- Product Details

- {{item.text}}

Quick Details

-

Power:

-

60kw

-

Dimension(L*W*H):

-

3030*3110*3350mm

-

Weight:

-

3500 kg

-

Marketing Type:

-

New Product 2023

-

Finished Products:

-

Egg Tray Egg Carton

-

Molds:

-

Plastics/Aluminium

-

Product name:

-

Egg Tray Machine

-

Application:

-

Chicken Farm/Packing Industry

-

Raw material:

-

Various types of waste paper

-

Use:

-

egg tray,bottle tray,fruit tray,egg box

-

Keyword:

-

Small egg tray machine

-

Function:

-

Making egg trays, shoe trays, coffee trays, etc

Quick Details

-

Production Capacity:

-

1000-7000psc/hour

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220/380/440

-

Power:

-

60kw

-

Dimension(L*W*H):

-

3030*3110*3350mm

-

Weight:

-

3500 kg

-

Marketing Type:

-

New Product 2023

-

Finished Products:

-

Egg Tray Egg Carton

-

Molds:

-

Plastics/Aluminium

-

Product name:

-

Egg Tray Machine

-

Application:

-

Chicken Farm/Packing Industry

-

Raw material:

-

Various types of waste paper

-

Use:

-

egg tray,bottle tray,fruit tray,egg box

-

Keyword:

-

Small egg tray machine

-

Function:

-

Making egg trays, shoe trays, coffee trays, etc

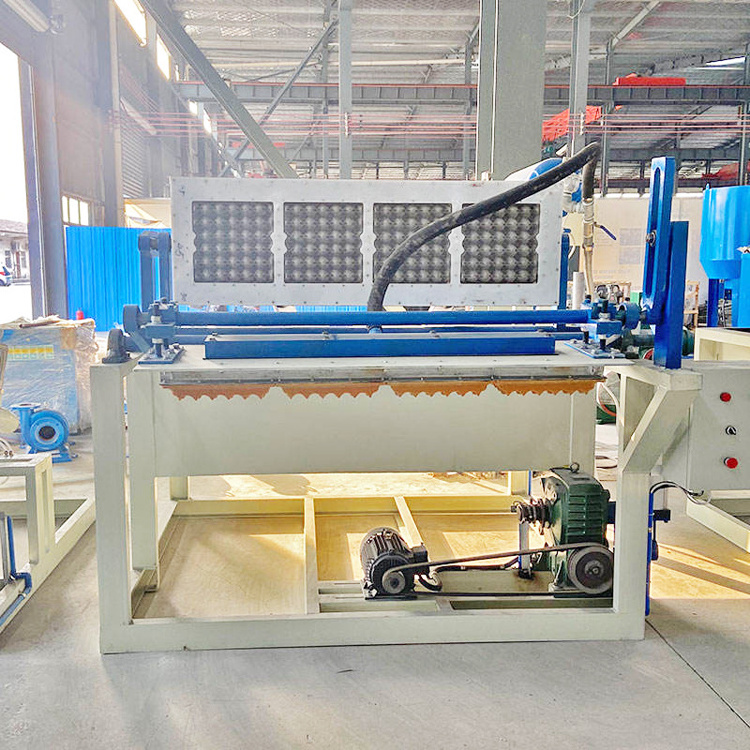

Product Overview

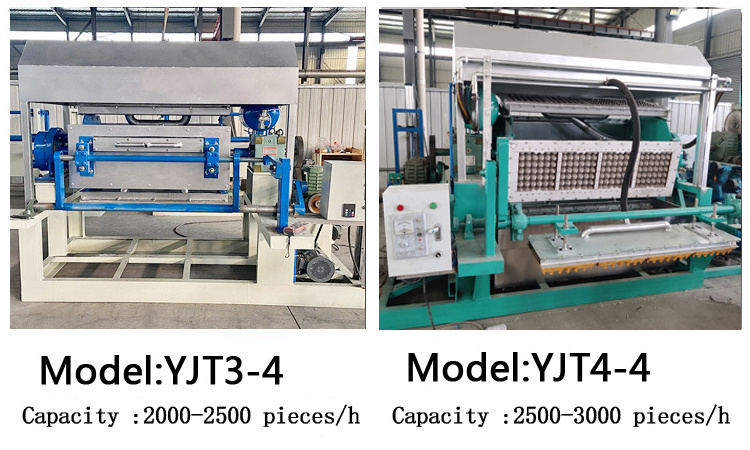

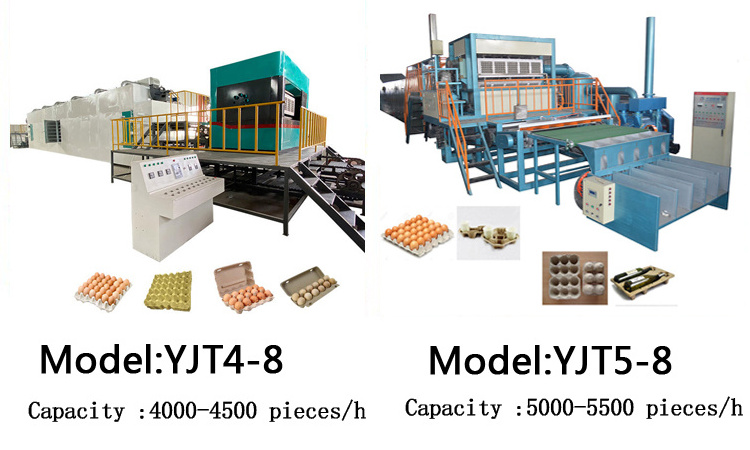

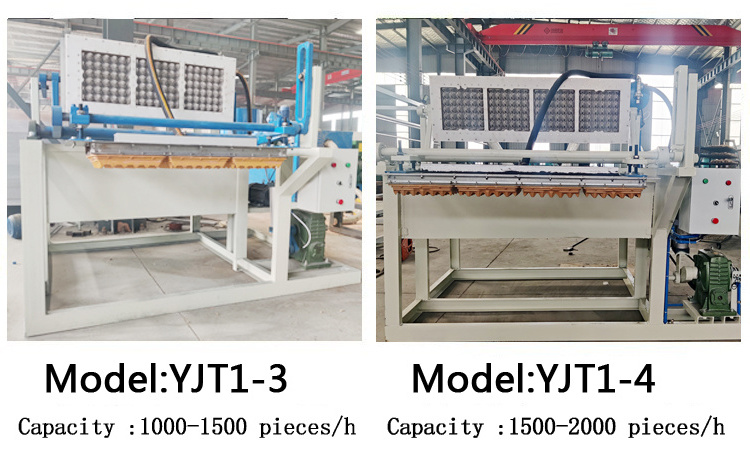

We offers seven models of egg tray making machines. All of them can work automatically. According to capacity, 7 models can be divided into small-scale type, medium-scale type and large-scale type. The dryer is also an important factor. The dryer will influence the production time. The brick dryer and metal dryer will shorten the drying time largely. When you select an appropriate line, the efficiency and waste utilization rate can be greatly improved.

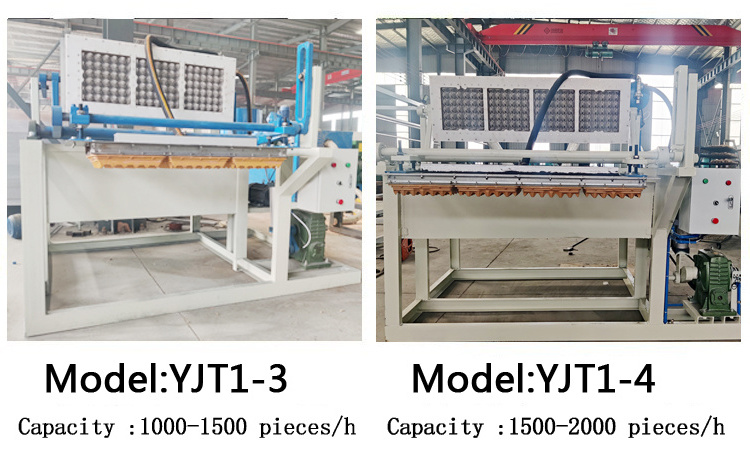

PRODUCT SPECIFICATIONS

|

Model

|

YJT

1-3

|

YJT

1-4

|

YJT

3-4

|

YJT

4-4

|

YJT

4-8

|

YJT

5-8

|

YJT

6-8

|

|

capacity

(pieces/h)

|

1000-1500

|

1500-2000

|

2000-2500

|

2500-3000

|

4000-4500

|

5000-5500

|

6000-7000

|

|

Forming Mould Quantity

|

3

|

4

|

12

|

16

|

32

|

40

|

48

|

|

Total Power

|

33

|

42

|

54

|

82

|

127

|

160

|

223

|

|

Electricity Consumption (kw/h)

|

23

|

29

|

38

|

58

|

89

|

112

|

156

|

|

Labor Force

|

3-5

|

3-5

|

4-5

|

4-5

|

5-6

|

5-6

|

5-6

|

|

Workshop Area(m²)

|

80

|

80

|

100

|

100

|

200

|

220

|

300

|

|

water consumption (kg/h)

|

200-300

|

300-400

|

400-500

|

500-600

|

800-900

|

1000-1100

|

1200-1300

|

|

Paper consumption(kg/h)

|

100-150

|

150-200

|

200-250

|

250-300

|

400-450

|

500-550

|

600-650

|

|

Coal Consumption(kg/h)

|

50

|

60

|

83

|

104

|

160

|

185

|

208

|

|

Natural Gas Consumption (m3/h)

|

22-32

|

26-36

|

37-47

|

46-56

|

67-77

|

82-92

|

92-103

|

Small-scale Egg Tray Machine in China

Model: YJT1-3 and YJT1-4

Capacity: 800-1500 pieces/h

Recommended Dryer: natural drying under the sun

Finished Product Display

Replacing the equipment with different molds can produce different products

Many aspects in egg trays can be customized, including shape, color, weight and features. Leave your detailed requirement to us.

Item Option

Shape: Egg tray, egg carton, shoe tray, bottle tray, coffee cup tray, seedling tray, fruit tray, etc

Holes: The number of holes can be customized. We provide standard egg trays (18 holes, 20 holes, 24 holes and 30 holes) and egg cartons (6 holes, 12 holes and 18 holes)

Additive: Color additive, water repellent

Weight: The weight of paper trays can be customized according to customer’ need. The standard weight is 70-100g

.

Egg tray finished product display

Working Principle and Process

What is Egg Tray Production Process

1:Paper Pulp Making Process

Put all waste papers into hydraulic pulper and slurry pump. After mixed with water, waste paper will be turned into slurry. Normally, components of waste will partly influence final quality of trays.

2:Egg Tray Molding Process

Due to negative pressure and vacuum absorption, the slurry will be turned into paper tray in the egg tray forming mould. Air compressor and vacuum pump will assist this work to be done well.

3:Egg Tray Drying Process

We provide three kinds of drying systems. The requirement for budget, land and local condition is different. When you wanna get the best plan, consult us to get detailed information

Different drying methods for different output configurations

Natural Drying:

Advantages:Economical and practical, low investment and fast results.

Disadvantages:More weather-dependent, suitable for use in dry and hot weather conditions.

Brick Kiln Drying

Advantages:High output, fast drying efficiency, moderate investment.

Disadvantages:Large footprint, long construction time, need to have a technician on site to guide the construction.

Metal Dryer line

Advantages:High output, high drying efficiency, moderate floor space, easy and quick installation,High degree of automation.

Disadvantages:Large investment

If you are not sure which one is right for you, you can contact us and we will recommend the right configuration for you.

Product Acessories

Package and shiping

Company profile

Yijiatong machinery equipment co.,ltd.supplies all kinds of egg dish machine,egg dish production line,egg dish pro-duction

complete sets of equipment and technology .

complete sets of equipment and technology .

We have exported more than 100countries like Côte d'Ivoire,Zambia,Egypt,Iraq,Brazil,Russia, India etc.We can customize models that are suitable for customers based on their actual needs the main products are:all kinds of large, medium and small egg plate machine,production line,complete equipment pulp-forming machine,packaging machine,setting machine,all kinds of molds,egg plate products and all kinds of egg plate accessories,Deeply trusted by domestic and foreign users.

FAQ

1:What Fuels Can be Used in Egg Tray Production Line?

The most common fuels are coal, biomass waste, natural gas and diesel.

2:How Much Expense Required for Full Set-up When Imported from China?

Take the following three parts into consideration, including machine cost, delivery charges, and

installation charges.

3:Are you a manufacturer or trader?

we are a manufacture special on pulp moulding mould with many years experience.

4:What is your production cycle?

Usually the delivery time is about 7 - 15days after the payment confirmed. It is also

depend on the machines. If need to customize the machine as your requirement, the

producing time is longer.

5:What kinds of mould do you produce?

We produce all kinds of pulping mold, such as egg tray molds,egg box molds,fruit tray

molds,coffee cup tray molds,wine tray molds, industrial package mold etc.

6:How should I choose the model?

You could tell us your request for select our existing model or newly designed mould. Just

30 holes egg tray pulp mould, we have more than 100 types. you can send us pulping

products (such as egg tray/egg box) ,we can design the mould.

7:The guarantee

All the equipment ordered from us will provide one year guarantee from the delivery date.

If there is any wearing part that is broken within the warranty period and it isn't caused by

improperly operation,then we would offer the new parts for free.

8:How to install the mold?

We have professional technician guidance to assist you with installation.

9:What is your payment term?

After confirming the PI, you need pay 30% T/T deposit to start production, 70% balance

before shipment.

Hot Searches