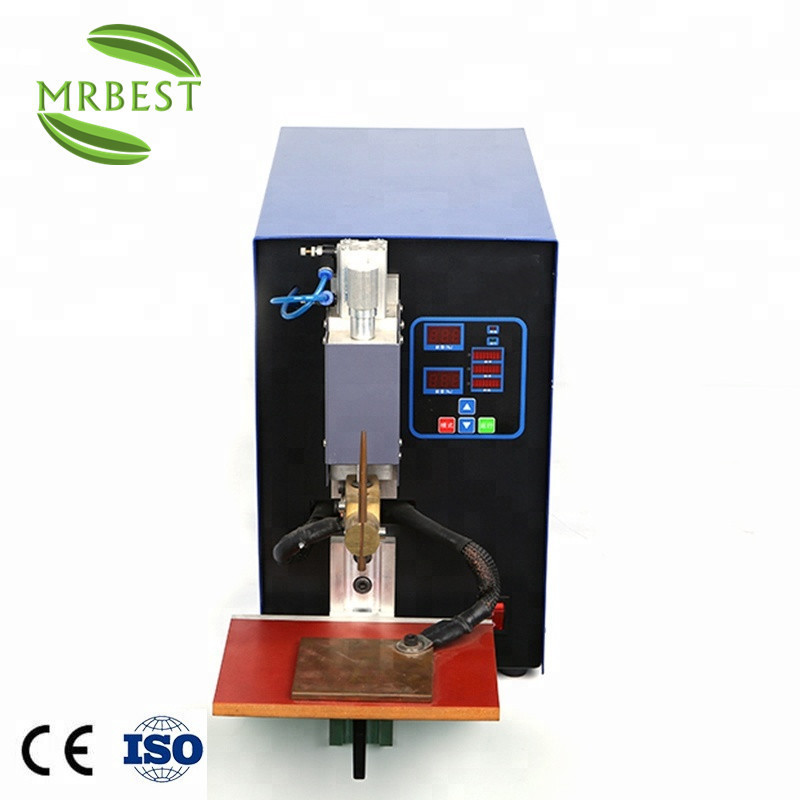

*The welding current is stable, the solder joint size is uniform, the solder joint is beautiful, the spark is small, and there is no

blackening.

* Completely overcome the low pressure and water out of the lithium battery after spot welding, is the ideal equipment for the

production of assembled batteries.

* Single-pulse, double-pulse and multi-pulse welding can be realized by microcomputer single-chip control.

* All parameters are digital settings, so the parameter adjustment is intuitive and accurate.

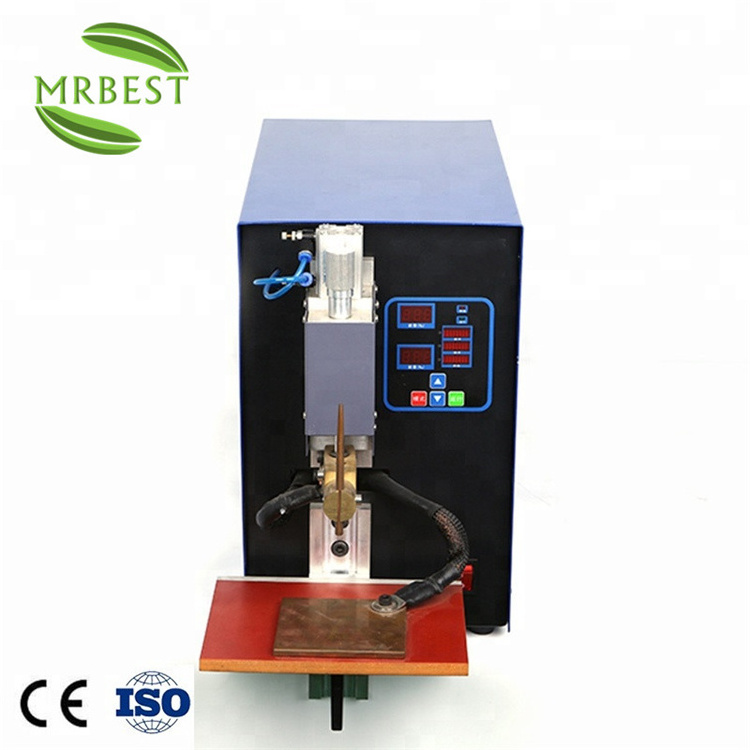

blackening.

* Completely overcome the low pressure and water out of the lithium battery after spot welding, is the ideal equipment for the

production of assembled batteries.

* Single-pulse, double-pulse and multi-pulse welding can be realized by microcomputer single-chip control.

* All parameters are digital settings, so the parameter adjustment is intuitive and accurate.