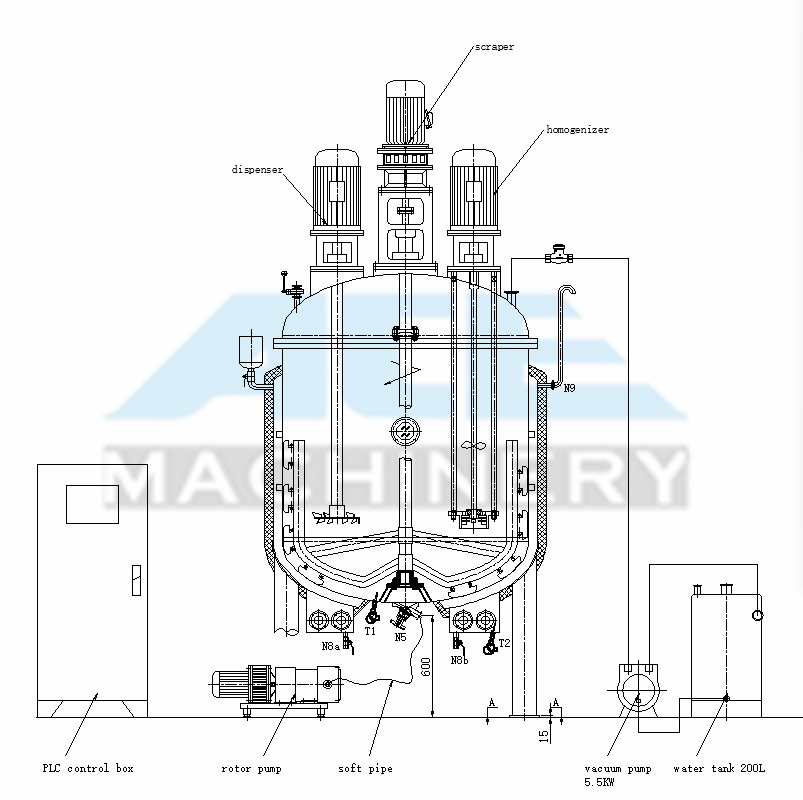

This series is the most advanced blending equipment in fields of Chemical, pharmaceutical, food, etc. When the high-speed super-fine emulsification paddle works, it throws the materials in the center of rotor to stator at a high speed,then through tooth clearance of stator,and shearing,collision and crushing between rotor and stator,the super-fine emulsification is realized. therefore,it is an integrated equipment comprising functions such as blending,emulsifying,homogenizing,solving and crushing.

- Product Details

- {{item.text}}

Quick Details

-

Motor:

-

Domestic/ABB/Siemens

-

Material:

-

Stainless Steel 304 / SUS316L

-

Structure:

-

single/double jacket/three layers

-

Mixer type:

-

Agitator,homogenizer,paddle,frame,anchor,scraper with stirrer

-

Jacket:

-

Cooling and heating jacket avaible

-

Usage:

-

Produce Lipstick

-

Mixing Speed:

-

0-65r/min

-

Homogenizer Speed:

-

0-3600 RPM

-

keyword:

-

Vacuum Emulsifying Mixer

-

Application scope:

-

Nail Polish

Quick Details

-

Brand Name:

-

ACE

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

1000

-

Motor:

-

Domestic/ABB/Siemens

-

Material:

-

Stainless Steel 304 / SUS316L

-

Structure:

-

single/double jacket/three layers

-

Mixer type:

-

Agitator,homogenizer,paddle,frame,anchor,scraper with stirrer

-

Jacket:

-

Cooling and heating jacket avaible

-

Usage:

-

Produce Lipstick

-

Mixing Speed:

-

0-65r/min

-

Homogenizer Speed:

-

0-3600 RPM

-

keyword:

-

Vacuum Emulsifying Mixer

-

Application scope:

-

Nail Polish

Automatic Vacuum Emulsifying Mixer Lipstick Mixing Cosmetic Cream Making Machine

Custom Made 50L- 10,000L H

igh Shear Mixing Tank

, 20 Years Of Experience. Reasonable Price And Best Service,

15-30 Day Fast Delivery.Please Contact us for the offer.

Video

Products Description

Mixing tanks come in various sizes and can be used in a wide range of industries.

We are a manufacturer of stainless steel mixing tanks designed to fit your products and processes.

We are a manufacturer of stainless steel mixing tanks designed to fit your products and processes.

Description:

|

We can customize the equipment according to customer requirements.

|

|

|

|

Tank Volume

|

From 50L to 30,000L

|

|

|

Material

|

304 or 316 Stainless steel

|

|

|

Insulation

|

Single layer or with insulation

|

|

|

Top Head type

|

Dish top, Open lid top, Flat top

|

|

|

Bottom type

|

Dish bottom, Conical bottom, Flat bottom

|

|

|

Agitator type |

impeller, Anchor , Turbine , High shear, magnetic mixer, Anchor mixer with scraper

|

|

|

|

magnetic mixer, Anchor mixer with scraper

|

|

|

Inside Finsh

|

Mirror polished Ra<0.4um

|

|

|

Outside Finish

|

2B or Satin Finish

|

|

|

Vacuum Emulsifying Mixer

|

|

|

|

Vacuum Emulsifying Mixer Lipstick Mixing Machine Cosmetic Cream Making Machine for sale

|

|

|

|

Lipstick Mixing Machine

|

|

|

Capacity&Characteristic of stainless steel mixing equipment

* Contact part : SUS316L or SUS304

* Function : heating, blending, homogenizing

* Mixing system : frame scraper agitator mixer and high shear homogenizer mixer

* Heating system : jacket heating / running water cooling

* Movable design and simple to operate

Applicable Products.

1. Cosmetics industry: skin care cream, shaving cream, shampoo, toothpaste, cold cream, cold sun cream, facial cleanser, nutrition dense, detergent, shampoo, hair cream, conditioner, serum, moisturizing cream, Hand cream and so on.

2. Daily chemical industry:Laundry liquid production, hand sanitizer, toilet net, car glass water.

3. Pharmaceutical Industry:Latex, emulsion, ointment (ointment), oral syrup, oral liquid and the like.

4. Food Industry:Sauces, cheese, nutritional liquid, baby food, chocolate, sugar and so on.

5. Chemical Industry:Latex, Sauce, saponified products, paints, coatings, resins, adhesives, lubricants and so on.

Configuration:

1. Quick opening manhole.

2. Various types of CIP cleaners.

3. Sanitary ventilation hood to defend against flies insects.

4. Adjustable triangular bracket.

5. Detachable feeding tubes.

6. Thermometer (According to the customer’s requirements).

7. Ladder (According to the customer’s requirements).

8. Advancing side blender

9. Level meter and level controller (According to the customer’s requirements).

10. Anti-vortex plate.

Standard mixing tanks or tailor-made for your product and process

We understand that every mixing tank is different. Therefor, we design our tanks tailor-made for you, so you can be sure that the tank will suit to your product and process best.

Options we can include into your tank are:

* Tillable

*Fully integrated control panel

*Heated and/or cooled

*Agitators

*Load cells

*Level switches

*Cleaning options

*Skid mounted

Features:

1. Inner tank body, jacket and outer layer, with thermal insulation material filled in between.

2. Materials are all sanitary stainless steel.

3. User-friendly design ,easy to operate.

4. Transition area of interior wall on tank adopts arc for transition to ensure no dead comer of sanitation.

Agitator design and fabrication:

In addition to tanks, We also make its own agitators. This way you have one point of contact for the entire tank concept. Agitators that we design and produce are:

*Gate agitator

*Anchor agitator

*Scraping agitator

*Propeller agitator

*Bottom driven agitator

*Dispersing disk

*Rotor/stator

*Screw agitator

*Combination of agitators

*High shear mixer

*Turbo mixer

*Side entry agitator

*Static mixer

*External homogenizer

...

|

Model

|

Effective

|

Stirring power and speed

|

|

Homogeneous power and speed

|

|

Heating power

|

|

|||||||

|

|

Capacity

|

KW

|

R/MIN

|

KW

|

R/MIN

|

Electric heating

|

Steam heating

|

|||||||

|

ACE-50

|

50

|

0.75

|

0-65

|

3

|

3600

|

6KW

|

selected according to need

|

|||||||

|

ACE-100

|

100

|

1.5

|

0-65

|

1.5

|

3600

|

12KW

|

|

|||||||

|

ACE-150

|

150

|

1.5

|

0-65

|

1.5

|

3600

|

12KW

|

|

|||||||

|

ACE-200

|

200

|

1.5

|

0-65

|

3

|

3600

|

18KW

|

|

|||||||

|

ACE-300

|

300

|

1.5

|

0-65

|

3

|

3600

|

18KW

|

|

|||||||

|

ACE-500

|

500

|

2.2

|

0-65

|

4

|

3600

|

27KW

|

|

|||||||

|

ACE-1000

|

1000

|

4

|

0-65

|

7.5

|

3600

|

36KW

|

|

|||||||

|

ACE-1500

|

1500

|

4

|

0-65

|

11

|

3600

|

45KW

|

|

|||||||

|

ACE-2000

|

2000

|

5.5

|

0-65

|

11

|

3600

|

Recommend steam heating

|

|

|||||||

|

ACE-3000

|

3000

|

7.5

|

0-65

|

15

|

3600

|

|

|

|||||||

|

ACE-5000

|

5000

|

11

|

0-65

|

22

|

3600

|

|

|

|||||||

|

The parameters for reference ONLY, all the machines can be customized accordingly.

|

|

|

|

|

|

|

|

|||||||

1, Bottom magnetic agitator with propeller impeller, speed from 50-400rpm or 50-800rpm. This kind of agitator is mixing thin viscosity, such as eye drop, injection, CIP liquid, water, etc.

2, Top mechanical agitator with propeller impeller, speed at fix 71rpm or adjustable 20-200rpm or special requirement. This kind of agitator is mixing syrup, injection, blood, oral liquid, culture media, etc.

3, Top mechanical agitator with anchor or frame impeller, speed is from 10-70rpm. It is mixing higher viscosity, such as sediment or viscosity oral liquid, etc.

4, Top emulsification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. This kind of agitator is mixing most high viscosity, such as suspension, oil, fat emulsification, etc.

5, Bottom emulsification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. This kind of agitator is mixing most high viscosity, such as suspension, oil, fat emulsification, etc.

We have more than one hundred different types of mixers to meet your product process.

Details Images

Packaging & Shipping

We are experienced in the whole packing and shipping process,and we will be responsible for any damage made during shipping and send clients replacements for free.

* Sufficient inner protection with different materials, including bubble bag, foam board and others.

* Qualified wooden package or carton for different products or as customer require

* Strict packing process to ensure the safety and completeness of the goods

Products Description

FAQ

|

Q

|

Are you trade or manufacturer?

|

|

|

|

|||

|

A

|

We are a factory with an international sales company specialized in support for global distributors.

|

|

|

|

|||

|

Q

|

Can you provide instant technical consulting services?

|

|

|

|

|||

|

A

|

We are able to discuss technical details and offer suggestions over the phone in English.

You can get the answers in minutes, instead of days. |

|

|

|

|||

|

Q

|

What's the difference between Ready-To-Ship and Customized products?

|

|

|

|

|||

|

A

|

Some of RTS standard products are in stock and ready to ship in 2-3 days.

We can also quick design and make the drawings for customer requirements, then begin the production. |

|

|

|

|||

|

Q

|

What is the payment terms?

|

|

|

|

|||

|

A

|

We accept Alibaba Trade Assurance Order, also can T/T and L/C.

|

|

|

|

|||

|

Q

|

How to choose the shipment way?

|

|

|

|

|||

|

A

|

It is according to the order quantity, delivery time, costs and customs policy etc. (Or decide by customers)

|

|

|

|

|||

|

Q

|

How about the after-sales service?

|

|

|

|

|||

|

A

|

Fast after-sales support. Our products have a one-year warranty and free permanent consulting services.

|

|

|

|

|||

Contact Us

Hot Searches