- Product Details

- {{item.text}}

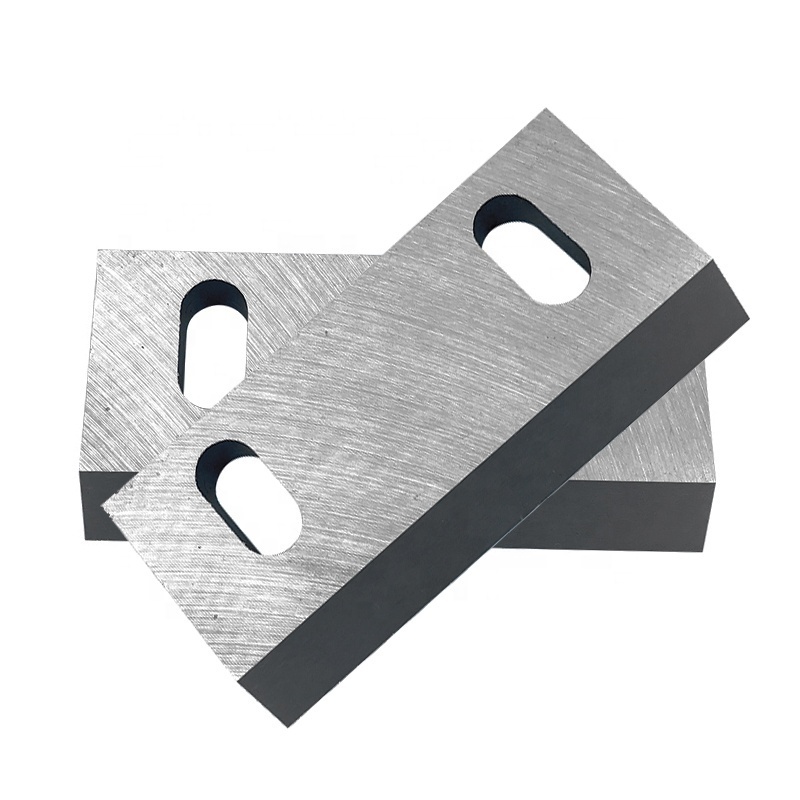

Quick Details

-

Usage:

-

textile, film industry

-

Color:

-

Silver

-

Feature:

-

Durable, Sharp, can be customized

-

Size:

-

Size Customized

-

OEM,ODM:

-

Accept

-

Application:

-

Plastic Recycling

-

Surface treatment:

-

Correct grinding

-

performance:

-

Long Life

Quick Details

-

Core Components:

-

wood cutting blade

-

Product name:

-

chipper shredder blades

-

Shape:

-

Customized Designs

-

Usage:

-

textile, film industry

-

Color:

-

Silver

-

Feature:

-

Durable, Sharp, can be customized

-

Size:

-

Size Customized

-

OEM,ODM:

-

Accept

-

Application:

-

Plastic Recycling

-

Surface treatment:

-

Correct grinding

-

performance:

-

Long Life

| 1. Blanking | Selecting material according the customers' request. |

| 2. Forging | Increasing the density of the material. |

| 3. Tempering | Lowering temperature for processing. |

| 4. Finishing machining | Making the material shaped |

| 5. Inspection | Checking the products if they are the same as the drawing. |

| 6. Hardening | Increasing the hardness of products and the material. |

| 7. Annealing | To incrase abrasion resistance, need to anneal thermal insulation for long time. |

| 8. Hardening and tempering | Hardening and tempering the parallel of products for processing. |

| 9. Coarse grinding | Coarse grinding the surface of products to be shaped. |

| 10. Accurate grinding | Supergrinding to incrase the precision and the parallel of products. |

| 11. Testing | Refusing the unqualified products into the market. |

| 12. Packaging | Different products, different packaging |

All of our materials are bought from reliable suppliers, such as Baogang China, Yishengbai from USA. And we also have material testing, to check if the materials are the correct ones. To make sure all of the materials are qualified.

Professional manufacturer of industrial blades , packaging seal jaws, packaging formers, knives , Located in Shanghai City, China (mainland) , Zhijing has been committed to the research and development of various industrial blades, the main products including: slitting machine blade, Slitter circular blade, slitting circular blade, shredder blades ,shear blades, cut flat circular knife, crusher blades, shredder blades, wood cutting blades etc .

Our packaging machinery seal jaws, formers and accessories have already surpass Germany’s and Japan’s quality. What ever the parts you are looking for, we can make innovations and produce for you. Reduce your processing lines’ costs, solve your packaging problems, make your products with a better packaging.

Our company pursuit of "super-sharp, high-precision, extremely durable" knife philosophy, dedication to create each piece of mechanical blade, from the first sheet to the first one million tutte. Let's sophisticated technology and strict attitude to provide you with top service!