- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

1500 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

2.5KW

-

Product name:

-

Canned Tomato Production Line

-

Application:

-

Food Processing Machine

-

Final product:

-

Canned Food

-

Material:

-

Food Grade Stainless Steel

-

Advantage:

-

Easy Operation High Efficiency

-

Type:

-

Fully Automatic

-

Function:

-

Multifunctional

-

Feature:

-

Automatic Production

-

Usage:

-

Vegetable Processing Inductries

Quick Details

-

Machinery Capacity:

-

OEM

-

Brand Name:

-

LWT

-

Year:

-

OEM

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

1500 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

2.5KW

-

Product name:

-

Canned Tomato Production Line

-

Application:

-

Food Processing Machine

-

Final product:

-

Canned Food

-

Material:

-

Food Grade Stainless Steel

-

Advantage:

-

Easy Operation High Efficiency

-

Type:

-

Fully Automatic

-

Function:

-

Multifunctional

-

Feature:

-

Automatic Production

-

Usage:

-

Vegetable Processing Inductries

Product Description

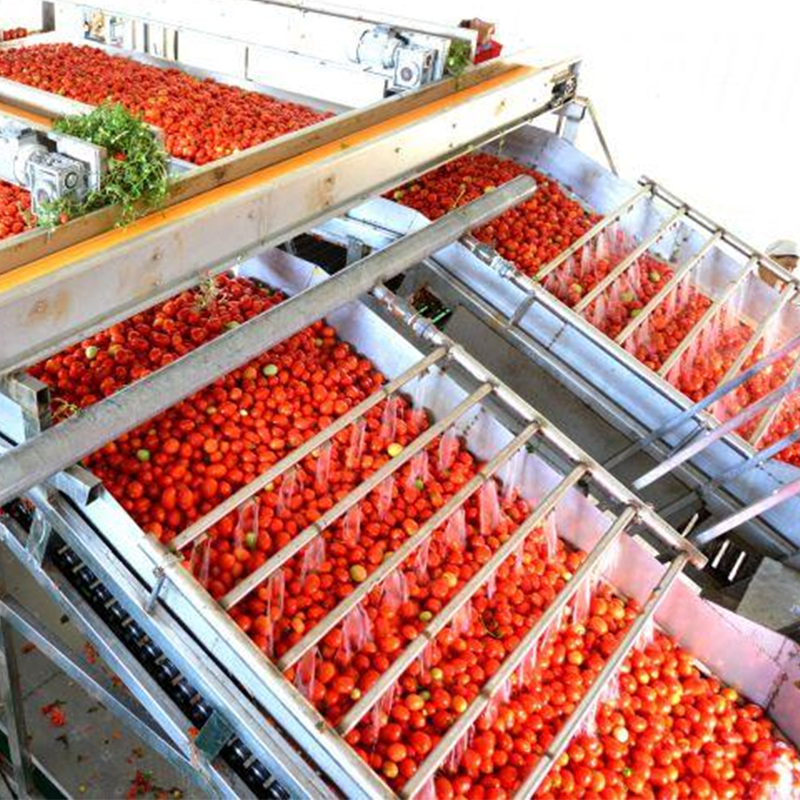

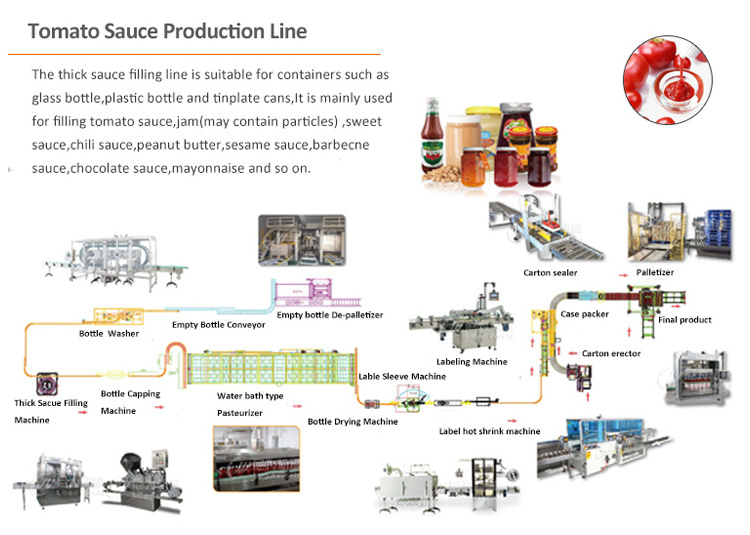

Tomato Paste Filling Production Line

1.tomato (fruit or vegetable) → 2.Digging nuclear →3.Turnover→4.Soda water spraying→5.Peeler and cleaner → 6.pre-cooked →7.cooling → 8.pick → 9.go hair→10.Slicer →11.Filling(←Botte washing←Depalletizer)→12.Pouring juice→13.Exhauster→14.Sealing→15.Canned tomato→16.Sterilization→17.Dryer→18.Cans Palletizer→19.Warehousing→20.Labeler→21.Finished

product→22.Case packer→23.Case Palletizer→24.Shipments

1.tomato (fruit or vegetable) → 2.Digging nuclear →3.Turnover→4.Soda water spraying→5.Peeler and cleaner → 6.pre-cooked →7.cooling → 8.pick → 9.go hair→10.Slicer →11.Filling(←Botte washing←Depalletizer)→12.Pouring juice→13.Exhauster→14.Sealing→15.Canned tomato→16.Sterilization→17.Dryer→18.Cans Palletizer→19.Warehousing→20.Labeler→21.Finished

product→22.Case packer→23.Case Palletizer→24.Shipments

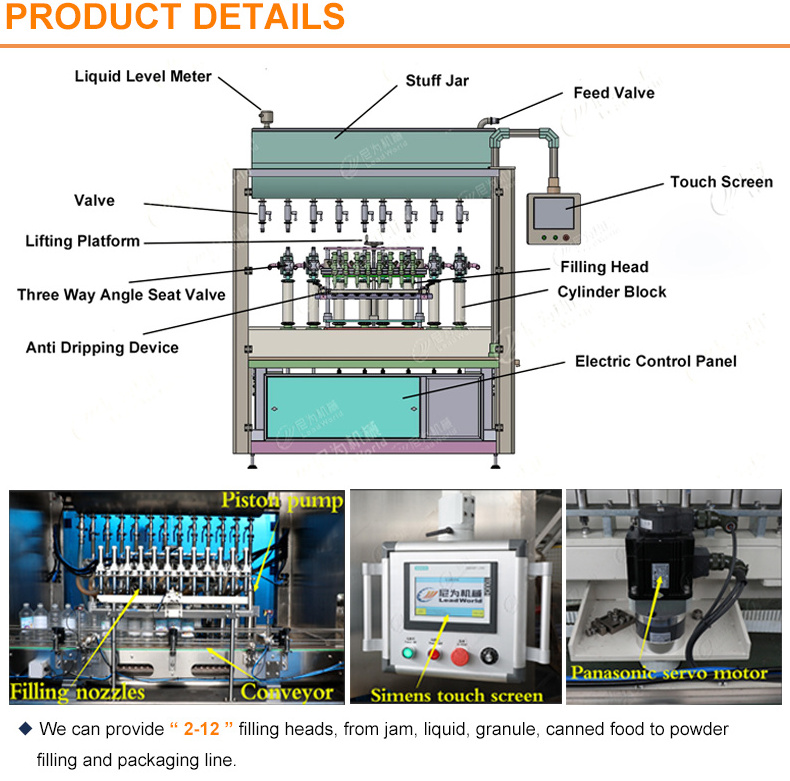

Features:

1. Vacuum Preventing Leaking System

2. No Bottle or Lack of Bottle, No Filling System

3. Photoelectric Sensor, Mechatronics Filling Adjustment System

4. Photoelectric Sensor, Material Level Control Feeding System

5. Stainless Steel Frame,Plexiglass as Security Cover

6. Control System: PLC/Electronic-Pneumatic Controlled

7. Operation Panel: "Intelligent" Colorful Touch Screen

8. Filling Accuracy:+-5%

9. Capacity Adjustment:All cylinders adjusted automatically combine single cylinder adjusted individually.

10.Container transport:Stainless steel frame and engineering plastic plate chain variable speed conveyor, with photoelectric

sensor

1. Vacuum Preventing Leaking System

2. No Bottle or Lack of Bottle, No Filling System

3. Photoelectric Sensor, Mechatronics Filling Adjustment System

4. Photoelectric Sensor, Material Level Control Feeding System

5. Stainless Steel Frame,Plexiglass as Security Cover

6. Control System: PLC/Electronic-Pneumatic Controlled

7. Operation Panel: "Intelligent" Colorful Touch Screen

8. Filling Accuracy:+-5%

9. Capacity Adjustment:All cylinders adjusted automatically combine single cylinder adjusted individually.

10.Container transport:Stainless steel frame and engineering plastic plate chain variable speed conveyor, with photoelectric

sensor

Other products

1.Empty Cans/jars De-palletizer

Descriptions

:

Empty cans de-palletizer is mainly composed of lifting mechanism, moving mechanism, magnetic suction mechanism, conveyor and electrical controlling system. The working way adopts magnetic suction and moving type. It can match with magnetic lifting conveying system, can transport product in the air and can transport product among different height of floor.

2.Empty jar washing machine

Descriptions:

The machine is used for glass jar continued cleaning,adopt steam heating way,temperature is adjustable,it adopt high pressure standard nozzle. It has good cleaning efficiency,reasonable structure,stable work performance,high efficiency,it is ideal equipment of canned food beverage production line.

3.Liquid Filling Machine

liquid filling machine widely used in :sauce,oil,juice drink,water,wine,dairy products

|

Moldel

|

Capacity

|

Filling volume

|

|

LW-FPP-4A

|

480bph-720bph

|

10-60g

30-100g 50-250g 100-500g 200-1000g 500-2500g 1000-5000g |

|

LW-FPP-6A

|

960bph-1920bph

|

|

|

LW-FPP-8A

|

1440bph-2880bph

|

|

|

LW-FPP-10A

|

1920bph-3840bph

|

|

|

LW-FPP-12A

|

2400bph-4800bph

|

|

4.Sterilization Machine

It is mainly applied to all kinds of cans of drinks, tin cans of drink, canned meat, canned vegetables and secondary sterilization plastic bottle beverage etc process loading automatically before sterilization,unloading after sterilization,replace the artificial working,save manpower, greatly improve production efficiency.The machine adopts magnetic suction to prevent the chafing and squeezing of the cans.

5.Filled Cans Washing and Drying Machine

It is applied to clean and dry outside surface of all kinds of canned fruit,canned meat,bottled sauce and all kinds of drinks.(specializedin washing and drying the adhensive sugar water and otheradhenionoutside of the sealed canned products or beverage),applying for tin cans,glass bottles and plastic bottles.

6.Labeling Machine

It Adopts enclosed transmission box,full mechanical

transmission,

adhesive attached to various round bottle labels,stable and reliable.suitable for round pot labeling.

7.Cans Palletizer/De-palletizer

Filled Cans Palletizer is suitable for palletizer and depalletizer of the filled glass bottles,filled tin cans,empty tin cans,it is main composed of conveying system and palletizing system.Working way uses magnetic grabmovement.

9. Case Packer

Carton packing machine has the characteristics of simple structure, easy to maintain.Use Siemens PLC, Danfoss transducer,Schneider low-voltage electrical appliances and the SEW motor,the machine performance is stable and reliable .

Hot Searches