- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

/

-

CrO Content (%):

-

/

-

SiC Content (%):

-

-/

-

Place of Origin:

-

Liaoning, China

-

colour:

-

black

-

raw material:

-

large crystal

-

addvantage:

-

ISO9001:2008

Quick Details

-

SiO2 Content (%):

-

-

-

Al2O3 Content (%):

-

/

-

MgO Content (%):

-

75%-78%

-

CaO Content (%):

-

/

-

CrO Content (%):

-

/

-

SiC Content (%):

-

-/

-

Place of Origin:

-

Liaoning, China

-

colour:

-

black

-

raw material:

-

large crystal

-

addvantage:

-

ISO9001:2008

Magnesia Carbon Bricks for LF

Specification :

|

Grade |

MgO (%) |

C (%) |

Apparent porosity (%) |

Bulk density (g/cm3) |

Cold crushing strength (MPa) |

Hot temperature Bending strength (MPa) ≥1400°C30mm |

|

MT -1 5 A |

≥7 6 |

≥ 1 5 |

≤4 |

≥ 3.02 |

≥40 |

≥12 |

Product features:

1. High refractoriness :1850°c:

2.High carbon content 15% ,excellent anti-oxidation,

3.Perfect thermal stability,resist the change of extreme hot and extreme cold ,super resistance for erosion and spall,

4 High strength :40 Mpa ,

5.Instructure density , low apparent ( less than 4%)

6.Strong performance for resist the brush;

7.High abrasion- resistance strength ,

8. perfect ability of anti-slag;

9. Difficult hydration,

10. can be used for long time.

Manufacture:

1.Choose the raw material :Use the large crystal , and high-purity graphite as raw materials;

2.Crushing the raw material into power :

2. Make the phenolic resin as the binder, add variety of additives

3.Mix the raw material evenly.

4.To form by high-pressure

5.To dry in the kiln under high temperature.

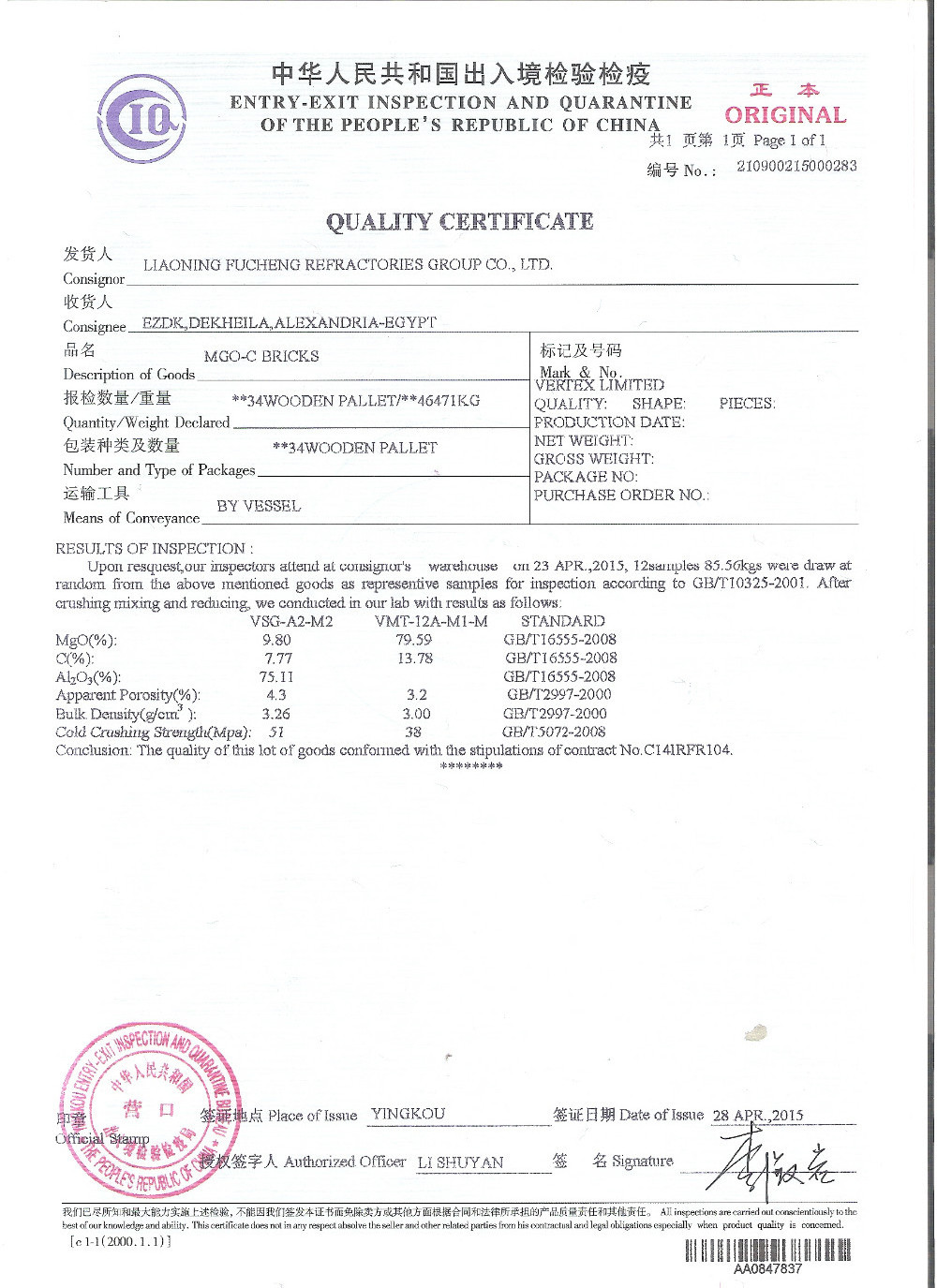

Quality control:

1.Examination for raw material :

2.Check the half-finished products:

3.Examination for every specification:

Used for LF furnace ;

1.Technical service :

(1). Design capacity:

We can d esign the whole furnace lining according to the measurement of furnace cover or the detailed specification that the customers supply ;if it is necessary we can we to investigate in the steel plants, and then design for the customer.

(2) .Manufacture :

We can manufacture Magnesia carbon bricks ,Alumina-Magnesia- carbon bricks ,tap hole ,clink bricks , most kinds of unshaped material.

(3). Construction capacity:

We have professional construction teams, we successfully finished lots of items of whole install for the customers from home and abroad so many years ,

(4). After-sale Service :

As starting up the operation ,we supply the scientific baking curve ,instruct the start up;

we will send a team which can follow the whole operate for converter , along with the detecting ;

We also will point one engineer to grasp the using situation in the steel plant ,in order to reflect the fact to our company.

2 . Feature Products :

(1) . MgO-C Bricks and Al-Mg-C Bricks

Used for Converter,EAF and Ladle .

(2) .Al 2O3 -SiC-C Bricks

Used for torpedo pot ;

(3).Magnesia Calcium bricks and Magnesia Chrome bricks

Used for Ladle

(4) .Unshaped refractory products.

Company information:

Liaoning Fucheng Refractories Group Co., Ltd is located in Nanlou Economic Development Zone, Dashiqiao City of southern Liaoning, well known for rich magnetite resources and superior geographical environment.

With registered capital of RMB 64.43 million, fixed assets of RMB 250 million, 1077 employees, and 213 engineers and technicians, our company covers an area of 537,000 square meters. Our annual production capacity: 150,000 tons of Magnesia carbon bricks and Alumina magnesia carbon bricks and 50,000 tons of Unshaped refractory products.

Our company

mainly produces Magnesia carbon bricks, Alumina magnesia carbon bricks for converters, EAF and ladles, non-carbon bricks for refining ladles, AL-SIC-C bricks for torpedo ladles, and various kinds of unshaped refractory materials such as repairing and gunning materials for converters, EAF and ladles. We also provide vibration moulding products such as permeable bricks for ladles, permeable nozzle seating bricks, nozzle seating bricks and prefabricated components.

Our company Cooperating with University of Science and Technology Beijing, we have established a refractory research base. We have also signed a long-term technical cooperation agreement with Krosaki Harima Corporation (a famous Japanese refractory company). University of Science and Technology Liaoning is also our technical support unit. In addition, we have also established a long-term strategic partnership with Beijing Shougang No. 2 Refractory Plant, a joint venture with a continuous casting production line in Qinhuangdao, to manufacture blast furnace stemming, castable and other products. We have developed into an integrating refractory enterprise integrating the research, deep processing, and trade of raw materials.

Our laboratory has a complete range of testing and inspection equipment. Our equipment can make raw materials, finished products, and testing and inspection, as well as develop new products.

We believe that science and technology is our guide. So we have gained domestic and foreign advanced technology, continuously improving product quality, technological content, and inherent stability, so as to improve production technology and constantly renovate our production equipment.

We provide a full range of technical services under the requirements of customers, according to the size and technology parameters of converter, EAF, and ladle. Our torpedo ladles are used for lining design, including the design of brick shape and material (computer graphics).

Our products are sold to more than 80 customers at home and abroad, mainly in Japan, the United States, Canada, Russia, South Korea, and India. There are 68 steel plants in Japan and 6 plants in the USA using our products, and we have earned good reputation from our customers.

Enterprise Idea:

An A Credit Rated Enterprise with the highest integrity.

Enterprise Principle:

More efficient, more productive and more competent.

Operation Principles:

1. As an A Credit Rated Enterprise, we try to be a large-scale enterprise with a large market share at home and abroad.

2. We improve our management system to be more standard and efficient, and become the top enterprise of manufacturing various refractory bricks for ladles.

Our Goals:

1. We do our best to foster the technical qualification of our employees, so our consumers are satisfied with each product and after-sales service we provide for them.

2. We are content with what we've done in our work.

3. We are ready to face the challenges and try our best to be excellent in refractory line.

Our company has attained International Quality System Certifications of ISO9001:2000 and ISO14001:2004