- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1200 KG

-

Applicable Industries:

-

Other

-

Product name:

-

Compressed Wood Pallet Block Leg Pier Making Machine

-

Application:

-

wood pallet blocks making

-

Raw material:

-

Sawdust, wood shaving within 5mm

-

Type:

-

wooden pallet leg Hot Pressing

-

Color:

-

Customers' Demand

-

Block density:

-

550-600kg/m3

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Capacity:

-

4-6 m3/24hrs

-

Block type:

-

solid or hollow block

-

Wooden block standard:

-

can do north american or euro standard block

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gashili

-

Machine Type:

-

wood pallet block press

-

Weight (KG):

-

1200 KG

-

Applicable Industries:

-

Other

-

Product name:

-

Compressed Wood Pallet Block Leg Pier Making Machine

-

Application:

-

wood pallet blocks making

-

Raw material:

-

Sawdust, wood shaving within 5mm

-

Type:

-

wooden pallet leg Hot Pressing

-

Color:

-

Customers' Demand

-

Block density:

-

550-600kg/m3

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Capacity:

-

4-6 m3/24hrs

-

Block type:

-

solid or hollow block

-

Wooden block standard:

-

can do north american or euro standard block

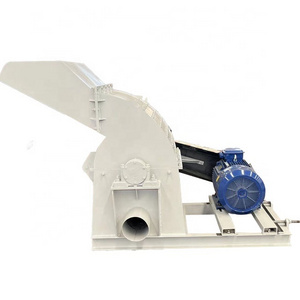

High quality Compressed Wood Pallet Block Leg Pier Making Machine

Product Description

|

Name

|

Four-head pallet blocks making machine

(Can do block size: 75-145mm) Solid or Hollow blocks? need to confirm before production. |

|

Motor

|

12-16kw

|

|

Capacity

|

4-6 m3/24h (different for different materials)

|

|

Density

|

550-600kg/m3

|

|

Material consumption

|

550-600kg/m3(wood shavings,saw dust)

|

|

Glue consumption

|

80-100kg/m3

|

|

Temperature control

|

PID

|

|

Dimension

|

4800*760*1300mm

|

|

Weight

|

1200 Kg

|

Four-heads wood pallet block machine

Introduce:

1. Mainly uses wood sawdust, shaving, chips or other scrap woods and others agricultural waste like cotton seeds, shell husks as raw materials, mixing with glue in an certain ratio, extruding wood pallet block by hot press heating pressure.

2. Is one of the key parts of the pallet block production line, including wood crusher, wood drying machine, gluing machine, conveyor, manual or automatic cutting machine or saw.

3. The final wood pallet block can be used as pallet foot replaced log, also can be used in export package.

Advantages for

Wood pallet block machine

:

1. Simple machine, and easy operation. One person could handle 3 or 4 machines.

2. High efficiency. Output is 4-6 m3/24h.

3. Cross-section is completely vertical, reducing the previous cutting loss.

4. Setting the cutting length by entering the value, fully automatic, and suitable for the specifications of pallet block.

5. Saving the production cost and enhancing the process of automation.

6. Pallet block machine could recycle the wood waste efficiently.

7. Free fumigation. Because the pallet block is made by hot pressing, it is free fumigation.

Specification

Two-head pallet blocks making machine (can do block size: 75-145mm)

Capacity: 2-3 m3/24h

Capacity: 2-3 m3/24h

Six-head pallet blocks making machine (can do block size: 75-100mm)

Capacity: 6-8 m3/24h

Raw materials:

1. Wood shavings, chips, sawdust and other wood waste materials (the moisture content is around 10%-12%).

2. Urea formaldehyde glue.(Suggest buy it locally)

1. Block sizes are optional

2. Meeting the E1 grade.

3. Insect prevention, protection against termites and do not easy to burn.

4. Free fumigation and free quarantine.

Packing & Delivery

Plastic film+plywood case

FAQ

Before quotation, we need confirm ,

1, your block size?

2, hollow or solid block?

3, only wood pallet block making machine needed or one complete wood pallet block production line needed?

4, if complete line, what will be the raw material and what is the moisture of the raw material?

5, our motor is 380-415V, 50HZ, 3-phase. If different, what is yours?

6, if need CFR or CIF price, which will be the destination port?

Hot Searches