- Product Details

- {{item.text}}

Quick Details

-

Shelf Life:

-

12 months

-

Apperance:

-

liquid

-

viscosity:

-

adjustable

-

hardness:

-

5-40 shore A

-

mix ratio:

-

1:1 or 10:1

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Inibaba

-

Color:

-

white, translucent,red,

-

Shelf Life:

-

12 months

-

Apperance:

-

liquid

-

viscosity:

-

adjustable

-

hardness:

-

5-40 shore A

-

mix ratio:

-

1:1 or 10:1

Products Description

Description

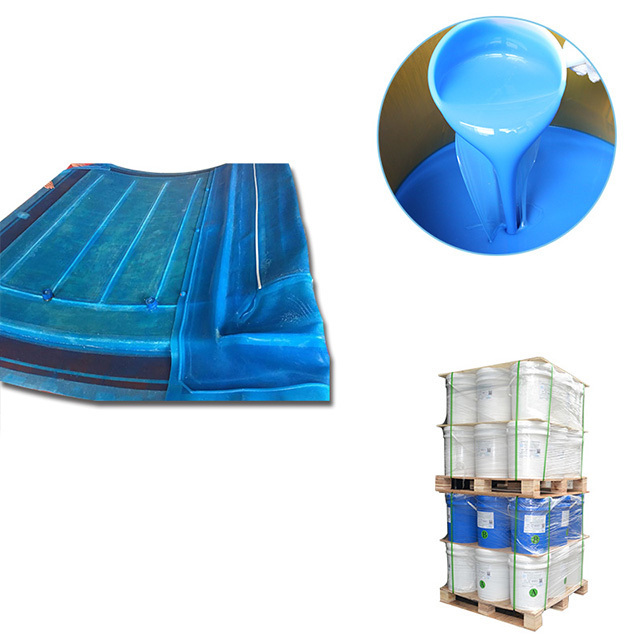

fluid liquid silicone rubber silicone compound platinum based to work in a vacuum chamber

Mold making silicone rubber provided by Inibaba is two components silicone, also called rtv2 silicone, which will be vulcanized in room temperature when mix part A and part B evenly. platinum cure silicone and addition cure silicone, the general mix ratio of A and B is 1:1 or 10:1.

Mold making silicone rubber provided by Inibaba is two components silicone, also called rtv2 silicone, which will be vulcanized in room temperature when mix part A and part B evenly. platinum cure silicone and addition cure silicone, the general mix ratio of A and B is 1:1 or 10:1.

Application and Advantages

Mold making silicone rubber for reproducing and replicating art crafts, furniture, prototyping, architectural elements, garden ornaments, shoe, tire, soap, candle, jewelry, vacuum bag and so on, since molding silicone is suitable for casting resin, PU, PVC, polyester, gypsum, plaster, concrete, cement, stone, GRC, wax, jewelry and so on.

Advantages:

Good flow performance

Easy to operate

Low viscosity

Easy demold

Low shrinkage(<0.1%)

No deformation

No whitening

High temperature resistant(-65C-350C)

Flexible and low viscosity which will copy finest details and patterns from exquisite products.

Aging resistance, acid and alkali resistance nontoxic, odorless

Mold making silicone rubber for reproducing and replicating art crafts, furniture, prototyping, architectural elements, garden ornaments, shoe, tire, soap, candle, jewelry, vacuum bag and so on, since molding silicone is suitable for casting resin, PU, PVC, polyester, gypsum, plaster, concrete, cement, stone, GRC, wax, jewelry and so on.

Advantages:

Good flow performance

Easy to operate

Low viscosity

Easy demold

Low shrinkage(<0.1%)

No deformation

No whitening

High temperature resistant(-65C-350C)

Flexible and low viscosity which will copy finest details and patterns from exquisite products.

Aging resistance, acid and alkali resistance nontoxic, odorless

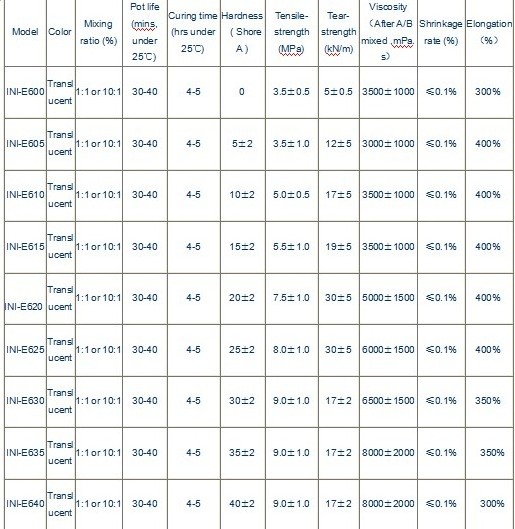

Parameter

Free Sample for your test.

Free Sample for your test.

Operation

Pour and Brush

Pour and Brush

Operation Instruction

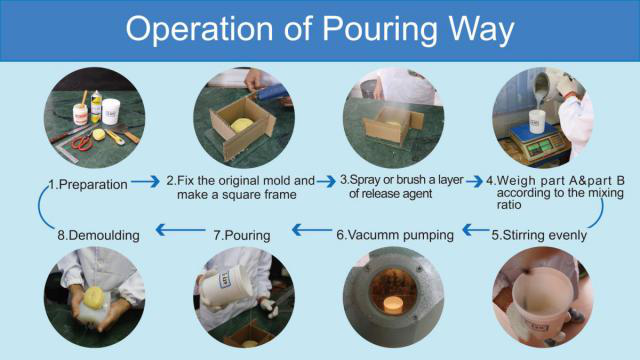

Step 1: prepare the original molds

Make sure your original molds perfect. fix it on a board. And fix the original mold on a board , then used four piece of board to enclose the original molds .

Step 2: Take 100 G parts A and add 3G parts B and mix them evenly.

*Notes: Mold making silicon rubber is a kind of flowing liquid ,it contains two parts. Part A is a kind of flowing white liquid and part B is the curing agent or catalyst .Pls follow the step strictly:

1.Weigh the two part exactly by electronic weight..

If not , for example add two much catalyst , the operation time will be too fast to operate ,which will cause inconvinience to operate .

2.Mix part A and part B evenly.

Otherwise the silicon rubber will be partly solidified and this will give birth to difficulties in your final operation. What’s

more, the finished molds will meet a short life. All of these will cause a waste of silicon rubber.

Step 3: Vacuum pumping

Without exception, this step takes less than 10 minutes. Otherwise, it will cause cross linking reaction, and no more further

steps will be available.

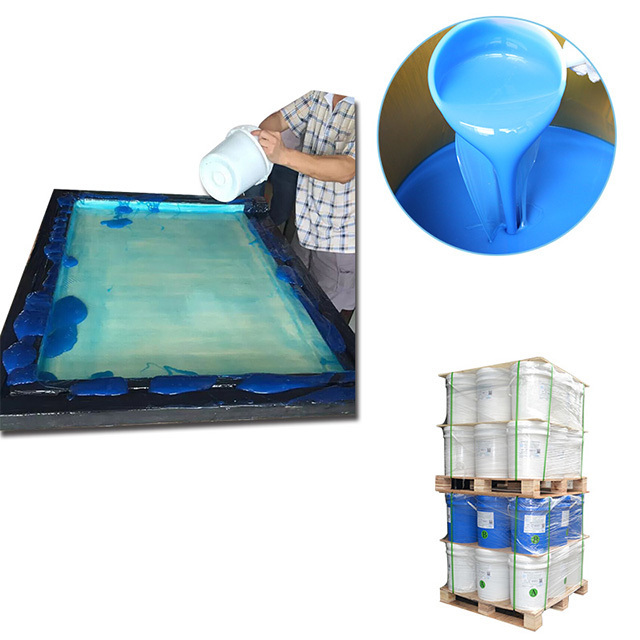

Step 4: Pouring casting or Brush operation

*Notes:1. For simple pattern products we suggest use pouring operation way , which will be very easy to operate and demould. Pourable silicone require light viscosity which will be easy to flow smoothly and easy to de-air .

2.For delicate pattern products we suggest use brushing operation way , which can copy the pattern exactly . Brushable silicone require high viscosity which won’t be easy to flow away and easy to brush .

3. We suggest to set the silicone mold for another 12 hours after demould before put into large production .

Warm tips :

1. As addition cure silicone is a kind of platinum cure system ,which will be easy to cause uncure problem ,so Kindly follow the tips below :

*Do not mix with liquid condensation silicone rubber or even the tool which used for condensation silicone

*Do not mix with organic matter which contains N, S, P organics and ionic compound like Sn, As,Hg, Ph,

*Do not add any pigment or powder into the addition cure silicone rubber without any testing to prevent uncure problem

Make sure your original molds perfect. fix it on a board. And fix the original mold on a board , then used four piece of board to enclose the original molds .

Step 2: Take 100 G parts A and add 3G parts B and mix them evenly.

*Notes: Mold making silicon rubber is a kind of flowing liquid ,it contains two parts. Part A is a kind of flowing white liquid and part B is the curing agent or catalyst .Pls follow the step strictly:

1.Weigh the two part exactly by electronic weight..

If not , for example add two much catalyst , the operation time will be too fast to operate ,which will cause inconvinience to operate .

2.Mix part A and part B evenly.

Otherwise the silicon rubber will be partly solidified and this will give birth to difficulties in your final operation. What’s

more, the finished molds will meet a short life. All of these will cause a waste of silicon rubber.

Step 3: Vacuum pumping

Without exception, this step takes less than 10 minutes. Otherwise, it will cause cross linking reaction, and no more further

steps will be available.

Step 4: Pouring casting or Brush operation

*Notes:1. For simple pattern products we suggest use pouring operation way , which will be very easy to operate and demould. Pourable silicone require light viscosity which will be easy to flow smoothly and easy to de-air .

2.For delicate pattern products we suggest use brushing operation way , which can copy the pattern exactly . Brushable silicone require high viscosity which won’t be easy to flow away and easy to brush .

3. We suggest to set the silicone mold for another 12 hours after demould before put into large production .

Warm tips :

1. As addition cure silicone is a kind of platinum cure system ,which will be easy to cause uncure problem ,so Kindly follow the tips below :

*Do not mix with liquid condensation silicone rubber or even the tool which used for condensation silicone

*Do not mix with organic matter which contains N, S, P organics and ionic compound like Sn, As,Hg, Ph,

*Do not add any pigment or powder into the addition cure silicone rubber without any testing to prevent uncure problem

Why Choose us

1. Powerful factory with a production capacity of 9000 per day

2. High-end research and development (free sample)

Being a leading liquid silicone manufacturer in China, we have a professional R&D team and QC team(12 experts ) and our product is RoHS, MSDS, ISO, REACH, UL approved, so there is no need to worry about the quality.

Being a leading liquid silicone manufacturer in China, we have a professional R&D team and QC team(12 experts ) and our product is RoHS, MSDS, ISO, REACH, UL approved, so there is no need to worry about the quality.

3,Efficient service

We can provide free training of silicone technique and free silicone samples. we have a professional sales team who will solve your problems patiently. Besides, with efficient logistics distribution system, you could get you goods earlier. Last, good after-sales service,we build long term cooperation relationship, once there is quality problem, we could solve right away. More importantly, return and exchange are accepted while quality problems occurred

We can provide free training of silicone technique and free silicone samples. we have a professional sales team who will solve your problems patiently. Besides, with efficient logistics distribution system, you could get you goods earlier. Last, good after-sales service,we build long term cooperation relationship, once there is quality problem, we could solve right away. More importantly, return and exchange are accepted while quality problems occurred

Certifications

Package

1kg/drum,5kg/drum, 20kg/drum,25kg/drum, 200kg/drum.

SHELF LIFE

Twelve (12) months from date of shipment when stored at 25°C in original unopened packages

1kg/drum,5kg/drum, 20kg/drum,25kg/drum, 200kg/drum.

SHELF LIFE

Twelve (12) months from date of shipment when stored at 25°C in original unopened packages

We can provide the free sample, more details about silicone rubber, pls contact Ms Lisa at:

Mobile/ Whatsapp/: +86 188 1670 2967

Wechat: + 86 188 1670 2967 or A108059

E-mail: lisasilicone(at)inibaba(dot)com

Twitter/Facebook:lisasilicone

Mobile/ Whatsapp/: +86 188 1670 2967

Wechat: + 86 188 1670 2967 or A108059

E-mail: lisasilicone(at)inibaba(dot)com

Twitter/Facebook:lisasilicone

Hot Searches