineers to provide technical services; there is a standardized personnel management system and a complete management system, which is the best in the industry Have high visibility and influence.

Production Process

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Quality Assurance

Before mass production, we need to do a trial pressing and sintering , and we check the appearances and the size, density and

hardness of samples with micrometer, Metallurgical microscope,densitometer etc. to ensure that the requirements of the drawings

can be met before batch production;All the products must be inspected strictly by our QC.

Quality Assurance

Before mass production, we need to do a trial pressing and sintering , and we check the appearances and the size, density and

hardness of samples with micrometer, Metallurgical microscope,densitometer etc. to ensure that the requirements of the drawings

can be met before batch production;All the products must be inspected strictly by our QC.

Certifications

Our Team

Product packaging

Packaging and Delivery

1. Interior packaging: paper box interior

2. Exterior packaging: carton or wooden case

3. Other packaging upon your request

Shipping:

* By sea Tianjin port for big amount 15-30days.

* By Express(Fedex,DHL,UPS,TNT)for small amount around 3-7days.

2. Exterior packaging: carton or wooden case

3. Other packaging upon your request

Shipping:

* By sea Tianjin port for big amount 15-30days.

* By Express(Fedex,DHL,UPS,TNT)for small amount around 3-7days.

Hot Searches