- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Voltage:

-

28kw

-

Dimension(L*W*H):

-

4800*3300*1930mm

-

Weight:

-

1600 kg, 5500kg

-

Machine Model:

-

DBWSFQ200

-

Jumbo roll with:

-

1600mm

-

Max.Dia of materiai:

-

1200mm

-

Max.Dia of rewind:

-

1000mm

-

Slitting speed:

-

10-300/min

-

Min.Width of rewind:

-

100mm

-

Power:

-

28kw

-

Overall dimension:

-

4800*3300*1930

Quick Details

-

Type:

-

Paper Cutting Machine

-

Production Capacity:

-

300 m/min

-

Max. workable width:

-

1300mm

-

Place of Origin:

-

Zhejiang, China

-

Voltage:

-

28kw

-

Dimension(L*W*H):

-

4800*3300*1930mm

-

Weight:

-

1600 kg, 5500kg

-

Machine Model:

-

DBWSFQ200

-

Jumbo roll with:

-

1600mm

-

Max.Dia of materiai:

-

1200mm

-

Max.Dia of rewind:

-

1000mm

-

Slitting speed:

-

10-300/min

-

Min.Width of rewind:

-

100mm

-

Power:

-

28kw

-

Overall dimension:

-

4800*3300*1930

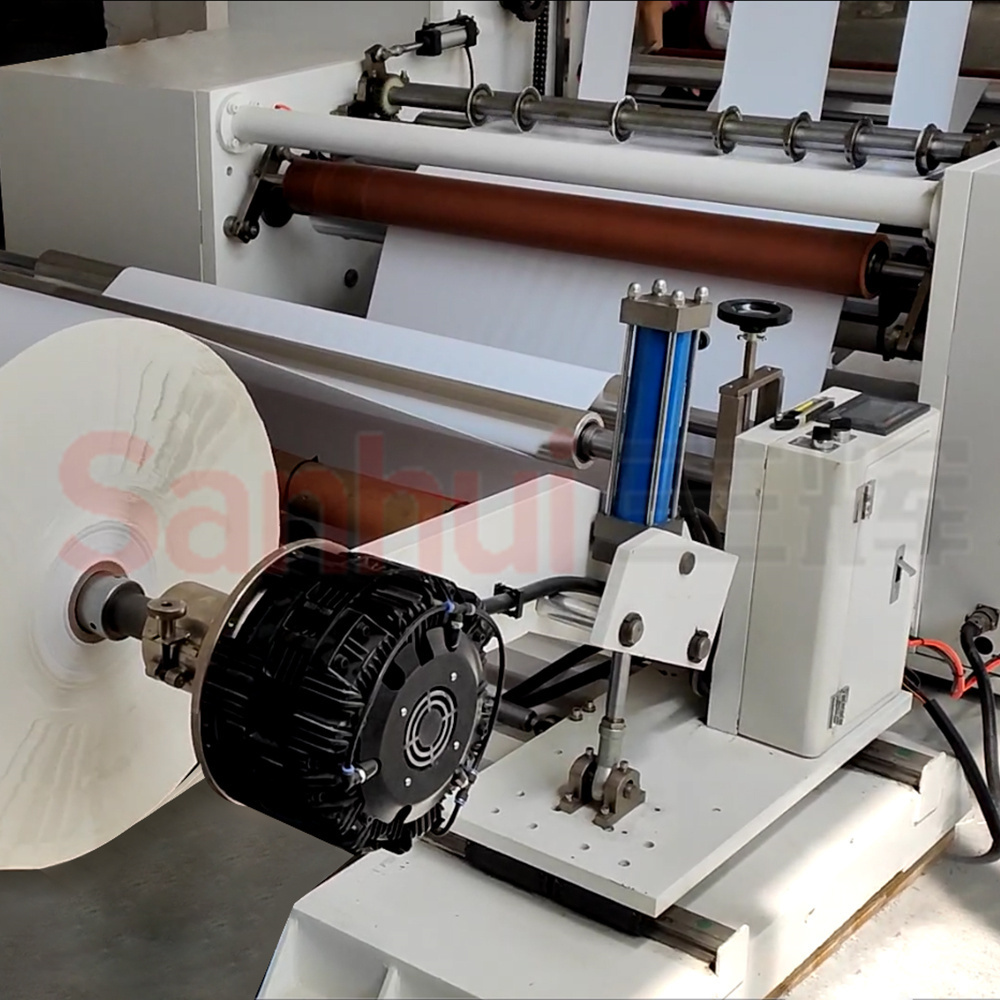

Products Description

Main Features

1. The whole machine frame is made of iron plate, with extremely high precision and stability.

2. Main motor adopts single-phase asynchronous motor.

3. PhotoelectricEPC system.

4. Inverter : Delta

5. Automatic constant tension of unwinding and rewindingby magnetic powder brake and clutch.

6. Rewinding and unwinding adopts air shaft.

7. Guide roller is plated with hard chromium, which makes the guide roller hard, wear-resistant, mild and corrosion-resistant

8. Electrical equipment

9. The standard machine equipped with 1 set(10 pcs)circular knives, razor knife is optional.

10. The machine has the auto functions like automatic counting meter, emergency stop, alarm etc.

2. Main motor adopts single-phase asynchronous motor.

3. PhotoelectricEPC system.

4. Inverter : Delta

5. Automatic constant tension of unwinding and rewindingby magnetic powder brake and clutch.

6. Rewinding and unwinding adopts air shaft.

7. Guide roller is plated with hard chromium, which makes the guide roller hard, wear-resistant, mild and corrosion-resistant

8. Electrical equipment

9. The standard machine equipped with 1 set(10 pcs)circular knives, razor knife is optional.

10. The machine has the auto functions like automatic counting meter, emergency stop, alarm etc.

|

Model

|

SHZX-W

|

SHZX-W

|

SHZX-W

|

|

Jumbo roll with

|

1300mm

|

1600mm

|

1800mm

|

|

Max.Dia of materiai

|

1200mm

|

1200mm

|

1200mm

|

|

Max.Dia of rewind

|

1000mm

|

1000mm

|

1000mm

|

|

Slitting speed

|

10-300/min

|

10-300/min

|

10-300/min

|

|

Tolerance of EPC

|

≤0.1mm

|

≤0.1mm

|

≤0.1mm

|

|

Min.Width of rewind

|

100mm

|

100mm

|

100mm

|

|

Power

|

22kw

|

28kw

|

32kw

|

|

Weight

|

4800kg

|

5500kg

|

6000kg

|

|

Overall dimension

|

4800×2900×1930mm

|

4800×3300×1930mm

|

4800×3600×1930mm

|

Product Applicable

The machine is suitable for slitting rewind kinds of material jumbo rolls according customized size, material including: all kinds of film ,PVC shrink film,adhesive label, aluminum laminated film, kinds of paper, kraft paper , etc.

Our Company

FAQ

FAQ

Q: What's your delivery date?

A: Usually finish the production within 30days after your 30% advanced payment, actually need to check according our stock &

production plan.

Q: Terms of payment?

A: We accept T/T, 30% in advance and 70% balanced against B/L copy. We accept L/C at sight. We accept Cash.

Q: How many days will you finish installing ?

A: We will finish installation and training within 15days.

Q: How long is your machine's warranty period?

A: All our machine have one year guarantee, starting from finished installation.

Q: How could we do after one year warranty period?

A: We also can do service for you, however, if require overseas service, you need pay salary to our technician 100USD/day.

Q: How could we do if the parts broken within warranty?

A: We would express the free replacement parts during the warranty date.

Q: How many worker do we need running those machines?

A: For flexo printing, slitting, die-cutting machine, only need one person for each.

Q: What should we charge for your engineer?

A: You should charge for the cost of our engineer's visa , air tickets, hotel, food ,and also their salary 100USD one day per

person.

A: Usually finish the production within 30days after your 30% advanced payment, actually need to check according our stock &

production plan.

Q: Terms of payment?

A: We accept T/T, 30% in advance and 70% balanced against B/L copy. We accept L/C at sight. We accept Cash.

Q: How many days will you finish installing ?

A: We will finish installation and training within 15days.

Q: How long is your machine's warranty period?

A: All our machine have one year guarantee, starting from finished installation.

Q: How could we do after one year warranty period?

A: We also can do service for you, however, if require overseas service, you need pay salary to our technician 100USD/day.

Q: How could we do if the parts broken within warranty?

A: We would express the free replacement parts during the warranty date.

Q: How many worker do we need running those machines?

A: For flexo printing, slitting, die-cutting machine, only need one person for each.

Q: What should we charge for your engineer?

A: You should charge for the cost of our engineer's visa , air tickets, hotel, food ,and also their salary 100USD one day per

person.

Hot Searches