- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HF

-

Voltage:

-

220V-440V

-

Dimension(L*W*H):

-

5120x1950x2810mm

-

Marketing Type:

-

Hot Product 2021

-

Weight (KG):

-

5500 kg

-

Main vibration from:

-

Platform vibration

-

Rated pressure::

-

15MPa

-

cycle time:

-

15-25s

-

Host machine power:

-

26.5kw

-

Weight:

-

5500KG

-

Qty/mould:

-

5pcs/400*200*200mm

-

Qty/8hour:

-

7200-9600pcs/400*200*200mm

-

pallet size:

-

1100*550mm

-

raw material:

-

stone,sand,cement,dust, coal fly ash,cinder,slag, industrial wastes

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

Other, 7200-9600/8 hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HF

-

Voltage:

-

220V-440V

-

Dimension(L*W*H):

-

5120x1950x2810mm

-

Marketing Type:

-

Hot Product 2021

-

Weight (KG):

-

5500 kg

-

Main vibration from:

-

Platform vibration

-

Rated pressure::

-

15MPa

-

cycle time:

-

15-25s

-

Host machine power:

-

26.5kw

-

Weight:

-

5500KG

-

Qty/mould:

-

5pcs/400*200*200mm

-

Qty/8hour:

-

7200-9600pcs/400*200*200mm

-

pallet size:

-

1100*550mm

-

raw material:

-

stone,sand,cement,dust, coal fly ash,cinder,slag, industrial wastes

Products Description

Our QT5-15 production line starts with a batching machine that weighs the raw material (sand, crushed stone and other materials)according to the customer desires ratio.

Then it transfer the materials to the mixer hopper. The mixer hopper automatically transfers the material into the mixer to make the correct formulation.

After being mixed it is poured onto the conveyor system that sends it to the block pressing machine. The block pressing machine vibrates the mixture into the desired mold and sends out the finished block on the other end on the PVC pallets.

After this it is sent to the stacker which takes the finished blocks and stacks them to be moved around the drying yard with a forklift. All this is operated by the main control panel on the opposite side of the production line and all operational equipment has safety wire screening to protect the workers. The machines comes with three different size molds and 1000 PVC pallets.

|

Technical specifications

|

|

|

|

|

||||

|

Technical Parameter

|

Platform Vibration

|

|

|

|

||||

|

Rated Pressure

|

16MPa

|

|

|

|

||||

|

Cycle time

|

15-20s

|

|

|

|

||||

|

Host Machine Power

|

26.5Kw

|

|

|

|

||||

|

Pallet Size

|

1100x550mm

|

|

|

|

||||

|

Machine Size

|

5120x1950x2810mm

|

|

|

|

||||

|

Weight

|

5500Kg

|

|

|

|

||||

|

Raw Materials

|

crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes.

|

|

|

|

||||

|

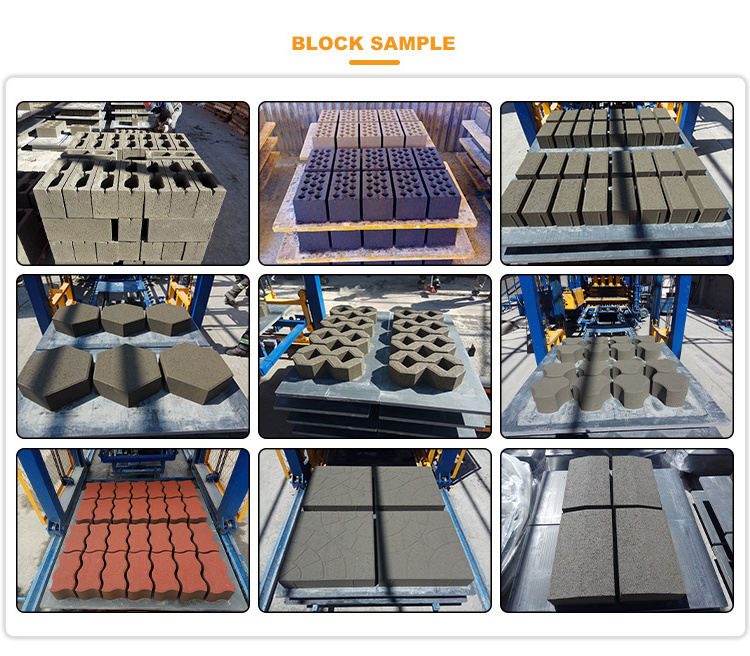

Applied Products

|

concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products,

slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

|

|

|

||||

|

Applied Fields

|

widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc.

|

|

|

|

||||

Production capacity

Details

Customer Project

Service

Hot Searches