- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

420 mm

-

Width of Working Table (mm):

-

85 mm

-

Dimension:

-

3800*1600*2450mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BLMA

-

Year:

-

2022

-

Weight (KG):

-

6800

-

Motor Power (kw):

-

7.5 kw

-

Usage:

-

Metal Sheet Bending

-

Keyword:

-

press brake machine hydraulic

-

Voltage:

-

220V/380V/415V/440V/customized

-

Certification:

-

ISO 9001:2000

-

After-sales Service Provided:

-

Free spare parts

-

Nominal Pressure (kN):

-

1000 kN

Quick Details

-

Machine Type:

-

Torsion Bar

-

Length of Working Table (mm):

-

3200

-

Slider Stroke (mm):

-

200 mm

-

Throat Depth (mm):

-

420 mm

-

Width of Working Table (mm):

-

85 mm

-

Dimension:

-

3800*1600*2450mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BLMA

-

Year:

-

2022

-

Weight (KG):

-

6800

-

Motor Power (kw):

-

7.5 kw

-

Usage:

-

Metal Sheet Bending

-

Keyword:

-

press brake machine hydraulic

-

Voltage:

-

220V/380V/415V/440V/customized

-

Certification:

-

ISO 9001:2000

-

After-sales Service Provided:

-

Free spare parts

-

Nominal Pressure (kN):

-

1000 kN

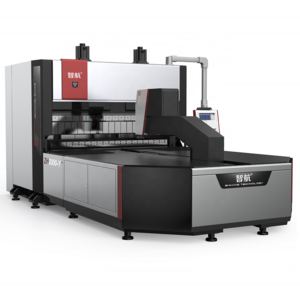

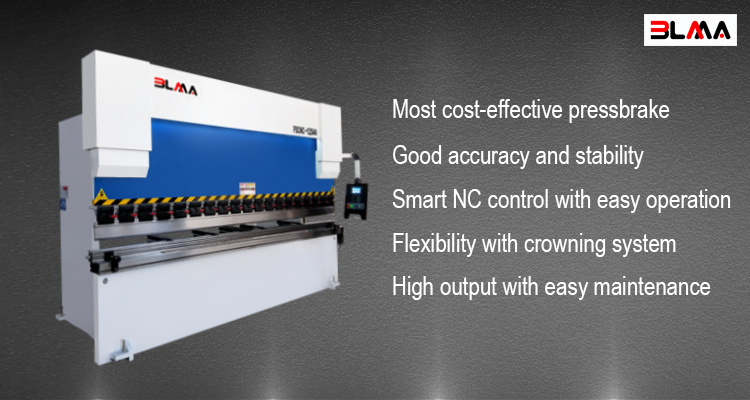

Main Features

The multi-step programming function can realize the automatic operation and continuous positioning of the multi-step program,and realize the automatic and precise adjustment of the back gauge and the position of the slider.

The bending counting function can display the processing quantity in real time, and can also memorize the position of the back gauge slider and the current program and parameters when the power is off.

High-speed ball screw and linear guide are used to ensure the positioning accuracy of the back gauge.

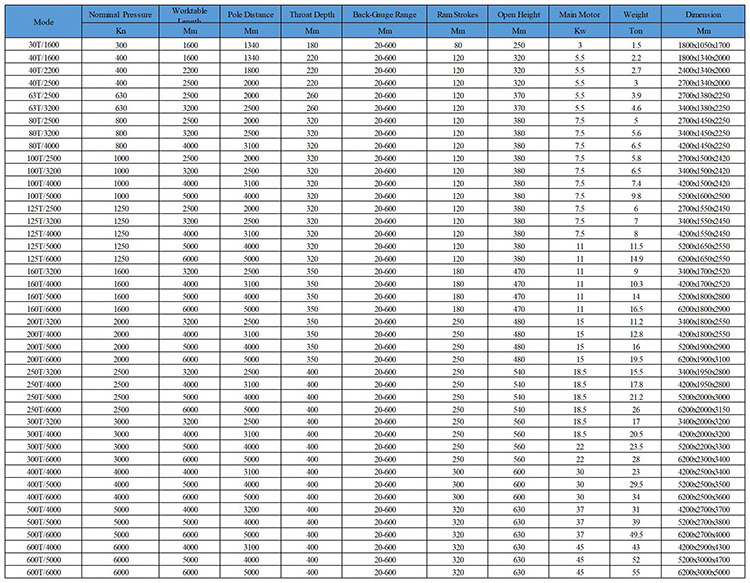

Product Paramenters

Detailed Description

E300 CNC Controller

Schneider Electrics

Shilin Inverter

Simens Motor

Sunny/First Pump

Rexroth Valves

Oil Cylinder With NOK Seals

EMB Connector

Fast Clamping System

Movable Front Support

Stop Finger With Height Adjustment (Optional)

Motorized Crowing Table (Optional)

DSP Laser Safty (Optional)

Motorized Stop Finger (Optional)

Bending sample

Our services

Pre-service

1.We will help you confirm the model of our machine according to your offered pipe information.

2.You are very welcome to see our machine how to work in the factory before you place an order

with us.

with us.

Aftersales-service:

1.

Our machine is easy to use. Operation manual and teaching video will be sent out with machine.

We also offer free training in our factory, the following is our training contents:

Detailed function of our machine, 1 hour;

NC control using, 0.5 hour;

Tooling installation and adjustment, 0.5-1 hours;

Maintenance and repair, 0.5-1 hours;

Real operation according client products, 1-2 hours.

During the training period,we offer free pick-up,hotel and food.

2. We guarantee machine quality for 13 months, during this period, if spare parts of the machine are not man-made damage, we can send the component to the customer by DHL, TNT freely.

3.Our factory provide the service for the customer forever, if the customer need operation help,we

provide 24 hours on-line reply service.

provide 24 hours on-line reply service.

Hot Searches