- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

clear liquid silicone rubber

-

Item:

-

RTV-1340

-

Appearance:

-

transparent/ clear

-

Mixing ratio:

-

10:1

-

Hardness:

-

40±2 Shore

-

Application:

-

for jewelry molding

-

Features:

-

High Duplication Times

-

Shelf life:

-

12 Months

-

Sample:

-

Available

-

Usage:

-

Mold making

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Rongxingda Silicone

-

Model Number:

-

RTV-1340

-

Product name:

-

clear liquid silicone rubber

-

Item:

-

RTV-1340

-

Appearance:

-

transparent/ clear

-

Mixing ratio:

-

10:1

-

Hardness:

-

40±2 Shore

-

Application:

-

for jewelry molding

-

Features:

-

High Duplication Times

-

Shelf life:

-

12 Months

-

Sample:

-

Available

-

Usage:

-

Mold making

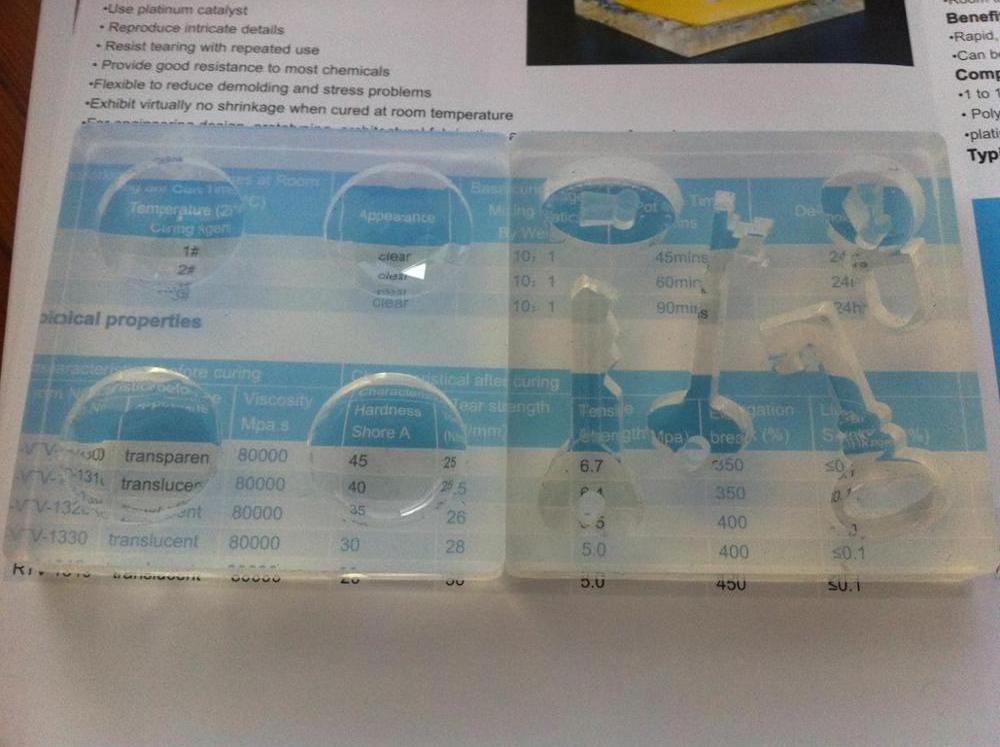

High quality safe RTV 2 custom clear liquid silicone rubber for making mold

RX silicone 1 340

Addition Cure Mold Making RTV2 Silicone Rubber

Pourable, addition-curing, two-component silicone rubber that vulcanizes at room temperature. N on-t o xic, odorless, two-component liquid silicone rubber, are two-component materials .Resistance high temp erature of 250 ℃, shrinkage rate lower than 0.1% .

Applications

Addition silicone rubbers can be applied to PU resin casting, general mold making, GRC and concrete molding, superior manual mold design, food grade molding application, rapid prototyping(urethane casting/ silicone tooling/ vacuum casting).

Features

• Almost nil shrinkage , cure at room temperature

• High Shore A hardness (approx. 40 )

• Good transparency, high tear strength

• Food grade silicone(environmental, odorless and nontoxic)

• High resistance to high temperature and aging(resist -60 to 150 ℃ )

• High chemical resistance to aggressive components of some types of resins

• O utstanding resistance to common casting resins

Important note

The platinum catalyst is in component B. A and B components may only be used together if they have the same batch number . Addition silicone rubber can react with compounds such as phosphorus, ammonia, acid, mercaptan , it will produce harmful substances.

Product data

|

Typical general characteristics |

Inspection Method |

Value |

|

Product data( uncured ) |

|

|

|

Component A |

|

|

|

color |

|

Trans parent |

|

Viscosity, dynamic at 23 ℃ , after stirring |

DIN EN ISO 3219 |

500 00± 5 000 mPa.s |

|

Density at 23℃ |

|

1. 10 g/cm³ |

|

Component B |

|

|

|

color |

|

colorless |

|

Viscosity, dynamic at 23℃ , after stirring |

|

1 00 0 ± 5 00 mPa.s |

|

Density at 23℃ |

|

1.00 g/cm³ |

|

|

|

|

|

Product data (catalyzed A+ B ) |

|

|

|

Viscosity at 23℃ |

ISO 3219 |

4500 0± 5 000 mPa.s |

|

Mix ratio(pbw) |

A:B |

10:1 |

|

Processing time(min) |

|

60 |

|

Cure time (H) |

|

8-12 |

|

|

|

|

|

Product data (cured) |

|

|

|

color |

|

transparent |

|

Density at 23℃ in water |

ISO 2781 |

1. 10 g/cm³ |

|

Hardness Shore A |

ISO 868 |

40 ± 2 |

|

Tensile strength |

ISO 37 |

> 6.0 MPa |

|

Elongation at break |

ISO 37 |

> 35 0 % |

|

Tear strength |

ASTM D 624 T |

> 16 N/mm |

|

Tear strength |

ASTM D 624 B |

> 258.8 N/mm |

|

Linear shrinkage |

|

<0.1% |

|

Pot life(min) |

|

30-40 |

Storage

The 'Best use before end' date of each batch is shown on the product label. Storage beyond the date specified on the label does not necessarily mean that the product is no longer usable. In this case however, the properties required for the intended use must be checked for quality assurance reasons.

Packing information

1. Ratio 1:1, the packing of Base A and Catalyst B

40kg/Set(Base A 20kg+ B catalyst 20kg)

400kg/Set(Base A 200kg+ B catalyst 200kg)

2. Ratio 10:1, the packing of Base A and Catalyst B

22kg/Set(Base A 20kg+ B catalyst 2kg)

220kg/Set(Base A 200kg+ B catalyst 20kg)

Safety

Components A and B of the addition-curing grade contain only constituents that over many years have proved to be neither toxic nor aggressive. Special handling precautions are therefore not required.

The information and recommendations in this publication are to the best of our knowledge reliable. However nothing herein is to be construed as a warranty or representation. Users should make their own tests to determine the applicability of such information or the suitability of any products for their own particular purposes. Statements concerning the use of the products described herein are not to be construed as recommending the infringement of any patent and no liability for infringement arising out of any such use is to be assumed.

Clear Liquid Silicone Rubber

Clear Liquid Silicone Rubber