- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/50HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ZXSMART

-

Dimension(L*W*H):

-

2200*750*1650mm

-

Weight:

-

300 KG

-

Machinery Capacity:

-

0-50BPM

-

Product name:

-

Horizontal Labeling Machine

-

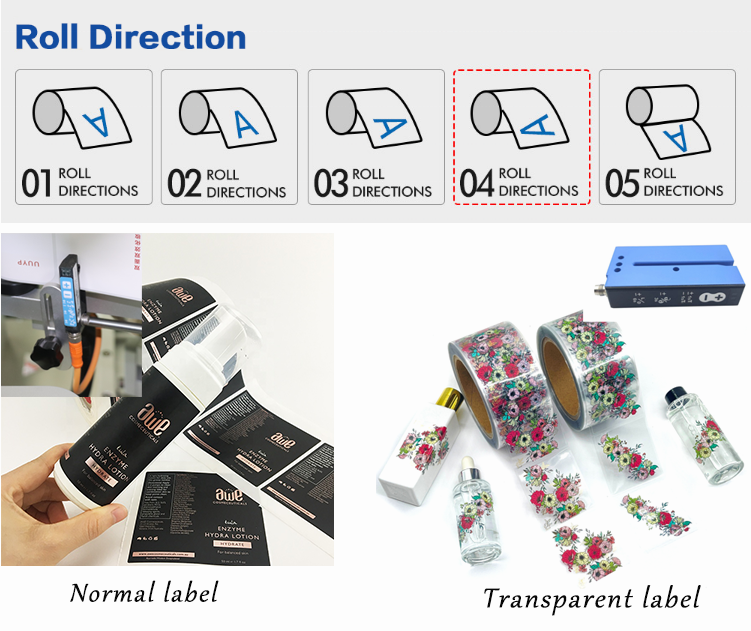

Applicable label length:

-

15mm ~ 100mm

-

Applicable label backing paper width:

-

15mm ~ 100mm

-

Applicable standard roll outer diameter:

-

280mm

-

Applicable standard roll inner diameter:

-

76mm

-

Labeling accuracy:

-

±1.0mm

-

Labeling speed:

-

0 ~ 50pcs / min (depending on the size of the bottle and the label)

-

Conveying speed:

-

5-20m/min

-

Bottle type:

-

Round Glass Pet small Bottle

-

Company type:

-

Integration of industry and trade

Quick Details

-

Application:

-

Food, Beverage, Commodity, Chemical, For flat surface labeling

-

Packaging Type:

-

Bottles

-

Packaging Material:

-

Plastic, Metal, Glass, Wood

-

Voltage:

-

220V/50HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ZXSMART

-

Dimension(L*W*H):

-

2200*750*1650mm

-

Weight:

-

300 KG

-

Machinery Capacity:

-

0-50BPM

-

Product name:

-

Horizontal Labeling Machine

-

Applicable label length:

-

15mm ~ 100mm

-

Applicable label backing paper width:

-

15mm ~ 100mm

-

Applicable standard roll outer diameter:

-

280mm

-

Applicable standard roll inner diameter:

-

76mm

-

Labeling accuracy:

-

±1.0mm

-

Labeling speed:

-

0 ~ 50pcs / min (depending on the size of the bottle and the label)

-

Conveying speed:

-

5-20m/min

-

Bottle type:

-

Round Glass Pet small Bottle

-

Company type:

-

Integration of industry and trade

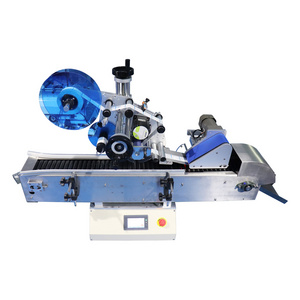

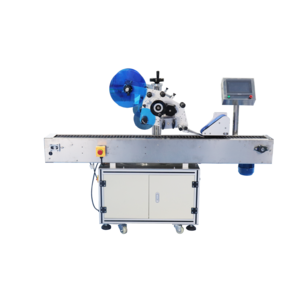

ZXSMART Automatic Horizontal Vial Oral Small Bottle Cosmetic Tube Labeling Machine

Products Description

Description

This machine is suitable for

labeling sticker on

cylindrical objects with small diameters

which are hard to stand up.

Horizontal

transmission

and labeling are used to increase stability and efficiency.

Widely used in

food,beverage,cosmetics industries.

Such as oral liquid bottle, smal bottle, ampoule, test tube, pen, etc.

This machine can be equipped with a date coder which can be used to code production date and production number.

Features

1.

The machine is suitable for full circle labeling or semicircle labeling on bottles.

2.The speed-regulating motor centrally controls the speed, start and stop of each speed-regulating motor.

3.Full English or customer’s local language touch screen, real-time control, all-round adjustment, and clear parameters.

4.Parameter settings and statistical data will be retained during data power outage to avoid data loss during unexpected shutdown.

5.Once a malfunction occurs during the labeling process, the machine's red light will light up and it will automatically stop and alarm.

|

Technical Parameter

|

|

|

|

Model

|

ZX-HBLM

|

|

|

Suitable label

|

L: 15-100mm; W: 15-100mm

|

|

|

Suitable bottle

|

Diameter: 10-30mm

|

|

|

Suitable label roll

|

Inner Diameter: 76mm

Outer diameter: 280mm

|

|

|

Labeling precision

|

±1mm

|

|

|

Labeling speed

|

0-300 pcs/min

|

|

|

Conveyor moving speed

|

5-20 m/min

|

|

|

Power

|

220V, 50Hz, 1500W

|

|

|

Net weight

|

180KG

|

|

|

Machine size

|

2200*750*1450mm(L*W*H)

|

|

Details Images

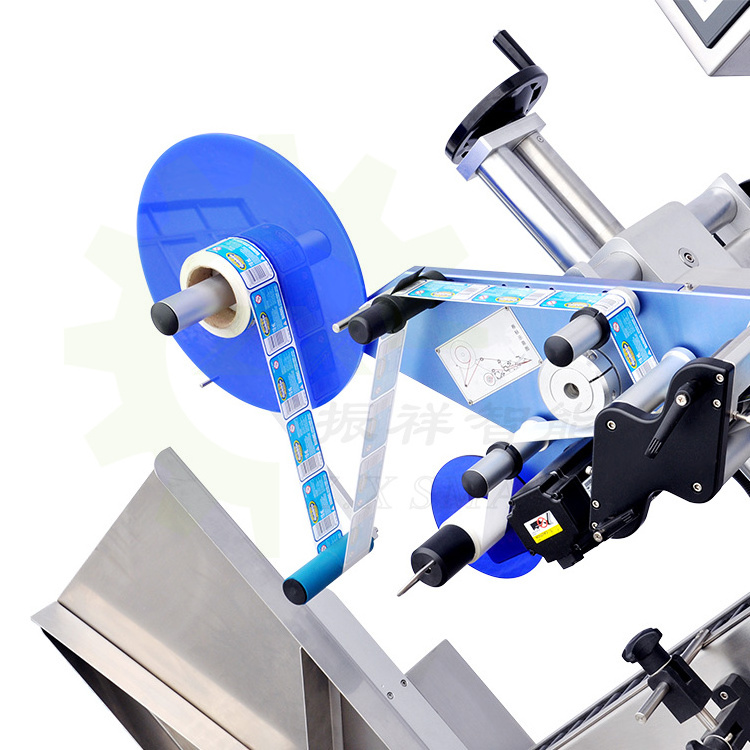

Labeling station

The sponge belt on the left presses the bottle to ensure labeling stablility and the label coverage effect. The label separating board on the right will automatically provide the label and separate it off when the sensor detects the bottle. If there is no bottle, no label will be applied.

Label fixing and sending station

Equipped with imported acrylic label fixing plate and sponge belt at the corners to prevent label damage

and jamming.

The large handwheel can be easily adjusted

, and the servo motor drives the entire work station, which is stable and high-speed.

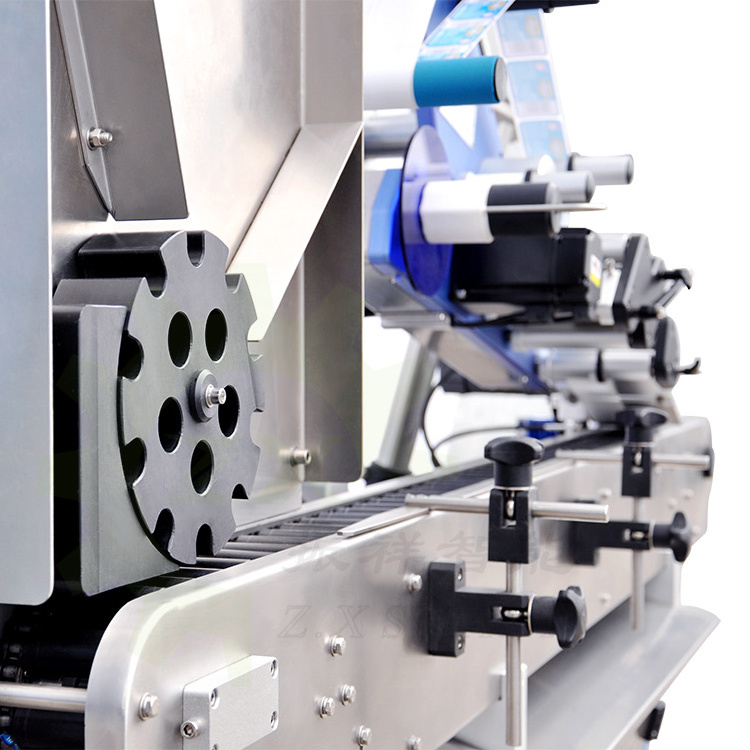

Bottle sorting and feeding station

The rationally designed bottle sorting station sends bottles to the conveyor belt through a rotating plate, making production orderly and improving work efficiency. The visual structure allows you to check whether there are any missing bottles at any time.

Coding machine

This machine can be equipped with a date coder to

reduce production process and save production cost.

Can be coded horizontally and vertically, with clear printed handwriting, and the coding speed matches the labeling speed simultaneously.

SIEMENS Touch screen

Imported

high-quality intelligent operation touch screen

can adjust the parameters of the whole machine to maximizing the intelligence and simplicity of operation.

Recommend Products

Company Description

The Packing And Shipping

Our Service

FAQ

Q:What industry is your product suitable for?

A:The product line we develop and produce is suitable for the production of various, liquid, paste, powder, solid products. The specific product materials, functions, specifications and production capacity can be customized according to customers' products and requirements.

Q: What if the machine fails during use?

A:Our products will be carefully inspected and ensured before delivery, and we will provide the correct instructions for use of the products; in addition, our products support lifetime warranty warranty service, if there are any questions during the use of the product, please consult our work. personnel.

Q: When can I get my machine after paid?

A: The delivery time of a production line is generally 60 days; the product is about 15-30 days.We will deliver it on time as the date we agreed both side.

Q: How can I install my machine when it arrives?

A: We will provide installation videos and tutorials, or send our engineer to your side ASAP you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q:What payment do you accept?

A: We generally use T/T or L/C, and we can negotiate the payment method.

A:The product line we develop and produce is suitable for the production of various, liquid, paste, powder, solid products. The specific product materials, functions, specifications and production capacity can be customized according to customers' products and requirements.

Q: What if the machine fails during use?

A:Our products will be carefully inspected and ensured before delivery, and we will provide the correct instructions for use of the products; in addition, our products support lifetime warranty warranty service, if there are any questions during the use of the product, please consult our work. personnel.

Q: When can I get my machine after paid?

A: The delivery time of a production line is generally 60 days; the product is about 15-30 days.We will deliver it on time as the date we agreed both side.

Q: How can I install my machine when it arrives?

A: We will provide installation videos and tutorials, or send our engineer to your side ASAP you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q:What payment do you accept?

A: We generally use T/T or L/C, and we can negotiate the payment method.

Hot Searches