- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

1000x1900x1600mm

-

Weight:

-

1000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

material:

-

paper, film, non woven fabric,pe,opp,napkin

-

control:

-

inverter control

-

winding:

-

double or single winding

-

ink transfer way:

-

Metal anilox roller

-

color:

-

one colors

-

shaft:

-

air shaft

-

tension:

-

auto tension

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LISHENG

-

Voltage:

-

220v-380v(design for customer)

-

Dimensions(L*W*H):

-

1000x1900x1600mm

-

Weight:

-

1000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

material:

-

paper, film, non woven fabric,pe,opp,napkin

-

control:

-

inverter control

-

winding:

-

double or single winding

-

ink transfer way:

-

Metal anilox roller

-

color:

-

one colors

-

shaft:

-

air shaft

-

tension:

-

auto tension

Product Description

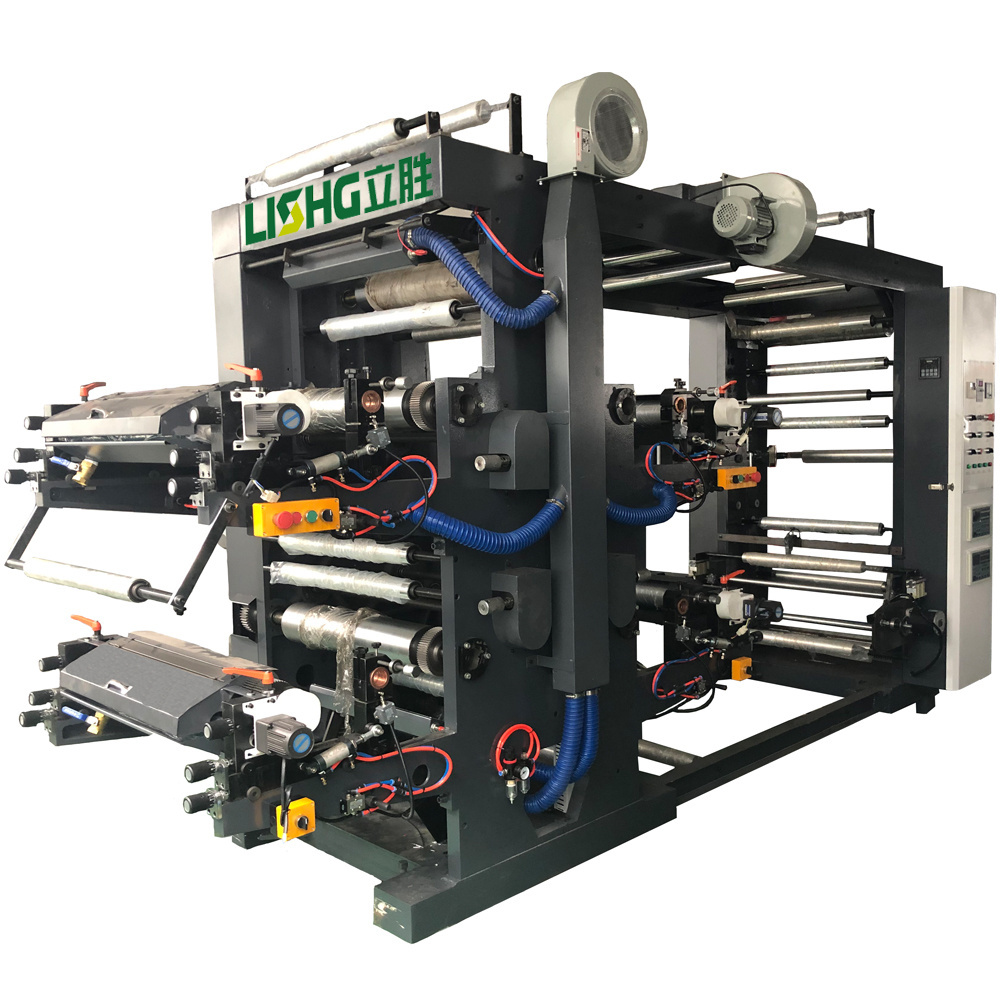

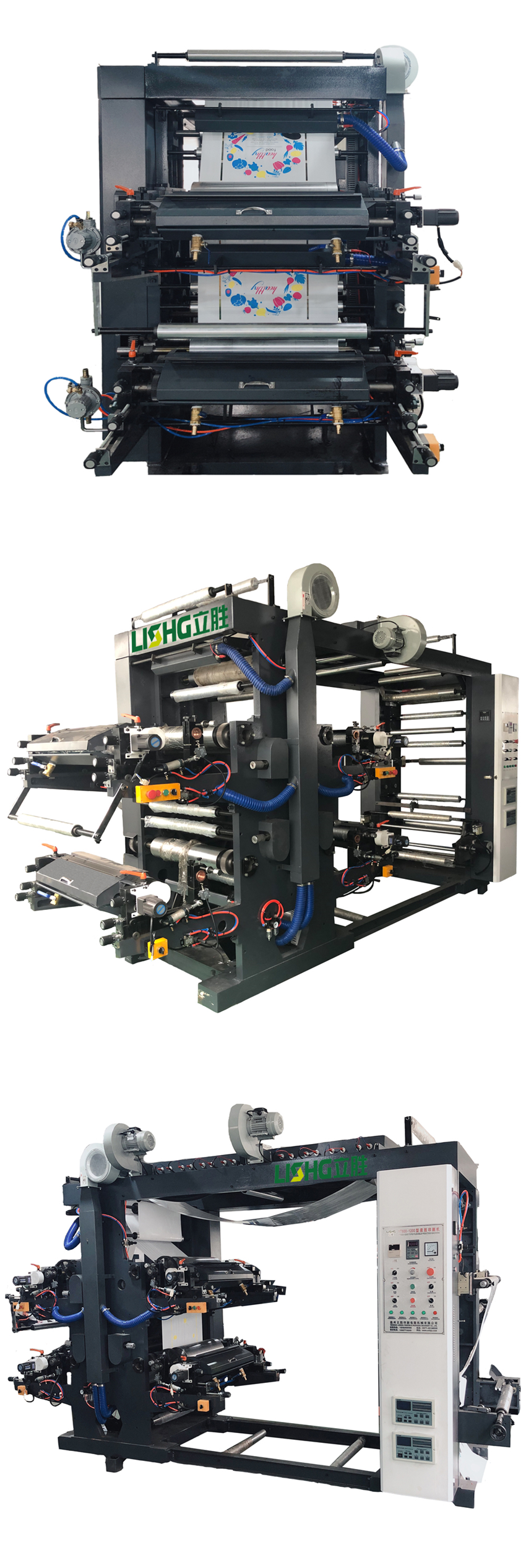

This central impression (central drum)flexographic printing machine is suitable for printing such packing materials as polyethylene, polyethylene plastic bag, leather, glass paper and roll paper etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

|

Model

|

YT series

|

|

Material width

|

200~1600mm

|

|

Printing width

|

100~1560mm

|

|

Thickness of plate

|

1.14mm.1.7mm 2.28mm.2.84mm. 3.94mm

Customized is available |

|

Printing length

|

Standard is 400mm,

Customized is available from 300-1000mm |

|

Maximum machine speed

|

80m/min

|

|

Printing speed

|

50m/min

|

|

Register precision

|

≤0.3mm

|

|

Structure type

|

Stack

|

|

Gear module

|

1.5mm

|

|

Heating method

|

Electricity heating

|

|

Max. oven temp.

|

Max. 80℃(room temp. 20℃)

|

|

Web fixing method for un/rewinder

|

Safety chuck+ Air expanding shaft

|

|

Adhesive tape thickness for stick printing cylinder

|

0.38mm

|

|

SUITABLE MATERIAL:

|

|

|

|

|

||||

|

Paper series: Kraft paper:40-350gsm, single-sided coated paper:30-350gsm, copy paper:15-350gsm, firecrackers and paper:40-350gsm,

paper money and incense:25-350gsm, silicone paper:50-350gsm, coated paper:30-350gsm, dust-free paper:25-350gsm, release paper:40-350gsm, composite paper:30-350gsm, thermal sensitive paper:30-350gsm... |

|

|

|

|

||||

|

Plastic film series: PVC:10-120g/㎡, OPP:10-120g/㎡, PE:10-120g/㎡, PET:10-120g/㎡, CPP:10-120g/㎡...

|

|

|

|

|

||||

|

Woven:15-120g/㎡, Weave fabric:15-500g/㎡, Toilet paper, leather...

|

|

|

|

|

||||

|

Specific details welcome consultation

|

|

|

|

|

||||

Key components

Air shaft

Tight to material ,flat material , better printing

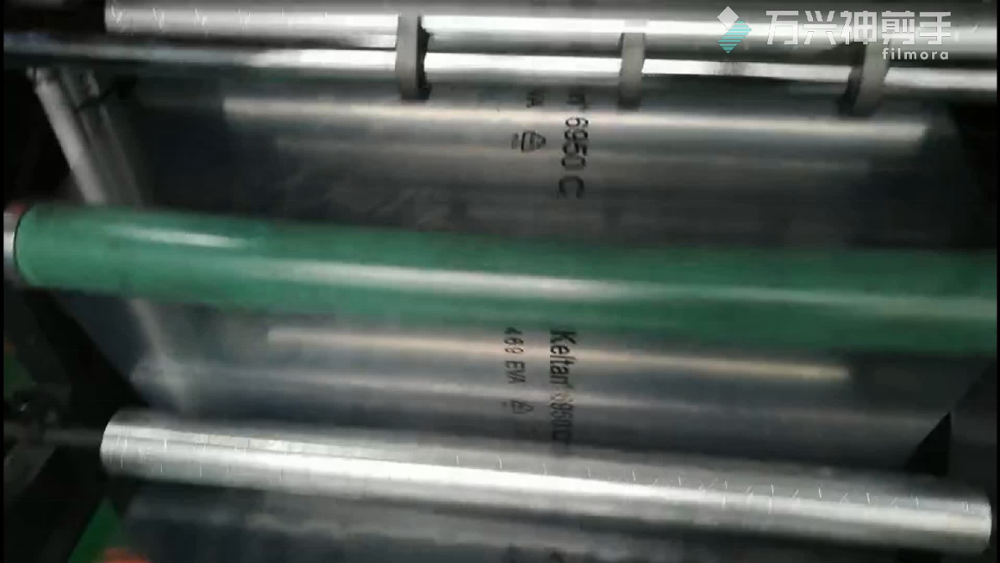

Metal Anilox roller

Carry the inks to the plate cylinder.

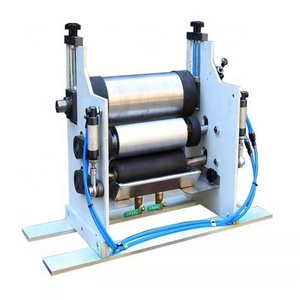

Big roller friction rewinding type

Rewinding the material more tight and keep in line. Special for leather

Import Auto tension control & magnetic power (2 set )

Control un&rewind parts balance material both side.

Ultrasonic Web guide (1set)

Swift tracking print photo .

Auto hydraulic loading&unloading for unwinding

It is easy to transport and loading material.

Sample pictures

Related Products

Certifications

After Sales Service

After sale service

Can arrange engineer come to install the machine and training worker, but customer need pay the charges, include flight tickets cost, boarding and lodge cost, salary 100USD/day.

Exhibition

FAQ

1.Are You a Factory or Trading Company?

-We are a factory, with 20 years experience on machines, our products sell very well all over the world.

2.Where is your factory located? How can I visit there?

-Our factory is located in Ruian Zhejing China. The nearest airport is Wenzhou airport. It's about 40 minutes by plane from Shanghai (5 hours by train). All our cliens, from home or abroad, are warmly welcomed to visit us.

3.What can the machine print on?

-Our machine is multifunction, can do roll to roll printing, such as paper, plastic, woven,nonwoven and so on . Surely, you can send us your products, and we'll offer you the proper machine.

4.Can I get some samples? How can I get it ?

-Yes, we can send you some free sample, but you are reponsable for delivery charages of TNT or DHL.

5.How about the after service?

-We can arrange engineers to service overseas.

6.Why choose Lisheng Machinery?

-We are one of leaders in this field(in China). Our high-quality products and service enabled us to expand our market from china to more than 60 countries.

7.I need a quotation/how much is your price?

-Please tell us your material,the width of your material,and how many color do you need? Then we will know which machine is suitable for you and suggest the right machie for you.

8.Waht's your delivery time?

-Usually finish the production within 30 days after we confirm to receive the 30% advanced payment.Actually need to check according to our stock & production plan.

-Usually finish the production within 30 days after we confirm to receive the 30% advanced payment.Actually need to check according to our stock & production plan.

9.How long is your machine's warranty period?

-All our machine have one year guarantee, starting from finished installation.

10.How would we do if the parts broken within warranty?

-We would express the free replacement partswithin the warranty date.

Hot Searches