- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars Machinery

-

Voltage:

-

380V 50HZ 3P

-

Dimension(L*W*H):

-

20m*4m*3.5m

-

Power (kW):

-

60

-

Weight:

-

4.5t

-

Product name:

-

PVC Corner Trim extrusion line making machine

-

Material:

-

PVC powder and additives

-

Color:

-

Customer Choice

-

Inverter:

-

ABB Brand

-

Product Type:

-

PVC profile,PVC board

-

Automatic Grade:

-

High Automation

-

Screw type:

-

Twin Conical Screw

-

Capacity:

-

100-400kg/h

-

Temperature control:

-

Japan RKC

-

Usage:

-

Room ceiling deceration

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

Russia, Morocco, Chile, Algeria

-

Certification:

-

CE IOS9001

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

132:1

-

Screw Speed (rpm):

-

150 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars Machinery

-

Voltage:

-

380V 50HZ 3P

-

Dimension(L*W*H):

-

20m*4m*3.5m

-

Power (kW):

-

60

-

Weight:

-

4.5t

-

Product name:

-

PVC Corner Trim extrusion line making machine

-

Material:

-

PVC powder and additives

-

Color:

-

Customer Choice

-

Inverter:

-

ABB Brand

-

Product Type:

-

PVC profile,PVC board

-

Automatic Grade:

-

High Automation

-

Screw type:

-

Twin Conical Screw

-

Capacity:

-

100-400kg/h

-

Temperature control:

-

Japan RKC

-

Usage:

-

Room ceiling deceration

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

Russia, Morocco, Chile, Algeria

-

Certification:

-

CE IOS9001

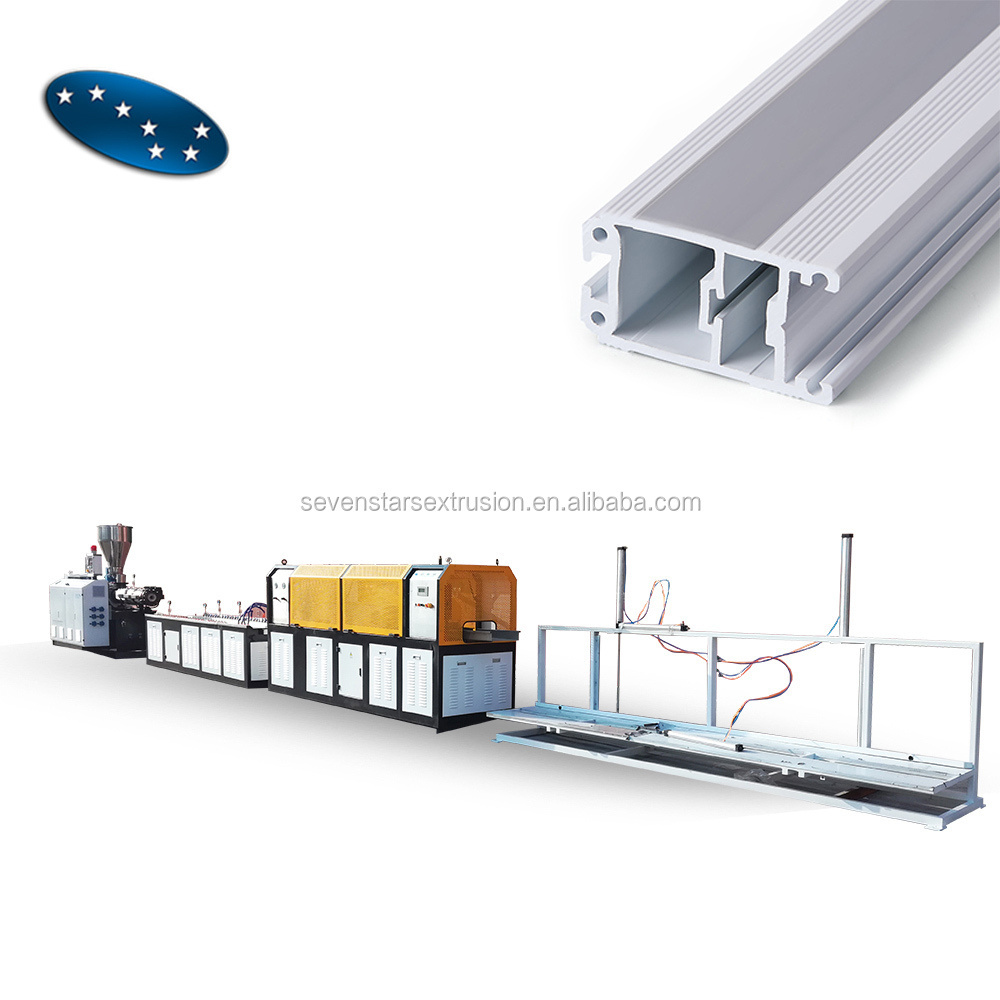

PVC Windows and doors profile Corner Trim extrusion line making machine

Product Description

plastic pvc profile

Production flow of PVC wall panel production line:

Material batching mixing→extruding→molding→vacuum calibrating and cooling→hauling→cutting→final PVC ceiling

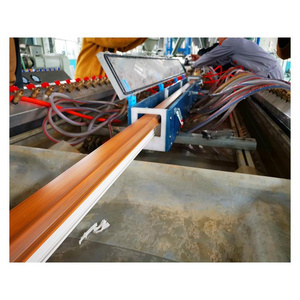

Surface treating ways:

- hot stamp printing

- two color printing

- lamination

Advantages of Wall Panel:

1.100% Water proof, Moisture proof

2.Wall Panel are 100% Damp proof

3.No splitting, cracking, warping or rotting.

4.No painting or varnishing

5.Wall Panel are Light in weight

6.Consistency in quality

7.Easy to install Time and labor saving

8.High durability

9.Wall Panels are Wide range color

10.High aesthetic appeal

11.Reusable

PVC ceiling panel extrusion production line used to produce PVC ceiling wall panel with different size, such as 200mm, 250m,300mm,400mm, 600mm and so on.

The main machines needed for PVC ceiling wall panel:

-PVC mixer

-PVC panel extrusion line

(Including autoloader, conical twin screw extruder, mould, vacuum calibration chamber, hauling machine, auto cutter- stacker)

- hot stamp printer or two color printing line or lamation

- PVC pipe crusher& PVC miller

- Air compressor

- Water chiller (optional)

Specification

|

Model

|

250

|

300

|

400

|

600

|

|

product width

|

160-250

|

160-300

|

250-400

|

400-600

|

|

Extruder

|

SJSZ48/118

|

SJSZ48/118

|

SJSZ55/120

|

SJSZ65/132

|

|

Capacity

|

60-120kg/h

|

60-120kg/h

|

100-160kg/h

|

150-220kg/h

|

Packing & Delivery

seaworthy packing for

PVC Window & Door & Windowsill Profile Production Line

Contact us

Hot Searches