- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SAENYI

-

Model Number:

-

300/400/600*9MM

-

Material:

-

PVC+WOOD

-

Color:

-

CUSTOM-MADE

-

MOQ:

-

100SQM

-

Delivery:

-

FCL/LCL

-

Surface Texture:

-

PVC FILM

-

Installation:

-

CLICK

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Hotel,Villa,Apartment,Office Building

-

Design Style:

-

Modern,Traditional,Contemporary

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SAENYI

-

Model Number:

-

300/400/600*9MM

-

Material:

-

PVC+WOOD

-

Color:

-

CUSTOM-MADE

-

MOQ:

-

100SQM

-

Delivery:

-

FCL/LCL

-

Surface Texture:

-

PVC FILM

-

Installation:

-

CLICK

Related products

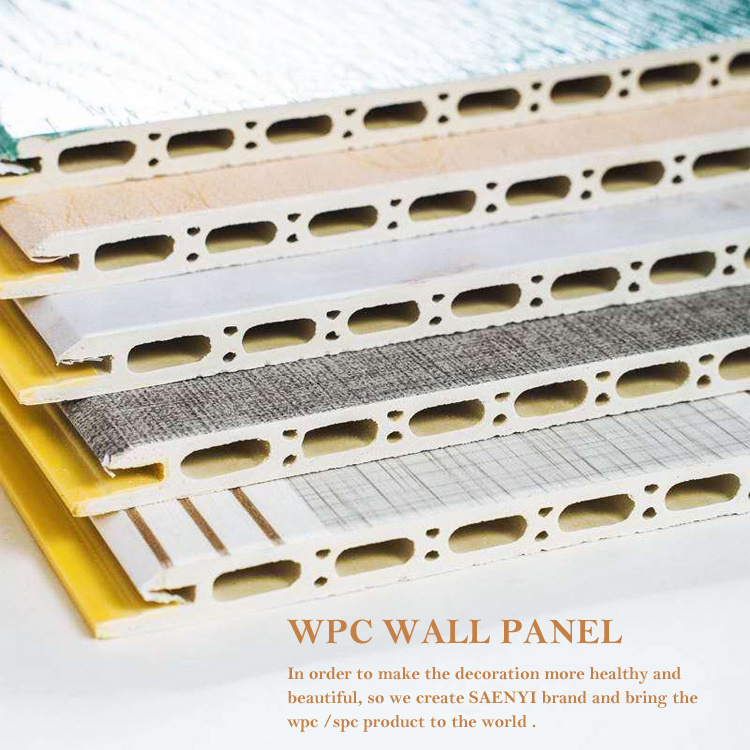

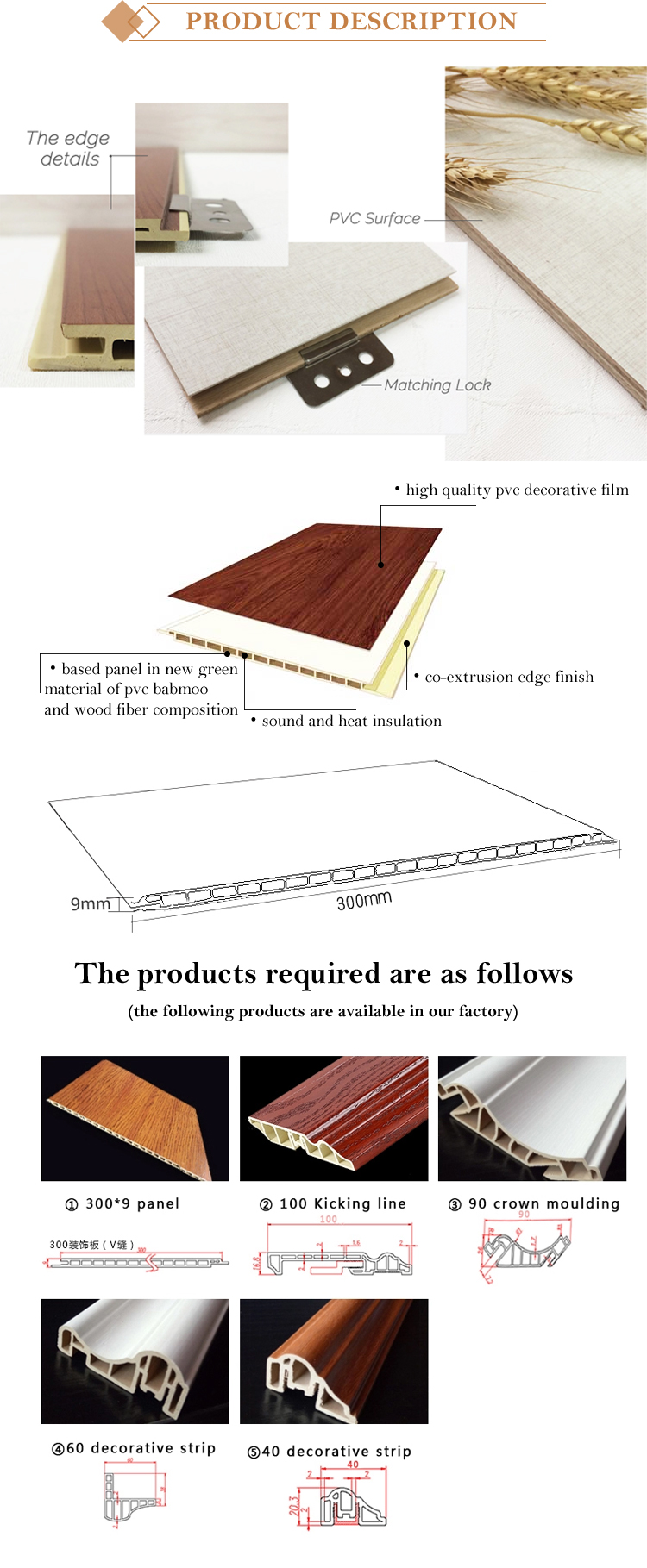

Product Description

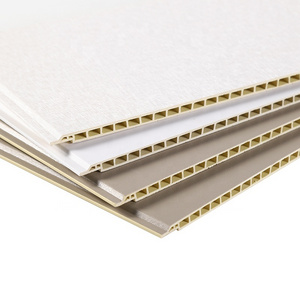

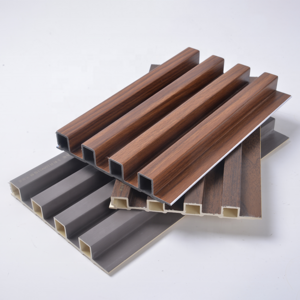

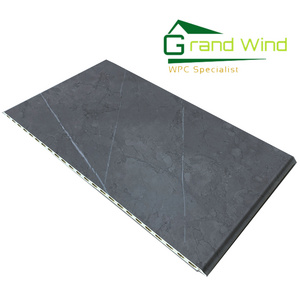

Specification

|

Name

|

Wpc Wall Panel

|

|

Material

|

Pvc+Wood

|

|

Color

|

Custom-Made

|

|

Surface Texture

|

Pvc Film

|

|

Application

|

Hotel,Villa,Apartment,Office Building,Hospital,School,Mall,Leisure Facilities and so on.

|

|

Place of Origin

|

Shandong,China

|

|

Installation

|

Click

|

|

Moq

|

10sqm

|

PRODUCTION PROCESS:

1. Wood power and pvc raw material are placed into the blender and mixed evenly.Pellets are then extruded out at a standard

temperature.

2. According to the formulas,different pellets are placed into blender and mixed evenly.

3. Profile will be then extruded out through a mold.After cooling down,profiles are solidified,forming the shape as the mold.

4. Cutting the standard size or according to the customer requirement.

5. Profile processing---grain surface,brushed surface,embossed surface,anti-UV surface.

6. Glue the film into the surface to protect it.

7. Package&deliver.

1. Wood power and pvc raw material are placed into the blender and mixed evenly.Pellets are then extruded out at a standard

temperature.

2. According to the formulas,different pellets are placed into blender and mixed evenly.

3. Profile will be then extruded out through a mold.After cooling down,profiles are solidified,forming the shape as the mold.

4. Cutting the standard size or according to the customer requirement.

5. Profile processing---grain surface,brushed surface,embossed surface,anti-UV surface.

6. Glue the film into the surface to protect it.

7. Package&deliver.

Hot Searches