- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

7440-50-8

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GOLD DIAMOND

-

Model Number:

-

TRPG073

-

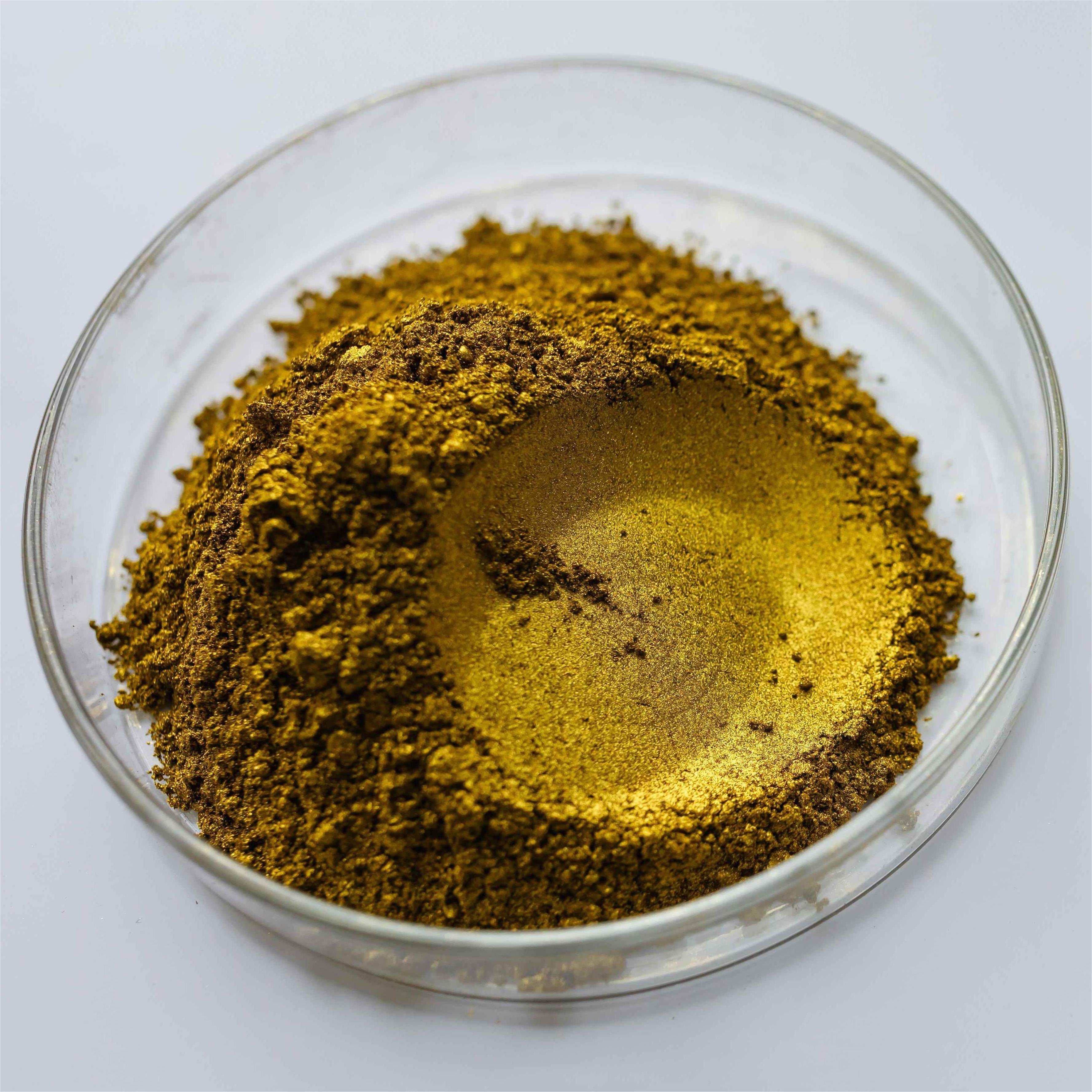

Appearance:

-

Powder

-

Color:

-

Rich pale gold

-

Particle size:

-

7-13um

-

Packing:

-

1/25/50kg

Quick Details

-

CAS No.:

-

74061030

-

Other Names:

-

Heat Resistant Bronze Powder

-

MF:

-

Cu Zn

-

EINECS No.:

-

7440-50-8

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GOLD DIAMOND

-

Model Number:

-

TRPG073

-

Appearance:

-

Powder

-

Color:

-

Rich pale gold

-

Particle size:

-

7-13um

-

Packing:

-

1/25/50kg

Heat Resistant Bronze Powder

Heat Resistant Bronze Powder or High-temperature Resistant Bronze Powder is selected for its high gloss and concentrated particle size. Through a post-processing technique, a dense layer of silicon dioxide is applied to the surface of the oil-based copper powder. This provides the copper gold powder with excellent high-temperature resistance, ensuring no discoloration even after baking at a high temperature of 250 degrees Celsius for 30 minutes.

Additionally, it exhibits good resistance to acids, alkalis, and corrosion. It is widely used in high-temperature industries such as baking paint and electrostatic spraying processes.

Which Industry We Can Apply

Screen Printing

Powder Coating

Offset Printing

Ink Industry

Textile Printing

Dip Coating

Application Industries:

Powder coating industry – No color change after baking at 230 degrees Celsius.

Water-based paints, inks, and other applications for pure water use.

Discover Our Collection Designed to Meet Business Requirements

|

Model

|

Shade

|

Average Particle Size(µm)

|

Tarnish Resistant Performance

|

|

TPG181

|

Pale gold

|

18-24µm

|

30min at 230℃

|

|

TRG182

|

Rich gold

|

|

|

|

TRPG183

|

Rich pale gold

|

|

|

|

TPG071

|

Pale gold

|

7-13µm

|

|

|

TRG072

|

Rich gold

|

|

|

|

TRPG073

|

Rich pale gold

|

|

|

|

TCP074

|

Copper Gold

|

|

|

|

TPG061

|

Pale gold

|

6-8µm

|

|

|

TRG062

|

Rich gold

|

|

|

|

TRPG063

|

Rich pale gold

|

|

|

Customizing the Perfect Bronze Powder for Your Needs

The process for personalizing Bronze powder is outlined below:

Submit your sample or specify your exact parameter needs.

Gold Diamond evaluates and devises a formula derived from the sample given.

Gold Diamond then creates a prototype based on their analysis.

Gold Diamond undertakes practical experiments with the prototype.

Finally, the prototype is dispatched to you.

Guaranteeing the High Quality of Every Barrel of Bronze Powder

Emphasizing Quality: Thorough Examination at Each Phase

Throughout the ball milling procedure, evaluate the particle size, color, and sheen hourly.

During the polishing stage, assess thebrightness, color, and particle size of the copper-gold powder in every transfer barrel, confirming uniform brightness and coloracross the batch. Mixing: Conduct sample analysis for brightness, color, and particle size for every product batch.

Storage&Packaging

Storage Instructions for Bronze Powder:

1. Store the gold powder at room temperature and away from light for two years or more. Beyond this period, the brightness of the powder may decrease and turn yellow, affecting the printing quality.

2. Gold bars solidified with resin should be stored for half a year. It is recommended that customers use them within three months, as they may become unusable due to denaturation after this period.

3. Once made into ink, the quality is best within three months. After opening, ensure the lid is securely closed. Do not exceed 30% of old ink when mixing with new ink for use.

4. Products with a particle size above 400 mesh are non-hazardous, while those below 400 mesh are flammable.

5. Long-term storage may lead to settling, but the product can be used normally after stirring.

6. The product performs best two to three months after production.

1. Store the gold powder at room temperature and away from light for two years or more. Beyond this period, the brightness of the powder may decrease and turn yellow, affecting the printing quality.

2. Gold bars solidified with resin should be stored for half a year. It is recommended that customers use them within three months, as they may become unusable due to denaturation after this period.

3. Once made into ink, the quality is best within three months. After opening, ensure the lid is securely closed. Do not exceed 30% of old ink when mixing with new ink for use.

4. Products with a particle size above 400 mesh are non-hazardous, while those below 400 mesh are flammable.

5. Long-term storage may lead to settling, but the product can be used normally after stirring.

6. The product performs best two to three months after production.

FAQ

A) How could I get a sample?

Before we received the first order, please afford the sample cost and express fee. We will return the sample cost back to you within your first order.

B) Can I buy directly form the factory?

Yes, you can purchase directly from us. This ensures you get the best price and the most direct service, streamlining your procurement process.

C) Whether you could make our brand on your products?

Yes. We can print your Logo on both the products and the packages if you can meet our MOQ.

D) Whether you could make your products by our color?

Yes, The color of products can be customized if you can meet our MOQ.

E) How to guarantee the quality of your products?

1) Strict detection during production.

2) Strict sampling inspection on products before shipment and intact product packaging ensured.

Recommend Products

Bronze Powder

Water-based Passivation Bronze Paste

Bronze Granule

Copper Powder

Hot Searches