- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

50

-

Weight (KG):

-

8500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model:

-

DH-1200

-

Pressure of hydraulic system:

-

1200kn

-

Chamber size:

-

1200*700*600mm

-

Finished block size:

-

(250-450)*250*250

-

Mass density:

-

more than 2000kg/m3

-

Capacity:

-

1500-2000kg/h

-

Single cycle time:

-

110s

-

Motor Powder:

-

18.5kw

-

Control system:

-

PLC, Semi or full automatic

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dihai

-

Marketing Type:

-

Hot Product 2022

-

Power (kW):

-

50

-

Weight (KG):

-

8500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model:

-

DH-1200

-

Pressure of hydraulic system:

-

1200kn

-

Chamber size:

-

1200*700*600mm

-

Finished block size:

-

(250-450)*250*250

-

Mass density:

-

more than 2000kg/m3

-

Capacity:

-

1500-2000kg/h

-

Single cycle time:

-

110s

-

Motor Powder:

-

18.5kw

-

Control system:

-

PLC, Semi or full automatic

Products Description

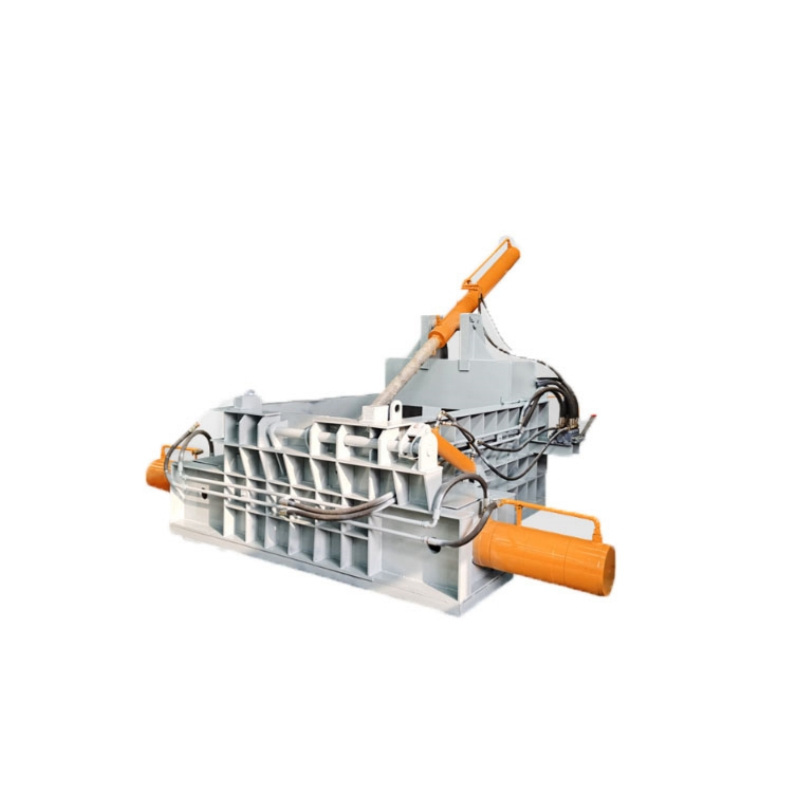

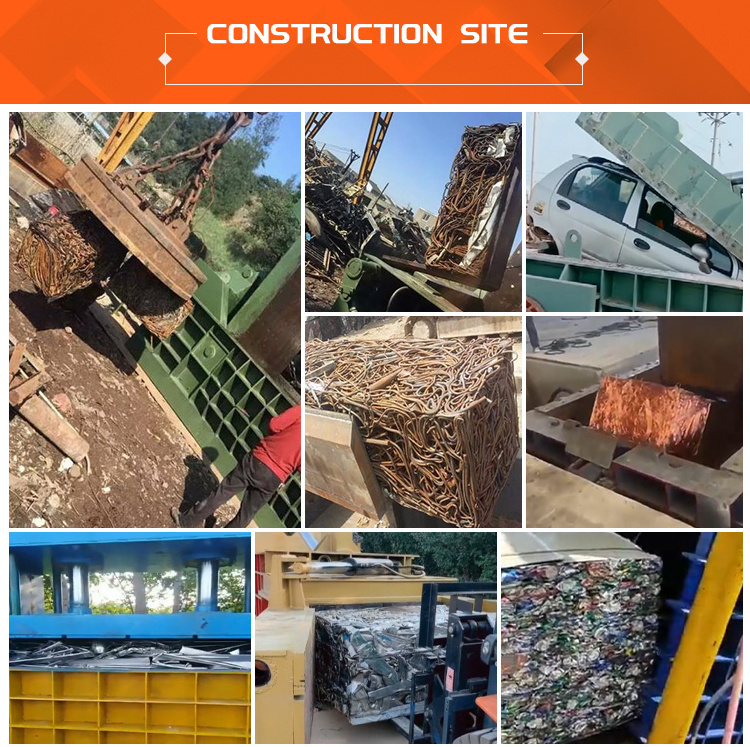

Our compactor, also known as briquetting machine , has a wide range of styles and powerful functions.

For the recycling of waste metals, the following models are mainly introduced here.

The hydraulic cylinders on the machine provide pressure in the vertical direction, horizontal direction, and three lateral directions respectively.

If you want to choose a metal briquetting machine with low cost, small footprint and easy operation. It is recommended that you use the vertical model.

If there is a large amount of scrap metal, you want to feed it automatically, and you want to get large bales, a horizontal baler is an economical and practical choice. Equipped with an automatic plate chain conveyor, it is even more powerful.

Our star model, muti-cylinder metal baler, multiple hydraulic cylinders work together to provide strong pressure. As materials enter and exit, the most troublesome scrap steel bars can be pressed into a square shape.

Product Parameters

|

No.

|

Main Cylinder Pressure

|

Chamber size/mm

|

Bale size/mm

|

Bale weight about

|

Motor power

|

|

1

|

125 tons

|

1400*800*600

|

300*300*(300-600)

|

50 kgs

|

18.5kw

|

|

2

|

160 tons

|

1600*1200*700

|

400*400*(600-900)

|

100 kgs

|

22kw*2

|

|

3

|

200 tons

|

1800*1500*800

|

500*500*(700-1200)

|

250 kgs

|

22kw*2

|

|

4

|

250 tons

|

2000*1750*1000

|

500*500*(800-1200)

|

400 kgs

|

30kw*2

|

|

5

|

315 tons

|

2500*2000*1000

|

500*500*(800-1500)

|

1000 kgs

|

30kw*2

|

|

6

|

400 tons

|

3000*2500*1200

|

600*600*(900-1500)

|

1200 kgs

|

37kw*2

|

|

7

|

630 tons(for pressing car)

|

3500*3000*1300

|

700*700*(900-1500)

|

1500 kgs

|

37kw*3

|

The metal briquetting machine contributes to the recycling industry with its wear-resistant and strong and stable characteristics. Whether it is scrap cars, colored steel tiles, construction steel bars, bicycles, cans, aluminum and iron scraps, etc., as long as it needs to be recycled, there is always a briquetting machine that is suitable for you.

Your needs are the direction of our efforts:

It is precisely because of our full cooperation with our customers that we have completed each perfect work.

1. Hydraulic cylinder: adopts solid piston rod with strong pushing force;

2. Install a cutter: easily cut various metal scraps;

3. Operation method: Whether it is an independent operating lever, remote control, or PLC button control, it is simple and safe;

4. Bin: additional wear-resistant plate, durable for a long time;

5. Cooling method: water cooling, air cooling or air conditioning, you can choose according to the environment.

Hot Searches