- Product Details

- {{item.text}}

Quick Details

-

Material:

-

pallet

-

Weight:

-

540

-

Size:

-

2800mm*2000mm*1600mm, 2800mm*2000mm*1600mm

-

Power:

-

AC220V / 1.00Kw

-

Weight (KG):

-

520 kg

-

Product name:

-

Industrial RO Rolling Machine

-

Certification:

-

ISO9001

-

AIR PRESSURE:

-

1kw

-

Working temperature:

-

0~40℃ (Thebesttemperatureis25℃)

-

manpower:

-

1person,laythesheetonrightposition

-

Product model:

-

4021,4040,8040

-

Production:

-

6-8min/pc

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

India

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

WECOME

-

Material:

-

pallet

-

Weight:

-

540

-

Size:

-

2800mm*2000mm*1600mm, 2800mm*2000mm*1600mm

-

Power:

-

AC220V / 1.00Kw

-

Weight (KG):

-

520 kg

-

Product name:

-

Industrial RO Rolling Machine

-

Certification:

-

ISO9001

-

AIR PRESSURE:

-

1kw

-

Working temperature:

-

0~40℃ (Thebesttemperatureis25℃)

-

manpower:

-

1person,laythesheetonrightposition

-

Product model:

-

4021,4040,8040

-

Production:

-

6-8min/pc

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

India

Products Description

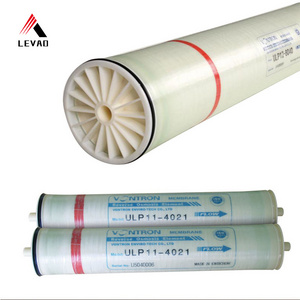

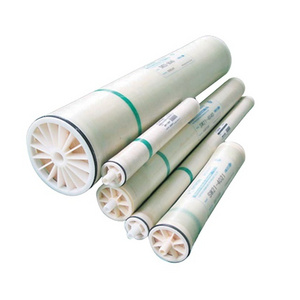

Industrial Manual Rolling Machine

Our company designed industry element rolling machine is very simple, safe and stability, it can be used for rolling 4021, 4040 and 8040 different kinds of elements.This machine we add the infrared level, that infrared ray line on carrier will help us glue dispensing straight and guide us the right dispensing position. We also add the magnetic powder tension controller to control the carrier tension, for rolling process this tension is very important, the element will be very loose without tension, and the element will leakage from the loose point.

Regular 4040 element no need to welding the carrier, only trim carrier to the formula size is enough, to 8040, due to 20 layers sheet need to glue dispensing so we need to welding the 20 layers carrier at first in case when rolling the layers position changing, that will be a big problem for us to rolling element.

Regular 4040 element no need to welding the carrier, only trim carrier to the formula size is enough, to 8040, due to 20 layers sheet need to glue dispensing so we need to welding the 20 layers carrier at first in case when rolling the layers position changing, that will be a big problem for us to rolling element.

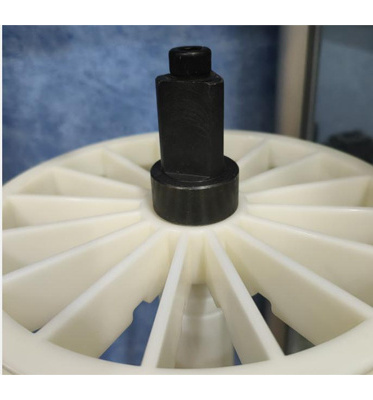

Machine Picture

Machine front side

Machine Picture

Machine back side

Precautions when use:

*Don't touch switch and and machine control component when your hand attached with resin or glue.

* For safety, use protective glasses and gloves in your work.

* Please shut down power supply of machine when stop machine.

* Strictly prohibit fire, when using resin that has peculiar smell or is harmful to human body please pay attention to ventilation.

* Kindly note that It may cause damage to machine if mistake in installation, adjustment and setting.

* Please read all the safety precautions recorded in this operation manual and follow it strictly.

* The device is designed and produced in accordance with the customer's use requirements, and absolutely not allowed to carry out the work outside the client's scheme book content, or self-remolding etc. We don’t assume any responsibility if such as self-remolding etc.

* For safety, use protective glasses and gloves in your work.

* Please shut down power supply of machine when stop machine.

* Strictly prohibit fire, when using resin that has peculiar smell or is harmful to human body please pay attention to ventilation.

* Kindly note that It may cause damage to machine if mistake in installation, adjustment and setting.

* Please read all the safety precautions recorded in this operation manual and follow it strictly.

* The device is designed and produced in accordance with the customer's use requirements, and absolutely not allowed to carry out the work outside the client's scheme book content, or self-remolding etc. We don’t assume any responsibility if such as self-remolding etc.

Control the carrier tension to make sure rolling element tight.Setting the motor rolling speed.

Once connect the power this light will be green color.

Setting the rolling motor direction.

Control the right side blade working and trim element edges.

Once connect the power this light will be green color.

Setting the rolling motor direction.

Control the right side blade working and trim element edges.

Operation introduction

a. Preparing all raw materials, trim materials and folding for ready.

b. Connect machine to air and power, and start machine.

c. Put the carrier on the machine back side air shafts, and inject air to fix carrier on position, then adjust carrier position to confirm it straight with the rolling machine work platform. Same time need to adjust the Magnetic powder tension

controller, we need to make sure the proper tension, otherwise when rolling element we can’t rolling tight, that will cause the loose element leakage.

d. Take a central tube, first need to taping two sides foam tape on tube body, and central tape on two sides of central tube. Next step need to fix the matched fixture on one side of central tube, and put this central tube on machine, press the machine right side button fix tube.

e. Remove the release paper of the two sides foam tape from the central tube body, pull carrier by manual bonding to central tube, and foot switch control let central tube rotate 1 ~ 2 layer to make sure carrier bonding tube and carrier straight.

f. Adjust Infrared level, make sure the infrared ray straight and the same distance to the both edges of the carrier, this is very important to help us to control the glue dispensing process.

g. Prepare the two component PU adhesive for rolling process, here we recommend to use machine auto-mix glue, manual mix alsopossible. We need to use bag for manual dispensing glue requirement.

h. Along the infrared ray, we need to dispensing two components PU glue on the carrier, the glue lines looks like “U” word, after first time glue dispensing finished, put the first layer folding sheet, and layer trim carrier on sheet, then again glue dispensing as first time. We need to repeat this layer sheet and glue dispensing process few times, regular a 4040

element need to repeat 5 times, and 8040 need to repeat 20 times. Next step we should control the foot switch to rolling element slowly. All process need hand holding and support, rolling speed need slow and hand tap lightly on sheet for the air easily out of the sheet. All rolling process finished we should hand holding the element keep running some time then use the bonding tape bonding element outside, release element and remove from machine.

element need to repeat 5 times, and 8040 need to repeat 20 times. Next step we should control the foot switch to rolling element slowly. All process need hand holding and support, rolling speed need slow and hand tap lightly on sheet for the air easily out of the sheet. All rolling process finished we should hand holding the element keep running some time then use the bonding tape bonding element outside, release element and remove from machine.

i. Put the rolled element on shelves or some customized plate, wait 8 hours minimum for epoxy cured. After epoxy cured we need to move the element to trim process, then after vacuum test the element, also sometimes need to water testing element by random, all the qualified element will assembly the both side cap, and move to next step for FRP.

j. After RO element FRP process need to waiting for the outside epoxy

cured, then after we need to packaging the industry element to vacuum bag and box, waiting for send to customers.

Machine Details

Machine Model: IN-MR-01

Machine Size: 2800mm*2000mm*1600mm

Machine Power: AC220V / 1.00Kw

Air Pressure: 0.6KG

Production:

Depends on labour working experience. New labor regular nee to use 20

minutes for a 8040 element, and 6~8 minutes for a 4040 element.

minutes for a 8040 element, and 6~8 minutes for a 4040 element.

Hot Searches