- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Min 50KW

-

Dimension(L*W*H):

-

Min: L 5m*W 2m*H 6m / Customized

-

Roughness:

-

25-130um

-

blast cleaning speed:

-

0.5-4 m/min

-

Surface finish level:

-

SA2.5 to SA3.0

-

Blast chamber::

-

10mm shell &10mm Mn Alloy liner

-

Dust collector:

-

Cartridge/Bag type filter pulse reverse

-

Operate:

-

Fully Automatic Continuous blasting cleaning

-

PLC:

-

Siemens, Omron or famous brand in china

-

Spare parts:

-

Chrome&Mn Alloy Standard Part

-

Certification:

-

ISO, CE

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hezhi

-

Weight (KG):

-

1000 KG

-

Power:

-

Min 50KW

-

Dimension(L*W*H):

-

Min: L 5m*W 2m*H 6m / Customized

-

Roughness:

-

25-130um

-

blast cleaning speed:

-

0.5-4 m/min

-

Surface finish level:

-

SA2.5 to SA3.0

-

Blast chamber::

-

10mm shell &10mm Mn Alloy liner

-

Dust collector:

-

Cartridge/Bag type filter pulse reverse

-

Operate:

-

Fully Automatic Continuous blasting cleaning

-

PLC:

-

Siemens, Omron or famous brand in china

-

Spare parts:

-

Chrome&Mn Alloy Standard Part

-

Certification:

-

ISO, CE

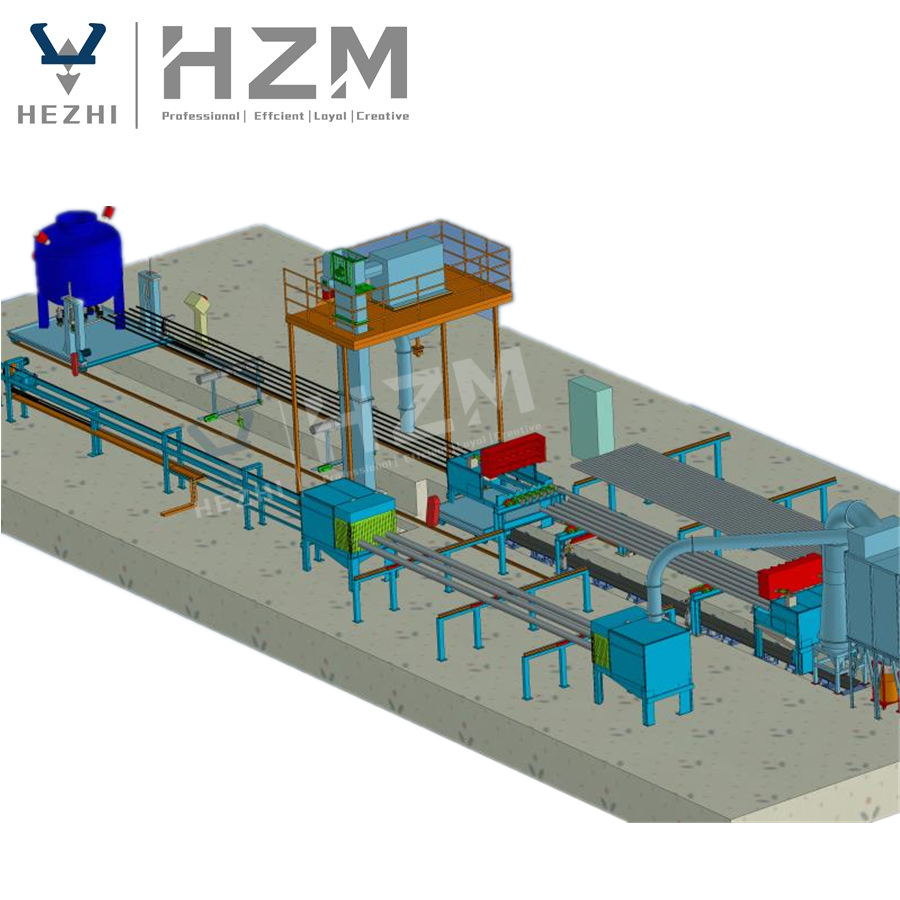

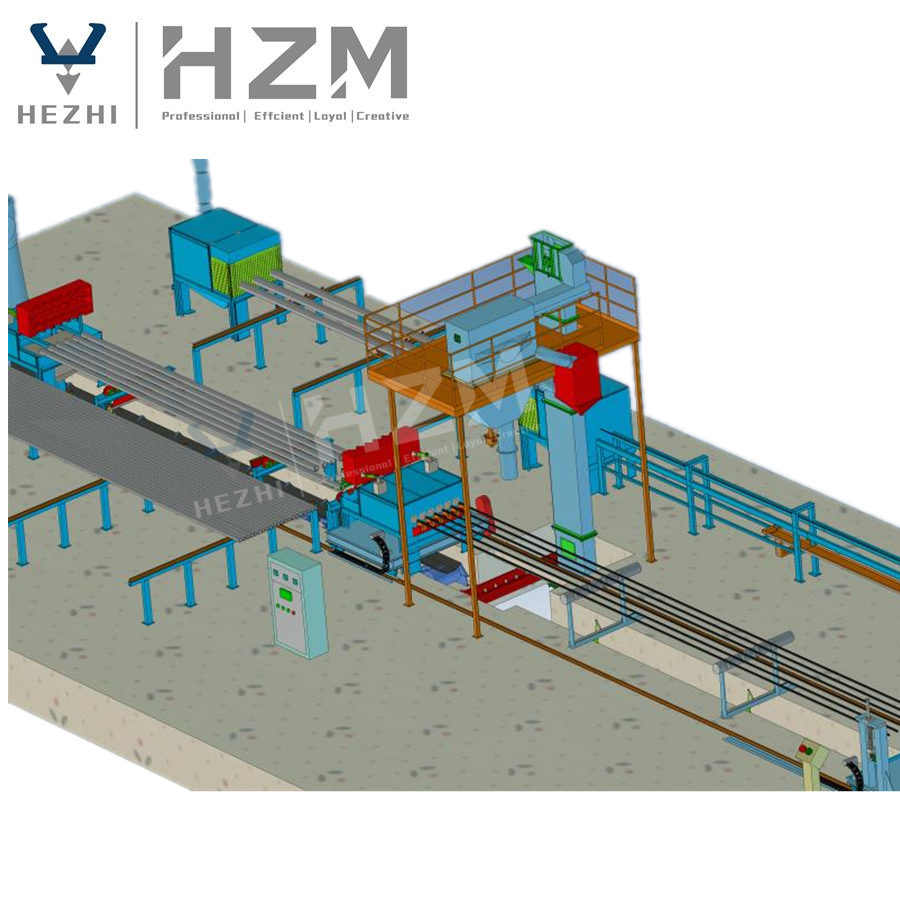

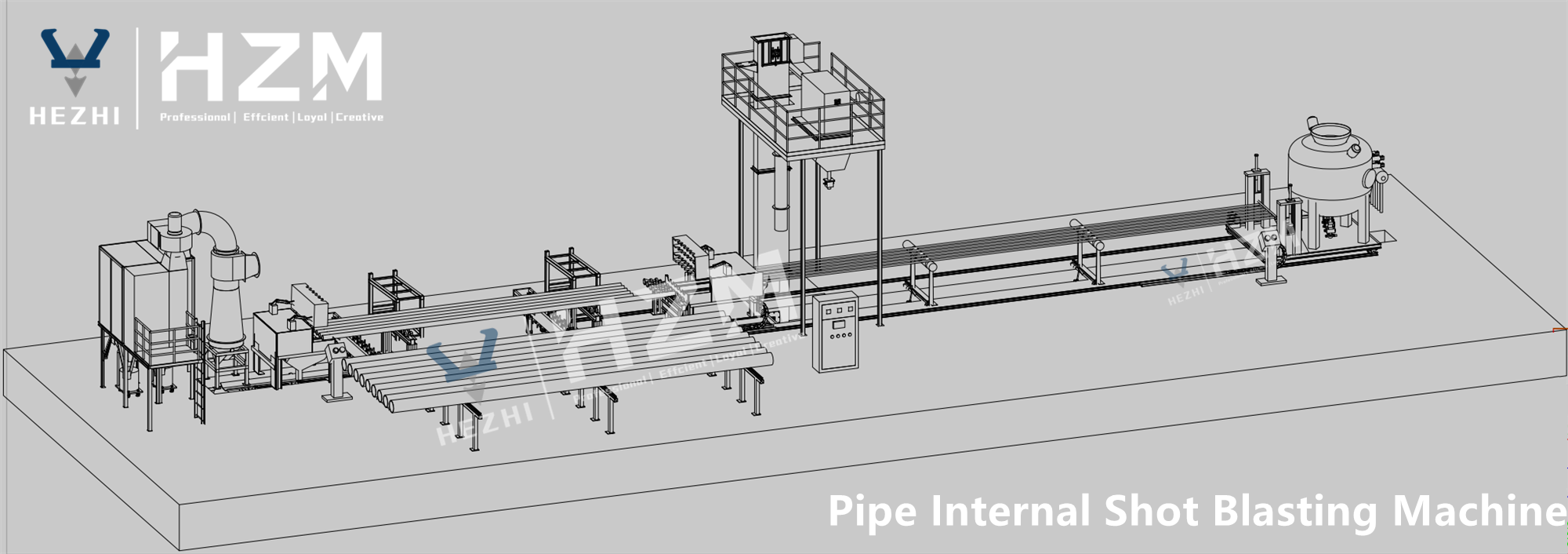

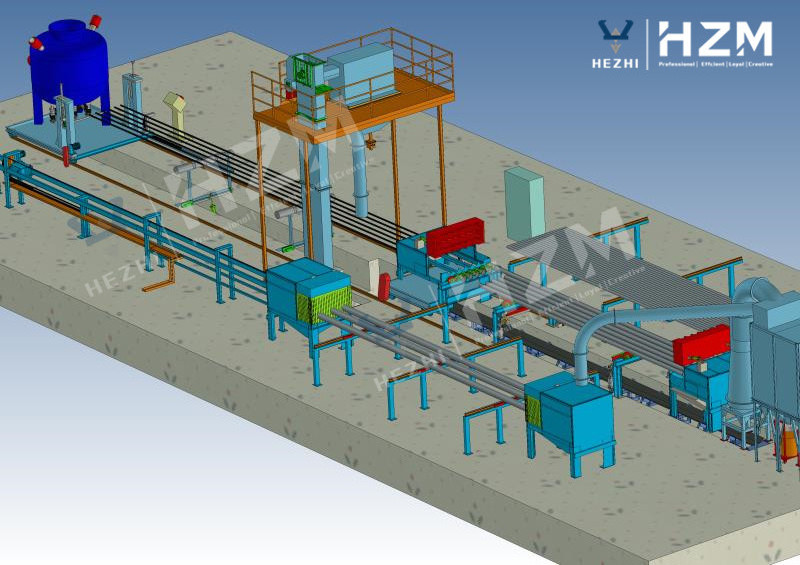

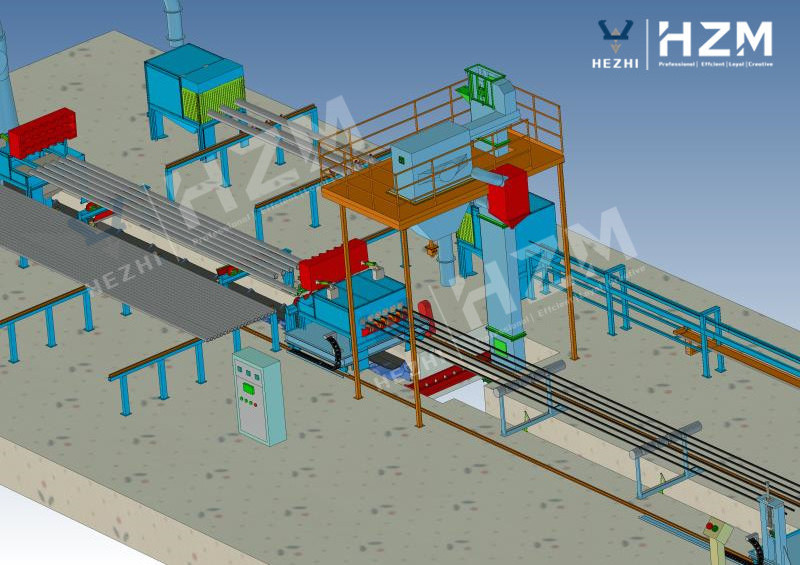

Steel Pipe Inner wall Sandblasting machine composed of pipe-rotating machine, grit-blasting trolley, grit-blasting head, grit-graying machine, grit-recycling line, specialized trolley for internal coating, grit-collecting box, grit separator, dust-removing system and operating platform, with many models to choose.

The trolley-type steel pipe special inner wall automatic sandblasting machine is a special equipment for cleaning the inner wall of pipes such as iron pipes, iron pipes, oil pipes, etc., which is specially designed to meet the specific process requirements of users. According to the different sizes of the pipe diameter, the automatic sand blasting and shot blasting cleaning machine is specially designed, equipped with an air compressor and a sand blasting tank, to achieve the purpose of automatic sand blast cleaning and rust removal.

Customized

|

Parameter

|

Cleaning Size

|

Cleaning Speed

|

Application and function

|

|

QGW100

|

50-300mm

|

2-10m/min

|

Pipe Outer wall cleaning

|

|

QGW720

|

159-720mm

|

2-6m/min

|

500mm

|

|

QGW1200

|

219-1016mm

|

1-6m/min

|

0.5-4m/min

|

|

QGW1500

|

325-1600mm

|

1-6m/min

|

8 pcs

|

|

QGW2800

|

1016-2800mm

|

1-2m/min

|

8 x125kg/s

|

|

QGN100

|

50-300mm

|

1-4m/min

|

Pipe Inner wall cleaning

|

|

QGN700

|

325-720mm

|

1-2m/min

|

293kw

|

|

QGN1000

|

720-1016mm

|

1-4m/min

|

|

|

QGN1500

|

1016-1500mm

|

1-4m/min

|

|

Q:

What is basting speed of roller conveyor shot blasting machine ?

A:

0.5-1.5 m per minute.

Q:

What is max weight of rollers of roller conveyor

shot blasting machine ?

A:

2 tons per 1 meter.

Q:

What kind of abrasives to be used for roller conveyor shot blasting machine ?

A:

Steel shots, steel grits or steel cut wire.

Q:

Is it necessary to dig pit for installation of roller conveyor shot blasting machine ?

A

:It depends on the rollers height and work piece size.

Q:

How to clean small work pieces shorter than 1 meter ?

A:

To make tooling on roller.

Q:

How many operators are needed to run roller conveyor shot blasting machine ?

A:

1 operator.

More questions please contact Anna, my phone No. is

0086 1995325 9235