- Product Details

- {{item.text}}

Quick Details

-

Internal Dimensions(l x W x H)(mm):

-

12000x2273x2294

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CIMIC

-

Standard:

-

T11 IMDG, US DOT C

-

MAWP:

-

4bar

-

VESSEL DESIGN TEMP.:

-

-40℃ to 130℃.

-

CLASSIFICATION:

-

Bureau Veritas or LR

-

MATERIAL:

-

SA516 Gr 70 Carbon steel .

-

SAFETY RELIEF VALVE:

-

3" flanged 4.4 bar

-

MANLID:

-

1 x stainless steel, 500mm

-

TOP DISCHARGE PROVISION:

-

1 x 3" recessed tank pad

-

AIR INLET:

-

1.5" ball valve

-

Certification:

-

ISO9001

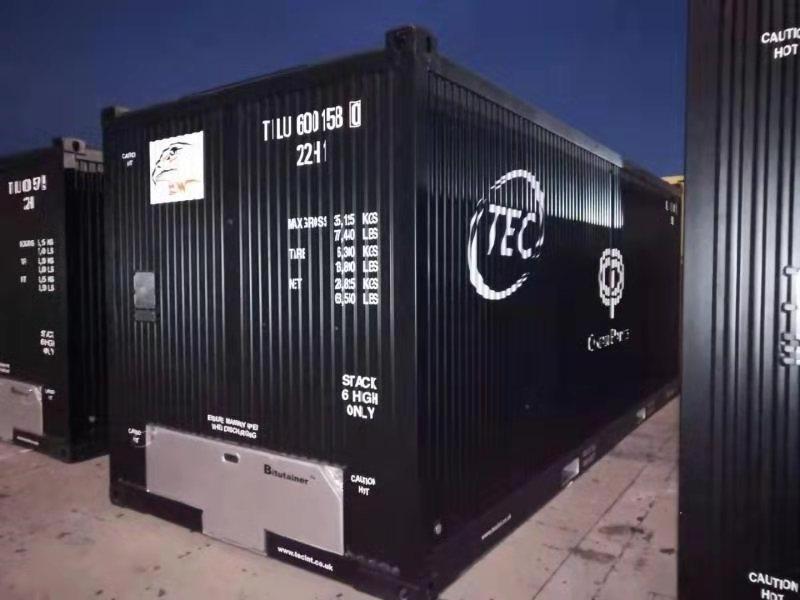

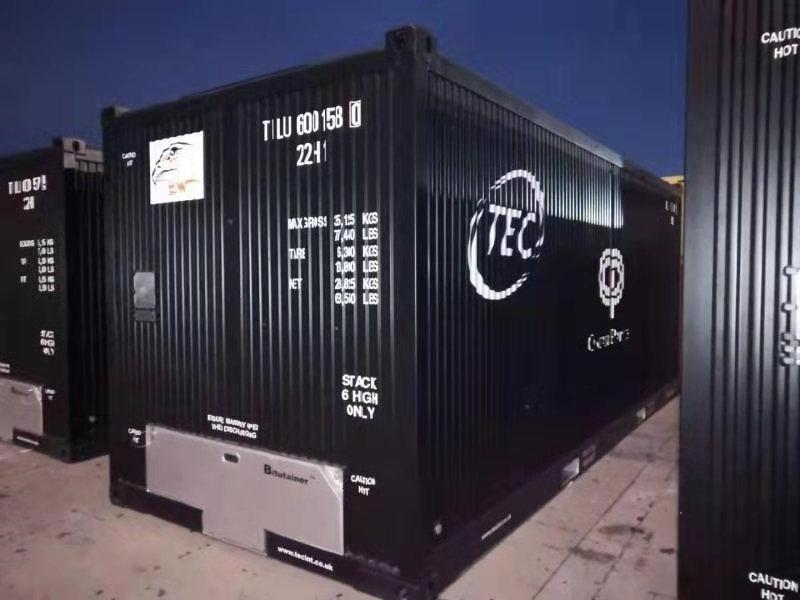

Quick Details

-

Type:

-

Dry Container

-

Capacity:

-

25000L

-

External Dimensions(l x W x H)(mm):

-

1292x2591x2438

-

Internal Dimensions(l x W x H)(mm):

-

12000x2273x2294

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CIMIC

-

Standard:

-

T11 IMDG, US DOT C

-

MAWP:

-

4bar

-

VESSEL DESIGN TEMP.:

-

-40℃ to 130℃.

-

CLASSIFICATION:

-

Bureau Veritas or LR

-

MATERIAL:

-

SA516 Gr 70 Carbon steel .

-

SAFETY RELIEF VALVE:

-

3" flanged 4.4 bar

-

MANLID:

-

1 x stainless steel, 500mm

-

TOP DISCHARGE PROVISION:

-

1 x 3" recessed tank pad

-

AIR INLET:

-

1.5" ball valve

-

Certification:

-

ISO9001

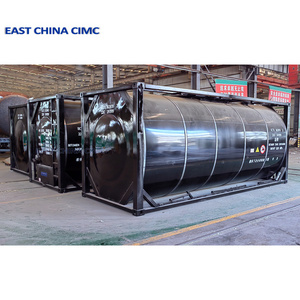

Packaging & Shipping

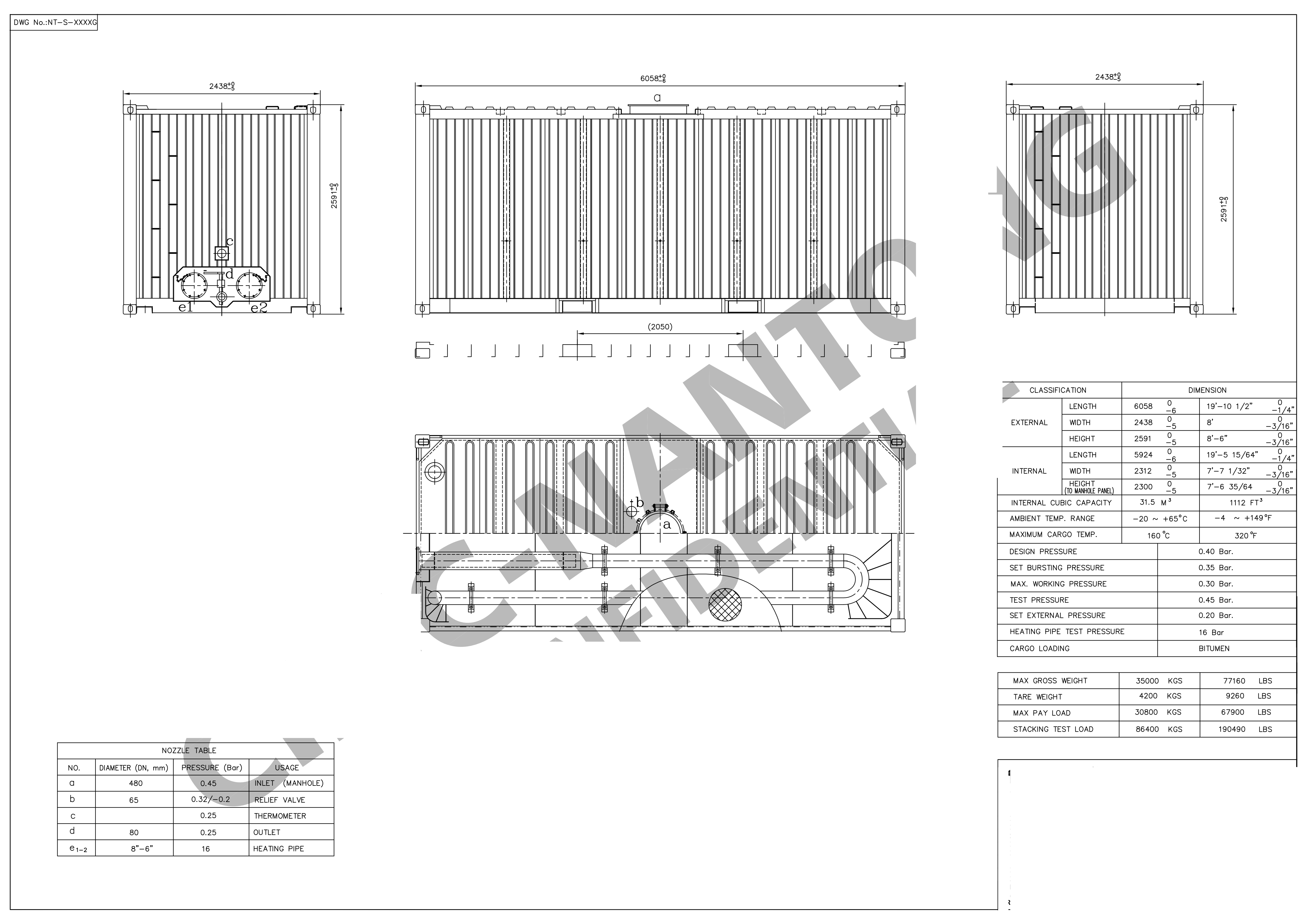

DESIGN SPECIFICATION

TANK TYPE

| 20ft ISO UN universal Collar(set out) tank. |

VOLUME

25,000 litres -1.5,+1.5

%

.

USEABLE

CAPACITY(deducting

internal heating tubes)

24,100 litres -1.5,+1.5

%

.

TARE

6220 kg nominal.

MAX GROSS

36000 kg.

PRODUCTS

Cut back bitumen (UN 1999)

MAWP

1.77 bar.

TEST PRESSURE

2.65 bar.

EXTERNAL PRESSURE

0.21 bar.

VESSEL DESIGN TEMP.

:

-40

℃

to 250

℃

.

TYPE APPROVALS

T3 UN portable tank (US DOT, UK DfT, ADR/RID),

UIC, TIR, CSC, TC.

CLASSIFICATION

Bureau Veritas

2.0VESSEL

DESIGN CODE

ASME

Div 1 where applicable.

MATERIAL

Shell Material: SA 516 GR70.

Corrosion allowance 0 mm.

Ends Material: SA 516 GR70.

Corrosion allowance 0 mm.

SURFACE POLISH

Base 400 mm of circumferential seams ground flush.

Fillet welds on tank fitting ground smooth where

3.0FRAME

TYPE

ISO 1496/3 (1CC) without saddles.

MATERIAL

SPA-H or equivalent.

WALKWAY

475mm wide non-slip aluminium. Two longitudinal full

length walkway beside the manway box. One transverse

walkway at the front end frame. Full transverse

walkways between the rear end frame and manway box.

500mm dia. hinged 8 point manlid.

Made of carbon steel.

Graphite composite gasket

Fitted in manlid assembly.

4” stainless steel gate valve with 4” BSPT dust cap.

4.5)

HEATING

SYSTEM

2 set fire tube for burner.

The tank inside shall be fitted with two pairs of carbon

s

teel heating pipes and exhaust at the top. Diameter of

heating pipes is 219mm, one short stainless steel pipe

set in the carbon pipe at flame area.

Heating using diesel burners. ( supplied by customer )

4.6)

SPILLAGE

AREAS

One spillage tray around manlid, relief valve and

rupture disc.

The tray should be insulated.

4.7)

DOCUMENT

HOLDER

Φ

75×325mm plastic document holder fitted to rear end

frame.

4.8)

THERMOMETER

Glycerin filled analogue thermometer, range from -40

℃

to +300

℃

5.0INSULATION & CLADDING

5.1) Insulation

Barrel & ends

75mm thickness rockwool where possible.

Under the banding

:

Compress rockwool under the stainless steel banding.

5.2) Cladding

Barrel and Ends: 0.8mm thick color carbon steel sheets.

Color: RAL2011.

6.0EXTERNAL CORROSION PROTECTION

SHOTBLAST

SA 2

1

/

2

to framework.

CARBON STEEL

FRAMEWORK

Primer coat: DWep ZINC 300, 30 microns DFT.

Intermediate coat: DWep AC 80, 50 microns DFT.

Top coat:

DWpu FINISH 20

ORANGE, 40 microns DFT.

Total: 120 microns DFT.

Our Services

The containers specified herein are manufactured under sufficient quality control, which will be approved by one of following authorized agency.

ASME, IMDG, ADR, CSC, ISO

Hot Searches