- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

0.1kHz-20000kHz

-

Application:

-

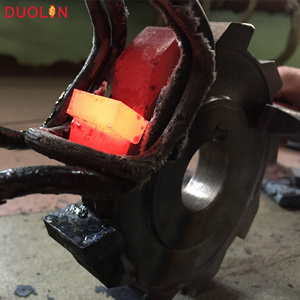

annealing,quenching,melting,welding

-

Brand:

-

RONEN

-

Certification:

-

ISO9001:2008

-

Material:

-

steel, stainless steel, aluminum, copper, titanium

-

Type:

-

Fully Automatic

-

Voltage:

-

three phase 220-660V, 50-60HZ

Quick Details

-

Place of Origin:

-

Hebei, China

-

Function:

-

induction heating

-

Power:

-

10-10000kW

-

Frequency:

-

0.1kHz-20000kHz

-

Application:

-

annealing,quenching,melting,welding

-

Brand:

-

RONEN

-

Certification:

-

ISO9001:2008

-

Material:

-

steel, stainless steel, aluminum, copper, titanium

-

Type:

-

Fully Automatic

-

Voltage:

-

three phase 220-660V, 50-60HZ

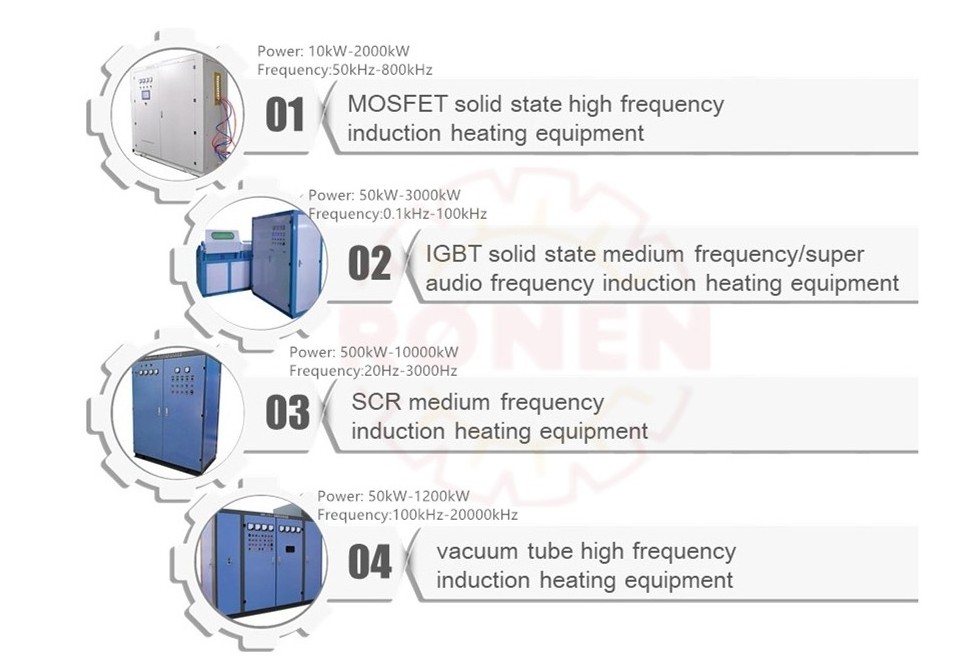

MAIN PRODUCT

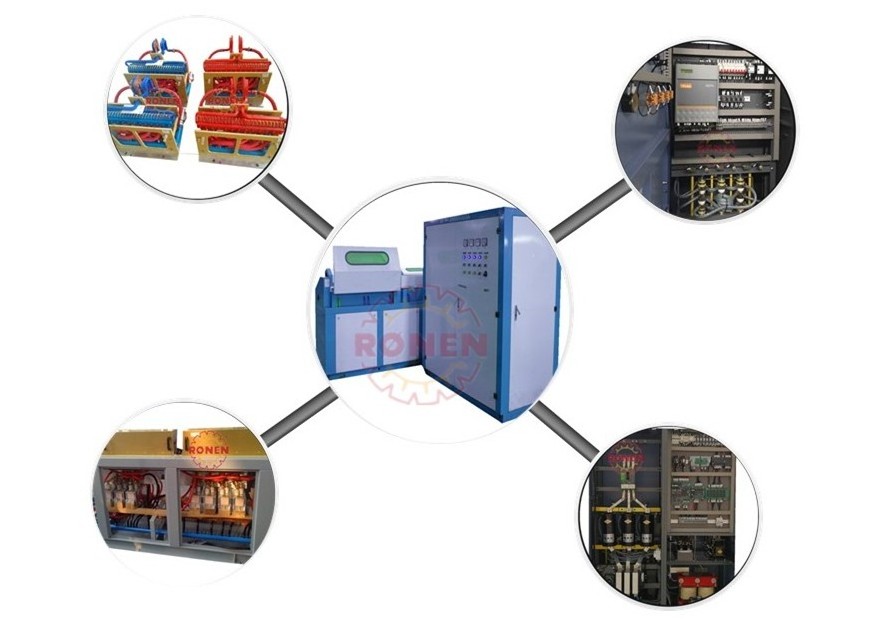

OUR SUCCESSFUL PROJECT

APPLICATION

Ronen Group co., Ltd is established at 1997, has a large modern standard industrial plant. Ronen Group is a professional mechanical equipment manufacture for design, producing and sales, our company has a group of research technicians who have many years research and development experience. We equipped with independent research and development department,design department, welding workshop, assembly workshop, checkout room, the assessment team and thorough manufacturing system etc... Ronen company passed ISO9001:2008 certification and strictly follow this system for production.etc.

OUR PRODUCT CATALOGUE

Q: Are you manufacturer?

A: Yes, We are the leading manufacturer.

Q: How to order?

A: Please send us your inquiry by email, send message though Alibaba or we chat.

Q: What is the whole business flow cooperation with us ?

A:

1. Firstly,send your inquiry to us, make us have learned your requirement

2. we will be drawing a proforma invoice according to your requirement ,and start production after you finished to pay 30% deposit.

3. All of the goods, packing details, and B/L copy will be send to buyer after finished production. We will arrange shipment and provide original B/L after the buyer finished to pay the balance.

Q: What advantages we have?

A: Rich experience: We have been in this line for 21 years . we can provide solution according to the problem of the buyer meet in the production process