- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

5000 ml

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BS

-

Year:

-

new

-

Voltage:

-

220v/380V

-

Dimension(L*W*H):

-

1700*650*1700

-

Clamping Force (kN):

-

15

-

Power (kW):

-

14

-

Weight (KG):

-

950 KG

-

Cavity:

-

2-cavity

-

Bottle material:

-

PET PP

-

Function:

-

Semi Auto Blow Molding Machine

-

After-sales Service Provided:

-

Online Support

-

preform bases:

-

60 pcs

-

bottle max volume:

-

5000ml

-

nick diameter range:

-

15-80mm

-

bottle max diameter:

-

120mm

-

Advantages:

-

Easily Operation

-

Automatic:

-

Semi-autoamtic

Quick Details

-

Neck Diameter(mm):

-

15 mm

-

Max.Bottle Diameter(mm):

-

120 mm

-

Max.Bottle Height(mm):

-

400 mm

-

Bottle Volume(ml):

-

5000 ml

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BS

-

Year:

-

new

-

Voltage:

-

220v/380V

-

Dimension(L*W*H):

-

1700*650*1700

-

Clamping Force (kN):

-

15

-

Power (kW):

-

14

-

Weight (KG):

-

950 KG

-

Cavity:

-

2-cavity

-

Bottle material:

-

PET PP

-

Function:

-

Semi Auto Blow Molding Machine

-

After-sales Service Provided:

-

Online Support

-

preform bases:

-

60 pcs

-

bottle max volume:

-

5000ml

-

nick diameter range:

-

15-80mm

-

bottle max diameter:

-

120mm

-

Advantages:

-

Easily Operation

-

Automatic:

-

Semi-autoamtic

Specification

| Parameter | |

| Cavities | 2 |

| Small volume |

50ml |

| Max volume | 3000ml |

| Min mouth diameter | 15mm |

| Max mouth diameter | 80mm |

| Max bottle diameter | 120 |

| Max bottle height | 400 |

| Capacity per hour | 800-1200 bph |

| Operate pressure | 0.8-1.0 Mpa |

| Blowing pressure | 2-3 Mpa |

| Heating power | 14 kw |

| Blowing main machine weight | 720 kg |

| Heating machine weight | 280 kg |

| Blowing machine size | 1500*620*1700 |

| Heating machine size | 1750*600*1400 |

Description

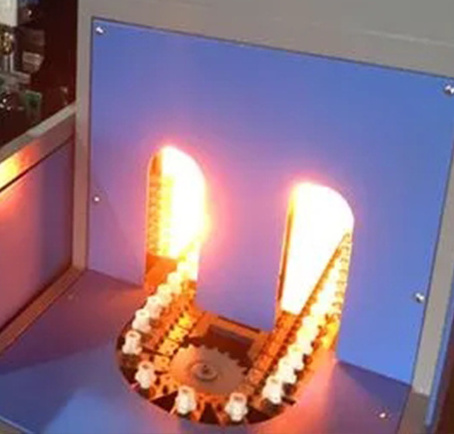

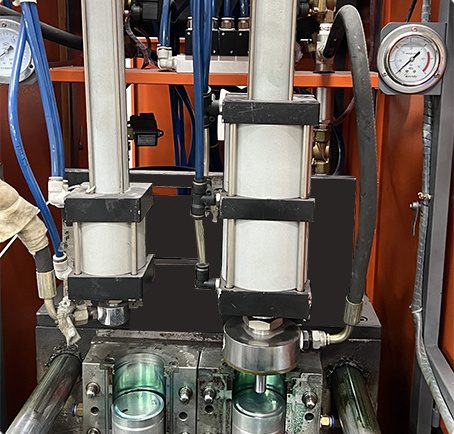

A semi-automatic bottle machine is a type of equipment used in the manufacturing of plastic bottles or containers. It is a machine that automates some steps of the process, but requires manual operation for other steps. This type of machine typically consists of a preform heating system, a mold clamping system, and a blowing system.

The preform heating system warms the plastic material to a certain temperature to make it pliable, allowing it to be molded into the desired shape. The mold clamping system holds the plastic material in place while it is molded. Finally, the blowing system inflates the plastic to the desired shape, creating the bottle or container.

The semi-automatic bottle machine is typically controlled by an operator who monitors the process to ensure the correct shape, size, and thickness of the bottle or container. After the bottle or container has been formed, the operator removes it from the mold and places it in a cooling rack.

Semi-automatic bottle machines offer advantages such as lower cost compared to fully automated systems, flexibility in production, and ease of operation. They are used in a variety of industries such as food and beverage, healthcare, and household products.