- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Qingdao Jiaodong

-

Voltage:

-

According to customer requirements

-

Dimension(L*W*H):

-

According to the machine

-

Warranty:

-

18 months

-

Applicable Industries:

-

casting, cast steel, ceramics, Glass

-

Product name:

-

Sand mixer machine

-

Color:

-

Customized Color

-

Raw material:

-

Steel Iron

-

Technology:

-

Green Sand Casting Technology

-

Advantage:

-

Small Energy Consumption

-

Easy operation:

-

Automatic Control

-

Production ability:

-

20T/H Etc

-

Feature:

-

High Efficency

-

Usage:

-

Foundry Pieces

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

Foundry machinery

-

Warranty of core components:

-

18 months

-

Brand Name:

-

Qingdao Jiaodong

-

Voltage:

-

According to customer requirements

-

Dimension(L*W*H):

-

According to the machine

-

Warranty:

-

18 months

-

Applicable Industries:

-

casting, cast steel, ceramics, Glass

-

Product name:

-

Sand mixer machine

-

Color:

-

Customized Color

-

Raw material:

-

Steel Iron

-

Technology:

-

Green Sand Casting Technology

-

Advantage:

-

Small Energy Consumption

-

Easy operation:

-

Automatic Control

-

Production ability:

-

20T/H Etc

-

Feature:

-

High Efficency

-

Usage:

-

Foundry Pieces

|

Product number

|

Disk diameter(mm)

|

Feeding amount at one time(kg)

|

Productivity (ton/h)

|

Main motor power(kw)

|

Rotor motor power(kw)

|

Weight(kg)

|

|

GS16-30

|

1600

|

600-800

|

15-20

|

30

|

2x15

|

5000

|

|

GS20-75

|

2000

|

1000-1300

|

25-30

|

75

|

2x30

|

10000

|

|

GS22-90

|

2240

|

1300-1500

|

30-35

|

90

|

2x37

|

12000

|

|

GS22-110

|

2240

|

1500-1800

|

35-40

|

110

|

2x37

|

12500

|

|

GS25-132

|

2500

|

2000-2500

|

50-60

|

132

|

2x45

|

16500

|

|

GS26-160

|

2600

|

2500-3000

|

60-70

|

160

|

2x45

|

18000

|

|

GS28-200

|

2850

|

3600-4200

|

80-100

|

200

|

2x55

|

22500

|

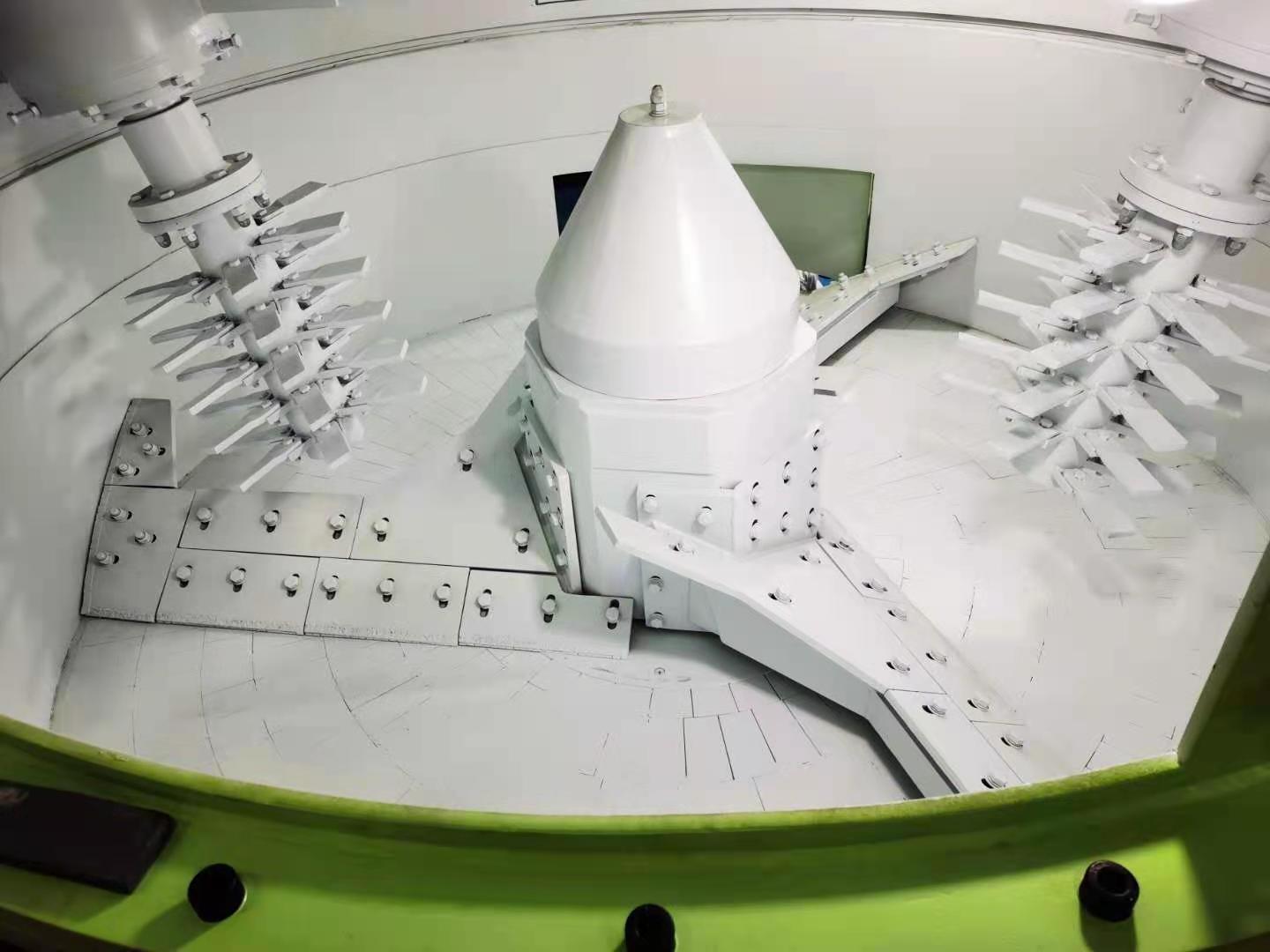

There are four types of sand mixers produced by our company

1. According to the standard JB / T 505-96 general technical conditions for clay sand mixer of Ministry of machinery industry , the new type of sand mixer is designed, in which S1110, s1120c and s1122 are roller type sand mixer; S1320c, s1322, etc. are roller rotor sand mixers. The main parameters of these sand mixers are disc diameter (1 / 100 of mm).

2. S14 series rotor sand mixer

3. GS series high efficiency rotor sand mixer

Rotor sand mixer is a new type of sand mixer designed according to JB / T 7457-96 specification of rotor sand mixer. The machine is designed with three national patents (cn87212671.3, cn91221796.0, cn92245442.6). Its working mechanism is an original creation at home and abroad. This series of sand mixers are designed with disc diameter (1 / 100 of mm) as the main parameter. The rolling wheel mixer produced by our company adopts new structure, new material and excellent performance, such as spring pressure regulating mixing rolling mechanism, diabase cast stone liner, scraper surfacing tungsten carbide alloy, centralized forced lubrication of main transmission device, etc., which are highly praised by users. When mixing other types of sand, the above parameters should be adjusted according to different process requirements.

1. performance description

GS series machine is a high efficient sand mixer designed by our factory with reference to the similar products around the world. Over the years, we have constantly improved to make the driving and working mechanism more reliable and reasonable.

Features of main machine parts :

① The reducers geared up transmission by large modulus alloy steel with firm tooth surface for reliability and long service life. Each pair of gears have observed window to check on the lubricating gears. A magnetic oil plug is arranged under reducer bottom , so as to catch the metal chips in some lubricant oil and reduce the wear on the gears and bearings.

All the gears and bearings in the reducer can work in a better lubrication. Electric contact thermometer is fixed outside reducer on overheating oil temperatures.

2. Selection of main purchased parts and materials

①. The body is made of δ16mm steel plate, and the inner cylinder is turned;

②. δ6-10mm stainless steel inner ring;

③. Ceramic backing plate, spherical head;

④. Welding-on YG8 cemented carbide for scraper and rotor rake teeth

⑤. The rotor mechanism adopts Japanese NSK bearing;

⑥. The rotor adopts Becher oil pump to ensure the reliable operation of the rotor bearing;

1. According to the standard JB / T 505-96 general technical conditions for clay sand mixer of Ministry of machinery industry , the new type of sand mixer is designed, in which S1110, s1120c and s1122 are roller type sand mixer; S1320c, s1322, etc. are roller rotor sand mixers. The main parameters of these sand mixers are disc diameter (1 / 100 of mm).

2. S14 series rotor sand mixer

3. GS series high efficiency rotor sand mixer

Rotor sand mixer is a new type of sand mixer designed according to JB / T 7457-96 specification of rotor sand mixer. The machine is designed with three national patents (cn87212671.3, cn91221796.0, cn92245442.6). Its working mechanism is an original creation at home and abroad. This series of sand mixers are designed with disc diameter (1 / 100 of mm) as the main parameter. The rolling wheel mixer produced by our company adopts new structure, new material and excellent performance, such as spring pressure regulating mixing rolling mechanism, diabase cast stone liner, scraper surfacing tungsten carbide alloy, centralized forced lubrication of main transmission device, etc., which are highly praised by users. When mixing other types of sand, the above parameters should be adjusted according to different process requirements.

1. performance description

GS series machine is a high efficient sand mixer designed by our factory with reference to the similar products around the world. Over the years, we have constantly improved to make the driving and working mechanism more reliable and reasonable.

The working principle is that the low-speeding scraper blades pushes up the materials circulation inside basin. Not only

high-speed rotor impact force on the materials, but also cut on the materials in coordination with the scraper, so as to bump promptly and crash strongly among sand particles, therefore speed up sand mixing in good quality.

high-speed rotor impact force on the materials, but also cut on the materials in coordination with the scraper, so as to bump promptly and crash strongly among sand particles, therefore speed up sand mixing in good quality.

This machine have simple structure, easy operation and maintenance. The transmission and sand mixing have high reliability, large installed power, huge amount of feeding, high productivity.

Compared with others at home and abroad, the rotor mixer have distinct advantages as larger diameter, wide range of activation. Optimized angles on rotor blade and scraper, stir the materials strongly and evenly. It is an ideal sand mixer with advanced parameters, reasonable structure and reliable application.

The machine is mainly composed of reducer, column, rotor, body, discharge door, lubrication system, scraper device and other structures.

The output shaft of the reducer connected the column with chain coupling, and the main shaft drives the crosshead rotating anticlockwise, so that the scraper device drives the molding sands in circulation on machine basin.

Two sets of rotors are symmetrically installed on the shroud, driven by motor through the triangle belt, makes rotor rotating in accordance with the blades impacting, cutting and scraping against the molding sands.

The reducer installed on the foundation, and the chain coupling disconnected in heavy repair, it can be pulled out horizontally for maintenance.

A cleaning door is arranged on the enclosure for better machine maintenances. A security switch is also attatched for the safety maintenance and operations.

Compared with others at home and abroad, the rotor mixer have distinct advantages as larger diameter, wide range of activation. Optimized angles on rotor blade and scraper, stir the materials strongly and evenly. It is an ideal sand mixer with advanced parameters, reasonable structure and reliable application.

The machine is mainly composed of reducer, column, rotor, body, discharge door, lubrication system, scraper device and other structures.

The output shaft of the reducer connected the column with chain coupling, and the main shaft drives the crosshead rotating anticlockwise, so that the scraper device drives the molding sands in circulation on machine basin.

Two sets of rotors are symmetrically installed on the shroud, driven by motor through the triangle belt, makes rotor rotating in accordance with the blades impacting, cutting and scraping against the molding sands.

The reducer installed on the foundation, and the chain coupling disconnected in heavy repair, it can be pulled out horizontally for maintenance.

A cleaning door is arranged on the enclosure for better machine maintenances. A security switch is also attatched for the safety maintenance and operations.

Features of main machine parts :

① The reducers geared up transmission by large modulus alloy steel with firm tooth surface for reliability and long service life. Each pair of gears have observed window to check on the lubricating gears. A magnetic oil plug is arranged under reducer bottom , so as to catch the metal chips in some lubricant oil and reduce the wear on the gears and bearings.

All the gears and bearings in the reducer can work in a better lubrication. Electric contact thermometer is fixed outside reducer on overheating oil temperatures.

②The chassis fixed on the column, which have transmission connection on reducer and scraper all around the disc up and down. The column bearings apply to universial lithium grease.

③ The bearings of the rotor mechanism are lubricated with lithium base grease, and the rotor blades welding on YG8 hard alloys. The bearings of rotor lubricated regularly in certain amount on dry lubricant pump to ensure the rotor bearings with long life.

③ The bearings of the rotor mechanism are lubricated with lithium base grease, and the rotor blades welding on YG8 hard alloys. The bearings of rotor lubricated regularly in certain amount on dry lubricant pump to ensure the rotor bearings with long life.

④ Except the cleaning door, 8mm thick stainless steel plate is also fixed to the inner ring of the machine basin. The ceramic bottom lining plate have high flatness, smaller scraper clearance and even sand mixing; a new type filling angle is designated around the machine basin, to solve the problem of sand sticking and cleaning. The side unloading door shake sands out fast and proper.

⑤ The optimized combination of scraper angle and blade angle strengthens the movement of materials up and down. The large diameter rotor with high speeding enlarges activated ranges. All materials inside the basin activate sand mixing evenly.

⑥.The filling Sequence is sands, water and then powders. This advanced technology reduced materials loss and avoid clays formation , stabilize molding sand performance.

⑤ The optimized combination of scraper angle and blade angle strengthens the movement of materials up and down. The large diameter rotor with high speeding enlarges activated ranges. All materials inside the basin activate sand mixing evenly.

⑥.The filling Sequence is sands, water and then powders. This advanced technology reduced materials loss and avoid clays formation , stabilize molding sand performance.

2. Selection of main purchased parts and materials

①. The body is made of δ16mm steel plate, and the inner cylinder is turned;

②. δ6-10mm stainless steel inner ring;

③. Ceramic backing plate, spherical head;

④. Welding-on YG8 cemented carbide for scraper and rotor rake teeth

⑤. The rotor mechanism adopts Japanese NSK bearing;

⑥. The rotor adopts Becher oil pump to ensure the reliable operation of the rotor bearing;

Hot Searches