- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TKrobot

-

Dimensions:

-

2000*1000*200mm

-

Use:

-

Welding

-

Weight (KG):

-

550 KG

-

Product name:

-

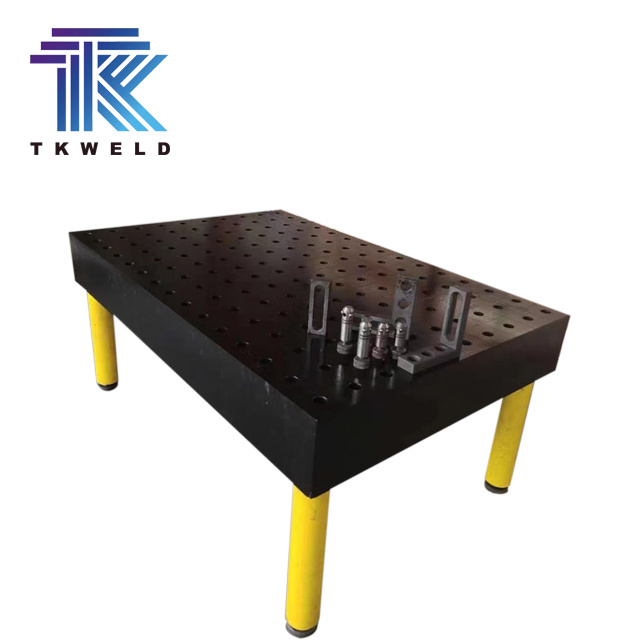

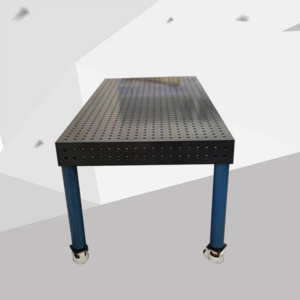

Welding Table

-

Material:

-

Cast Iron

-

Feature:

-

Economical

-

Application:

-

Welding support

-

Surface:

-

Nitrided

-

Color:

-

Grey

-

Support:

-

Fixed legs or universal wheel legs

-

Hole diameter:

-

28mm

-

MOQ:

-

1

-

Package:

-

Polywooden

Quick Details

-

Marketing Type:

-

Hot product 2023

-

Core Components:

-

Table

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

TKrobot

-

Dimensions:

-

2000*1000*200mm

-

Use:

-

Welding

-

Weight (KG):

-

550 KG

-

Product name:

-

Welding Table

-

Material:

-

Cast Iron

-

Feature:

-

Economical

-

Application:

-

Welding support

-

Surface:

-

Nitrided

-

Color:

-

Grey

-

Support:

-

Fixed legs or universal wheel legs

-

Hole diameter:

-

28mm

-

MOQ:

-

1

-

Package:

-

Polywooden

Product Description

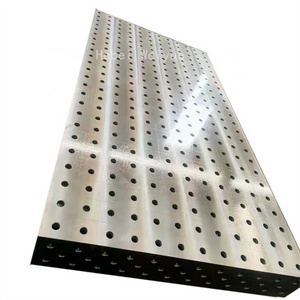

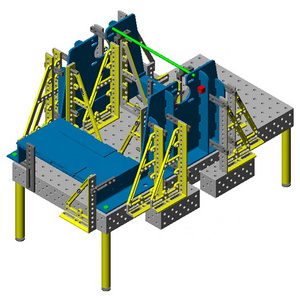

Welding Table

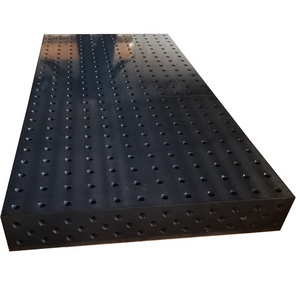

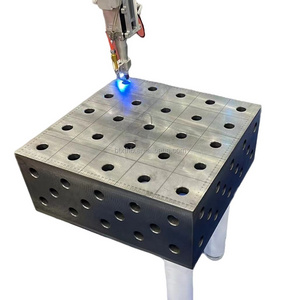

The welding table is divided into two series according to the hole system: Φ28 and Φ16. It is divided into two-dimensional flexible combination tooling and three-dimensional flexible combination tooling according to the structure. The tooling platform is divided into steel piece platform and cast iron platform according to materials. The grid is engraved with corresponding grid lines. According to customer requirements, the measuring scales can be drawn on the four sides of the platform and the surface can be nitrided.

Specification

|

Product Name

|

Size (mm)

|

Item Number

|

|

3D Steel /Cast iron Welding table

|

1000x1000x200

|

TTK2810001

|

|

|

1200x1200x200

|

TTK2810002

|

|

|

1500x1000x200

|

TTK2810003

|

|

|

1500x1500x200

|

TTK2810004

|

|

|

2000x1000x200

|

TTK2810005

|

|

|

2400x1200x200

|

TTK2810006

|

|

|

3000x1500x200

|

TTK2810007

|

|

|

4000x2000x200

|

TTK2810008

|

|

|

2000x2000x200

|

TTK2810009

|

|

|

1200x1000x200

|

TTK2810010

|

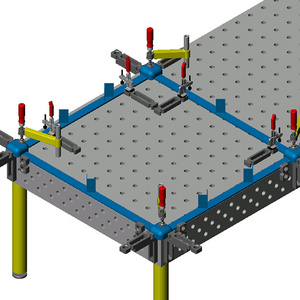

2D 3D Welding Table Features

1.

Modularity and flexibility

Can be connected and changed arbitrarily according to the shape of workpiece.

2.

High precision.

The precision can reach decimillimetre(dmm) for fixing and clamping.

3.

Quick fixing and clamping.

Only spending a few minutes to fix and clamp workpieces from one to another.

4.

Easy to operate.

Only 2 hours, any worker can learn how to use it quickly.

5.

High price-performance ratio.

1 set of modular flexible fixture can replace all traditional dedicated fixtures.

Saved a lot of time, labor, material resources and funds for enterprises.

6.

Clean, tidy and environmental Friendly.

Compared with mountains of rusty dedicated fixtures, modular flexible fixtures are the optimal choice.

1) The surface of the platform is evenly distributed with φ28 or ∅16 holes, and the welding slag can be easily cleaned through the holes.

2) Surface holes are evenly distributed. It is convenient to install the positioning fixture at any position.

3) Relying on the surface holes with uniform distribution, can insert the pressing part at any position.

4) The platform can be reused when changing the product model.

5) Strong interchangeability, high stability, high precision and high cost performance; suitable for small-volume multi- variety and multi-standard workpiece welding and product assembly.

2) Surface holes are evenly distributed. It is convenient to install the positioning fixture at any position.

3) Relying on the surface holes with uniform distribution, can insert the pressing part at any position.

4) The platform can be reused when changing the product model.

5) Strong interchangeability, high stability, high precision and high cost performance; suitable for small-volume multi- variety and multi-standard workpiece welding and product assembly.

Packing & Delivery

Hot Searches