- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

<1%

-

CrO Content (%):

-

none

-

SiC Content (%):

-

none

-

Place of Origin:

-

Jiangsu, China

-

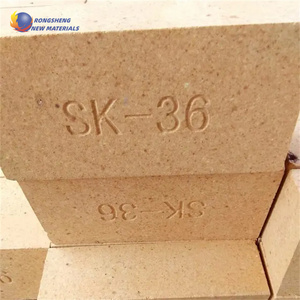

Model Number:

-

SK32/34/36

-

Brand Name:

-

BRICKMAC

-

model:

-

SK36

-

ALUMINA CONTENT:

-

>50%

-

MAX TEMPERATURE:

-

1450°C

-

Density:

-

2.25-2.35 g/cm³

-

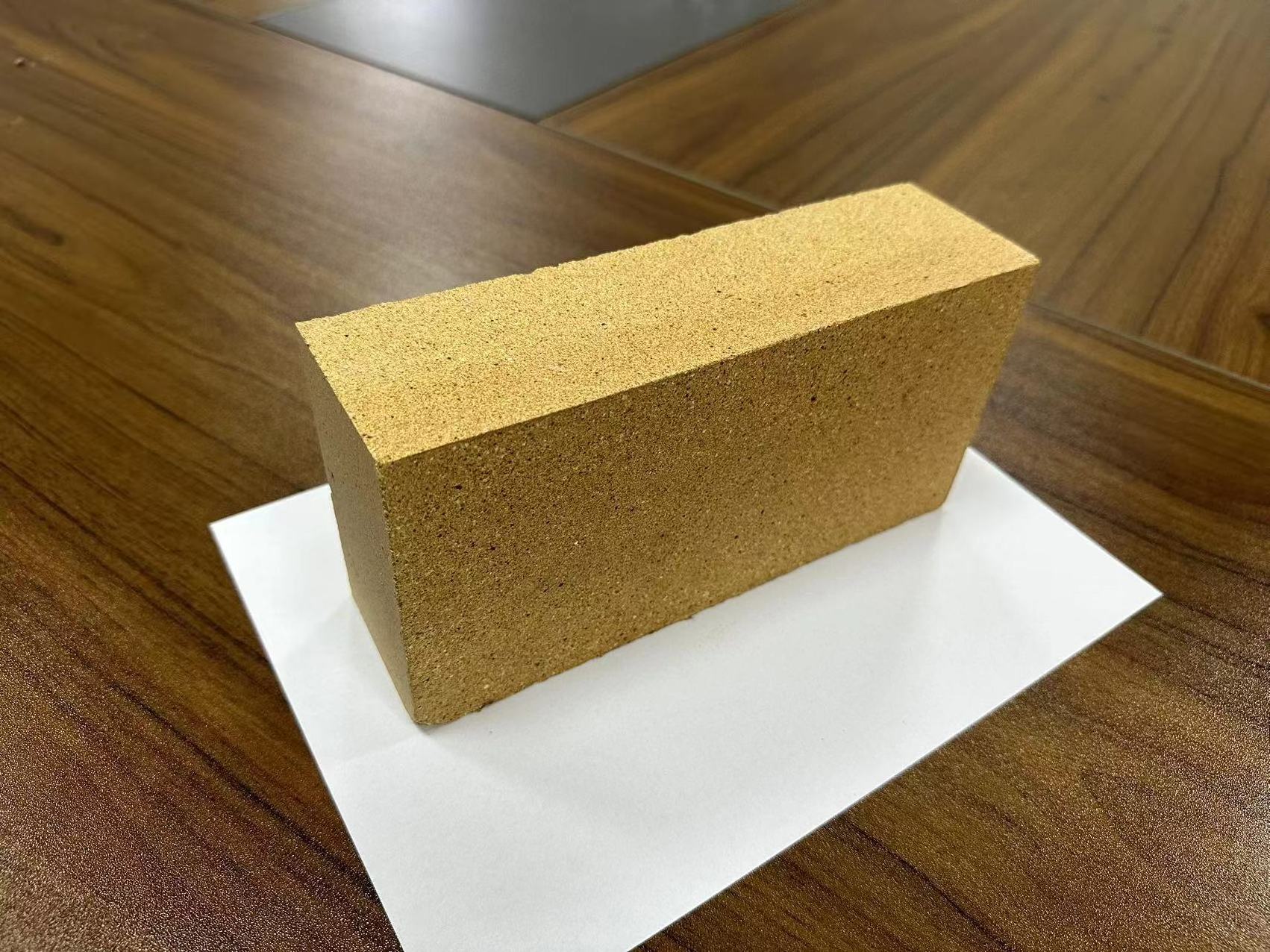

Size:

-

230 x 114 x 65 mm

Quick Details

-

SiO2 Content (%):

-

< 5%

-

Al2O3 Content (%):

-

35~55%

-

MgO Content (%):

-

<1%

-

CaO Content (%):

-

<1%

-

CrO Content (%):

-

none

-

SiC Content (%):

-

none

-

Place of Origin:

-

Jiangsu, China

-

Model Number:

-

SK32/34/36

-

Brand Name:

-

BRICKMAC

-

model:

-

SK36

-

ALUMINA CONTENT:

-

>50%

-

MAX TEMPERATURE:

-

1450°C

-

Density:

-

2.25-2.35 g/cm³

-

Size:

-

230 x 114 x 65 mm

Product Overview

INDUSTRIAL FIRE BRICKS

Our high alumina bricks are produced with selected bauxite chamotte by advanced process and strict quality control. It is an aluminum silicate refractory product with aluminum oxide (Al2O3) content higher than 48%. The main component of this refractory brick is AL2O3. It features excellent high temperature mechanics and chemical corrosion resistance.

According to their Alumina content, they fall into two main

categories, all of which exhibit excellent strength and endurance:

categories, all of which exhibit excellent strength and endurance:

* Fire clay bricks (Alumina content < 45%): low thermal conductivity, excellent thermal insulation performance, high resistance to thermal shock, easy to install and can be used in many applications.

* High Alumina bricks (Alumina content >50%): high temperature performance, high corrosion and wear resistance, high bulk density.

Scope of application:

1. Furnaces of metallurgy industry, heat treatment furnace.

2. Furnaces of chemical industry and construction industry.

3. Furnace of incineration of garbage, recirculation fluidized bed furnace.

* High Alumina bricks (Alumina content >50%): high temperature performance, high corrosion and wear resistance, high bulk density.

Scope of application:

1. Furnaces of metallurgy industry, heat treatment furnace.

2. Furnaces of chemical industry and construction industry.

3. Furnace of incineration of garbage, recirculation fluidized bed furnace.

FEATURES AT A GLANCE

High density and high alumina content, which lead to low thermal conductivity and good thermal insulation performance

High load softening temperature

It has high AL2O3 content , less impurities and less fusible glass bodies , so the load softening temperature is high.

high alumina refractory brick is close to natural refractory materials, it can resist the erosion of acidic slag and alkaline.

PRODUCT SPECIFICATIONS

|

GRADE

|

SK-32

|

SK-34

|

SK-36

|

SK-38

|

SK-40

|

|

AL2O3 %

|

48

|

55

|

65

|

75

|

80

|

|

FE2O3 %

|

≤3

|

≤3

|

≤1.8

|

≤1.6

|

≤1.5

|

|

Refractoriness ℃

|

≥1350

|

≥1400

|

≥1450

|

≥1500

|

≥1550

|

|

Bulk density g/cm3

|

2.15 - 2.25

|

2.25 - 2.35

|

2.35 - 2.45

|

2.45 - 2.65

|

2.65 - 2.75

|

|

Porosity %

|

≤24

|

≤23

|

≤23

|

≤22

|

≤21

|

|

Strength Mpa

|

≥35

|

≥40

|

≥45

|

≥55

|

≥60

|

|

|

|

|

|

|

|

Manufacturing Technique

Hot Searches