- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Ultrasonic Food Cutting Blade

-

Ultrasonic Frequency:

-

20KHz

-

Voltage:

-

AC 110V/220V-50/60HZ

-

Power:

-

800W

-

Knife Width:

-

100~350mm Customizable

-

Knife Material:

-

Ti Alloy

-

Ultrasonic Knife Height:

-

60mm Customizable

-

Cutting Accuracy:

-

±0.2mm

-

After Warranty Service:

-

Video technical support

Quick Details

-

Weight (KG):

-

40

-

Place of Origin:

-

GuangDong

-

Brand Name:

-

XWELL

-

Product name:

-

Ultrasonic Food Cutting Blade

-

Ultrasonic Frequency:

-

20KHz

-

Voltage:

-

AC 110V/220V-50/60HZ

-

Power:

-

800W

-

Knife Width:

-

100~350mm Customizable

-

Knife Material:

-

Ti Alloy

-

Ultrasonic Knife Height:

-

60mm Customizable

-

Cutting Accuracy:

-

±0.2mm

-

After Warranty Service:

-

Video technical support

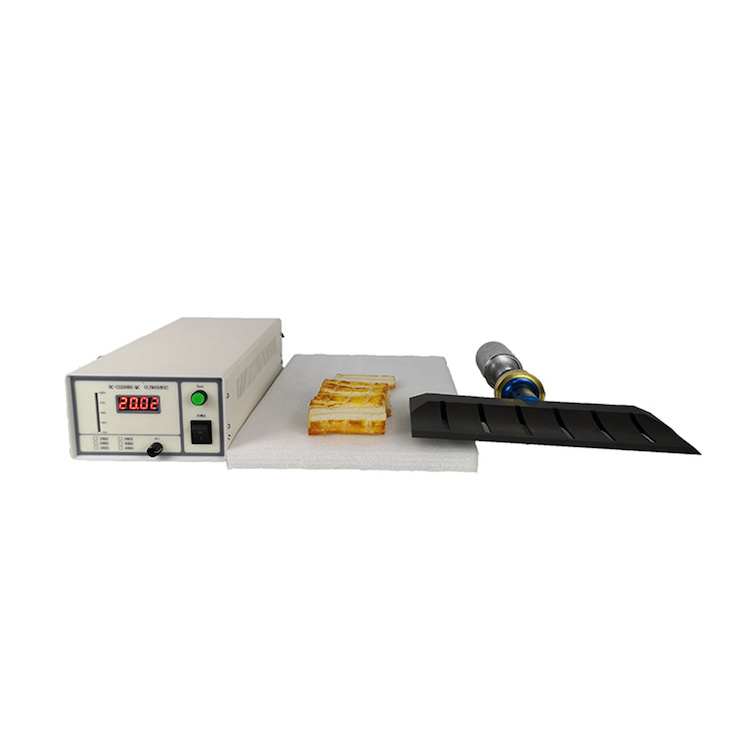

Product Overview

Ultrasonic food cutting machine

Uses high frequency wave vibration to quickly process food, eliminating the traditional cutting blade continuous cleaning caused by downtime.

Ultrasonic food cutting machine provide a new approach to cutting, slicing, and automatically turning to handle a variety of foods, making the production process, waste minimization and maintenance costs the lowest.

Ultrasonic food cutting equipment is the use of ultrasonic energy generated 20,000 times per second high-frequency vibration between the blade and food to establish a surface almost no friction, so eliminate sticky knives and squeezing and other issues.

Features

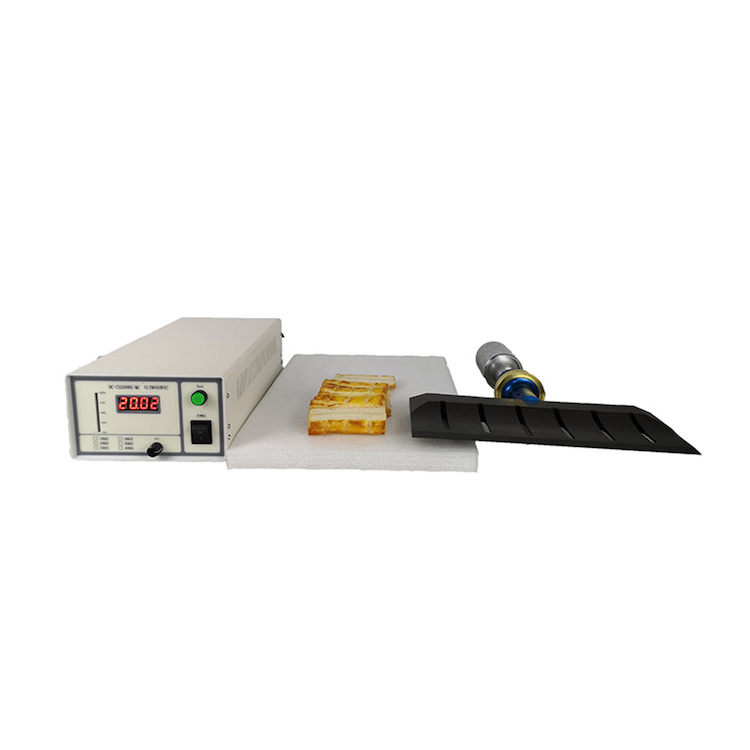

*1.The use of ultrasonic energy cutting to reduce friction, long service life

*2.Significantly increased processing speed without the need for cleaning

*3.Viscous materials such as butter do not stick knife, cut surface smooth and beautiful

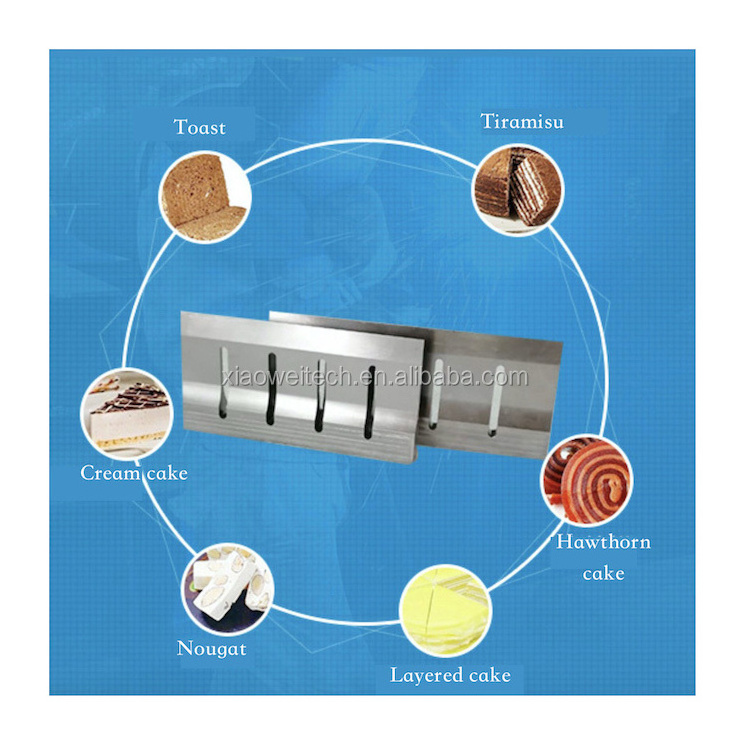

*4.Wide range of food cutting objects, candy and cake categories are applicable

*5.Cutting constant temperature, high temperature and low temperature environment can work

*2.Significantly increased processing speed without the need for cleaning

*3.Viscous materials such as butter do not stick knife, cut surface smooth and beautiful

*4.Wide range of food cutting objects, candy and cake categories are applicable

*5.Cutting constant temperature, high temperature and low temperature environment can work

Cabinet type u

ltrasonic food cutting machine

Totally enclosed

Manual machine

Multiple options

Specifications

|

No

|

Item

|

Parameter

|

|

1

|

Brand Name

|

XWELL

|

|

2

|

Machinery Function

|

Ultrasonic Food Cut

|

|

3

|

Ultrasonic Knife Height

|

60mm Customizable

|

|

4

|

Knife Width

|

100-350mm

|

|

5

|

Knife Material

|

Ti Alloy

|

|

6

|

Cutting Accuracy

|

±0.2mm

|

|

7

|

Power supply

|

Single phase 220V/Three phase 380V

|

|

8

|

Power

|

800 W

|

|

9

|

Size

|

480*320*285(mm)

|

|

10

|

Weight

|

40kg

|

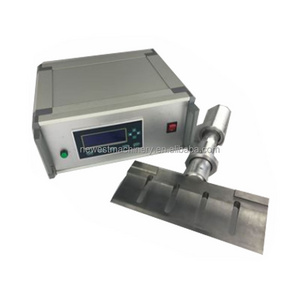

Details Images

Ultrasonic food cutting machine

Our ultrasonic food cutting machines are fully automatic and manual, as well as desktop and closed cabinet machines

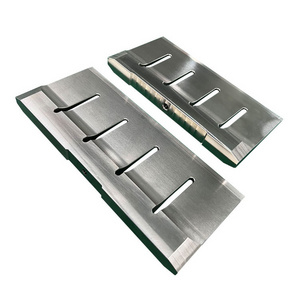

Custom accessories

High quality blades of various sizes and various types of ultrasonic generators can be customized

Samples

Ultrasonic cutting

samples

*1.The use of ultrasonic energy cutting to reduce friction, long service life

*2.Significantly increased processing speed without the need for cleaning

*3.Viscous materials such as butter do not stick knife, cut surface smooth and beautiful

*4.Wide range of food cutting objects, candy and cake categories are applicable

*5.Cutting constant temperature, high temperature and low temperature environment can work

*2.Significantly increased processing speed without the need for cleaning

*3.Viscous materials such as butter do not stick knife, cut surface smooth and beautiful

*4.Wide range of food cutting objects, candy and cake categories are applicable

*5.Cutting constant temperature, high temperature and low temperature environment can work

Projects

India project

This project is localed in Inda,

Gurgaon. The client was founded in 1994, have more than 400 staffs and 10000+ square factory.

They bought 2 full of battery pack assembly line from us, includes sorting machine, welding machine, sticking machine, charge and discharge machine...

We have sent 3 engineers to client site for machine installation and training in year of 2019. The training taked about one week. After the training, the client engineers are learned how to operation the machines in a smooth and

high efficiency

way.

They made high-quality products by our machines.

We had a nice

journey in India.

Hot Searches