- Product Details

- {{item.text}}

Quick Details

-

Material:

-

S50C, P20 or customized

-

Mould life:

-

300000-1000000shots

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Surface treatment:

-

Polishing

-

Size:

-

Customized Size

-

Drawing Format:

-

PDF/CAD/3D/STP/AI

Quick Details

-

Shaping Mode:

-

Silicone Mould

-

Place of Origin:

-

Guangdong, China

-

Product Name:

-

silicone rubber mold

-

Material:

-

S50C, P20 or customized

-

Mould life:

-

300000-1000000shots

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Surface treatment:

-

Polishing

-

Size:

-

Customized Size

-

Drawing Format:

-

PDF/CAD/3D/STP/AI

Product Description

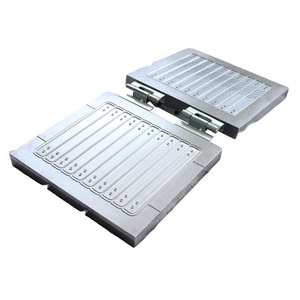

Factory Customized Precision Silicone Rubber Mould Tooling Mold/Rubber Mould/Silicone Mold Tool for silicone rubber products

1. Technicial data for mould

| 1 | Cavity material | 45#,50#,2738,2343,DIN-1,S130,H13,2344,738H,718,8407,S136,NAK80,P20,KD-61,NIMAX ect |

| 2 | Steel hardness | 20-60HRC |

| 3 | Treatment | Pre-Harden, Nitriding, Heat treatment, Quenching |

| 4 | Cavity Qty | Single-cavity / Multi-cavity |

| 5 | Mould Life | 500K - 5millon shots at least |

| 6 | Design Software | UG, CAD, 3D MAX ,PRO-E, Solid Works etc, |

| 7 | Process | CNC, high speed carve, EDM, wiring-cutting, drill, polish etc |

| 8 | Quality | ISO9001:2000 Certificate |

| 9 | Lead Time | 10-30 workdays depends on the different products |

| 10 | Package | Wooden Case Package or according to customer requirement |

1). Product Design

Customer send us the product drawing directly or we draw the product according to the sample,then we send customer the product drawing to confirm

2). Mould Design

We'll start to design mould after the product drawing confirmed,then send customer the mould drawing to confirm

3). Mould Making

The mould start to make after the mould drawing confirmed,the process include prepare steel,rough cut,finish machining,assembly etc

4). Mould Test

We'll test the mould after mould assembly,then we'll send customer samples and video of mould test to confirm

5). Final Process

The mould start to polish if the sample is ok,and make grain,nitridation or chroming if customer required

6). Mould Test

We'll test the mould again after polishing,then send customer the final sample and video of mould test to confirm

Packaging & Shipping

Our Services

Hot Searches