- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

HICHWAN

-

Model Number:

-

QW, QW

-

Place of Origin:

-

Shandong, China

-

Horsepower:

-

To be selected

-

Outlet Size:

-

50mm-600mm

-

Power:

-

1.5KW-315 KW

-

motor:

-

100% Copper Wire

-

Submersible slurry pump:

-

Submersible Sewage Pump

-

submersed sand mud pump:

-

electric water pump

-

Pump Type:

-

Vertical or Horizontal Pump

-

Material:

-

Ss or Cast Iron

-

Color:

-

The choice is yours

-

Standard or Nonstandard:

-

Standard

-

Coupling Installation:

-

Support

-

Head:

-

To be negotiated

Quick Details

-

Application:

-

Commercial Buildings, Developing World Water Solutions, Family Homes, Industrial Utilities, Machining, Metal and Equipment Manufacturers, Mining industry, Pharmaceutical industry, Washing and Cleaning, Wastewater Transport and Flood Control, wastewater treatment, Water Treatment Solutions, chemical plant, cement plant, steel works, coal processing, paper industry

-

Pressure:

-

High Pressure

-

Voltage:

-

380V/660V/1140V

-

Warranty:

-

1 year

-

Brand Name:

-

HICHWAN

-

Model Number:

-

QW, QW

-

Place of Origin:

-

Shandong, China

-

Horsepower:

-

To be selected

-

Outlet Size:

-

50mm-600mm

-

Power:

-

1.5KW-315 KW

-

motor:

-

100% Copper Wire

-

Submersible slurry pump:

-

Submersible Sewage Pump

-

submersed sand mud pump:

-

electric water pump

-

Pump Type:

-

Vertical or Horizontal Pump

-

Material:

-

Ss or Cast Iron

-

Color:

-

The choice is yours

-

Standard or Nonstandard:

-

Standard

-

Coupling Installation:

-

Support

-

Head:

-

To be negotiated

Product Description

CONDITIONS OF USE

1. Motor rated voltage 380V(660V),

frequency 50Hz three-phase AC power supply.

2. Conveying medium temperature does not exceed 40P.

3. Conveying liquid medium PH value is 4~10.

4. The volume ratio of solids in the conveying medium is below 2%.

5. Conveying medium density is less than 1.2x103kg/m3.

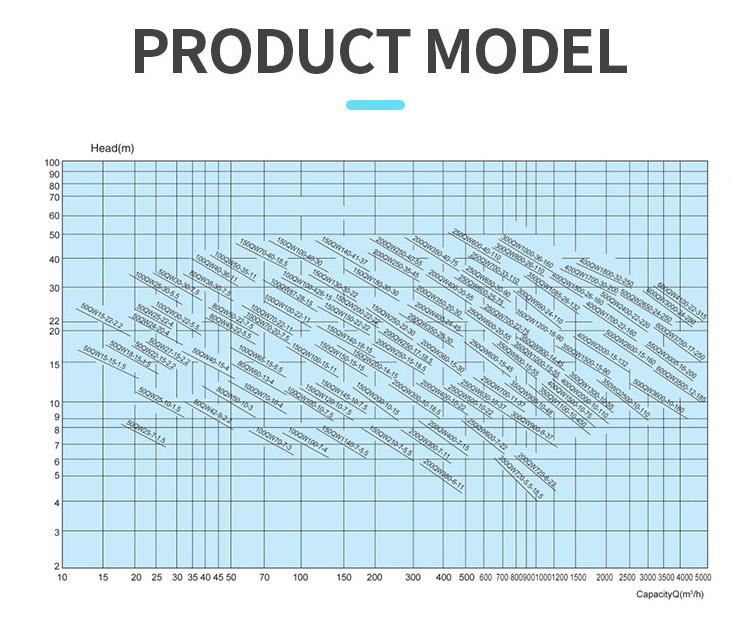

Product Paramenters

Only some models are shown,please contact us for more parameters.

|

Model number

|

Discharge caliber

|

flow rate

|

head

|

Motor power

|

rotate speed

|

|

|

(mm)

|

(m3/h)

|

(m)

|

|

(r/min)

|

|

|

|

|

|

(kw)

|

|

|

50QW15-15-1.5

|

50

|

15

|

15

|

1.5

|

2860

|

|

50QW18-15-1.5

|

50

|

18

|

15

|

|

|

|

50QW25-7-1.5

|

50

|

25

|

7

|

|

|

|

50QW25-10-1.5

|

50

|

25

|

10

|

|

|

|

50QW15-22-2.2

|

50

|

15

|

22

|

2.2

|

2860

|

|

50QW22-15-2.2

|

50

|

22

|

15

|

|

|

|

50QW27-15-2.2

|

50

|

27

|

15

|

|

|

|

50QW42-9-2.2

|

50

|

42

|

9

|

|

|

|

80QW50-10-3

|

80

|

50

|

10

|

3

|

2860

|

|

100QW70-7-3

|

100

|

70

|

7

|

|

|

|

50QW24-20-4

|

50

|

24

|

20

|

4

|

2860

|

|

50QW25-22-4

|

50

|

25

|

22

|

|

|

|

50QW40-15-4

|

50

|

40

|

15

|

|

|

|

80QW60-13-4

|

80

|

60

|

13

|

|

|

|

100QW70-10-4

|

100

|

70

|

10

|

|

|

|

100QW100-7-4

|

100

|

100

|

7

|

|

|

|

100QW25-30-5.5

|

100

|

25

|

30

|

5.5

|

2860

|

|

80QW45-22-5.5

|

80

|

45

|

22

|

|

|

|

100QW30-22-5.5

|

100

|

30

|

22

|

|

|

|

100QW65-15-5.5

|

100

|

65

|

15

|

|

|

|

150QW120-10-5.5

|

150

|

120

|

10

|

|

|

|

150QW140-7-5.5

|

150

|

140

|

7

|

|

|

|

50QW30-30-7.5

|

50

|

30

|

30

|

7.5

|

1450

|

|

80QW38-30-7.5

|

80

|

38

|

30

|

|

|

|

80QW50-22-7.5

|

80

|

50

|

22

|

|

|

|

100QW70-20-7.5

|

100

|

70

|

20

|

|

|

|

150QW145-10-7.5

|

150

|

145

|

10

|

|

|

|

150QW210-7-7.5

|

150

|

210

|

7

|

|

|

|

100QW50-35-11

|

100

|

50

|

35

|

11

|

1450

|

|

100QW40-36-11

|

100

|

40

|

36

|

|

|

|

100QW100-22-11

|

100

|

100

|

22

|

|

|

|

100QW70-22-11

|

100

|

70

|

22

|

|

|

|

150QW100-15-11

|

150

|

100

|

15

|

|

|

|

200QW300-7-11

|

200

|

300

|

7

|

|

|

|

200QW360-6-11

|

200

|

360

|

6

|

|

|

|

100QW87-28-15

|

100

|

87

|

28

|

15

|

|

|

100QW100-28-15

|

100

|

100

|

28

|

|

|

|

100QW140-18-15

|

100

|

140

|

18

|

|

|

|

150QW150-15-15

|

150

|

150

|

15

|

|

|

|

150QW200-10-15

|

150

|

200

|

10

|

|

|

|

150QW200-14-15

|

150

|

200

|

14

|

|

|

|

200QW400-7-15

|

200

|

400

|

7

|

|

|

|

150QW70-40-18.5

|

150

|

70

|

40

|

18.5

|

1450

|

|

200QW250-15-18.5

|

200

|

250

|

15

|

|

|

|

200QW250-17-18.5

|

200

|

250

|

17

|

|

|

|

200QW300-10-18.5

|

200

|

300

|

10

|

|

|

|

300QW720-55-18.5

|

30

|

720

|

5.5

|

|

|

|

150QW130-30-22

|

150

|

130

|

30

|

22

|

980

|

|

150QW150-22-22

|

150

|

150

|

22

|

|

|

|

150QW200-22-22

|

150

|

200

|

22

|

|

|

|

200QW400-10-22

|

200

|

400

|

10

|

|

|

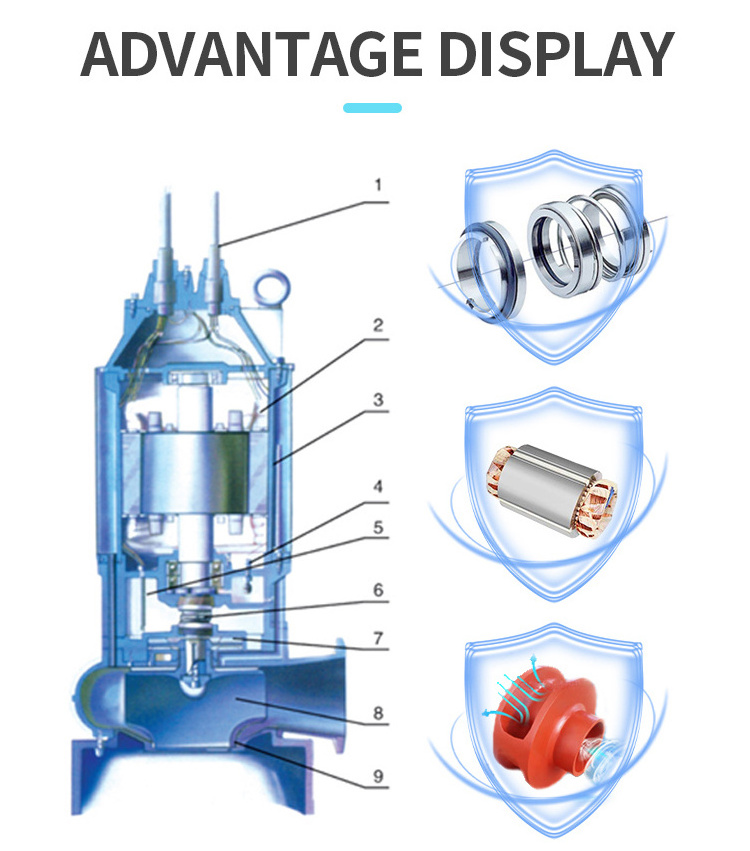

Details Images

1. The unique cable sealing design eliminates the hidden danger of cable water.

2. The stator is equipped with thermal protection element to ensure the motor running life.

3.18.5kW above the pump use external circulating water automatic cooling, to ensure that the electric pump in the lowest level of the state of safe operation.

4. The bottom ofthe motor cavity is equipped float switch to protect the mechanical seal of the motor side.

5. Oil and water probe is installed on the upper end of the oil chamber of the pump and motor to monitor and control the mechanical seal of the water pump side. Once water leaks, the control system will alarm for protection.

6.High-performance mechanical seal, sealing material for carbonized bustard.silicon carbide and hard alloy, prevent water into the motor, to ensure the safe and reliable operation of the motor.

7. The auxiliary impeller is used to balance the mechanical sealing external pressure to prevent water from entering the oil chamber, so as to extend the service life of the electric pump.

8.Impeller design is unique, large runner can pass through long fiber and dirt,anti-clogging, anti-winding, strong overflow energy.

9. There is a replaceable wear sleeve between the impeller and the lower end ofthe volute to keep the pump running with the best efficiency.

Simpler structure, easier repair

The original advantages remaining unchanged the casing is split into two parts. Inspection work only needs the upper casing to be dismounted,instead of the main distribution piping.

Hot Searches