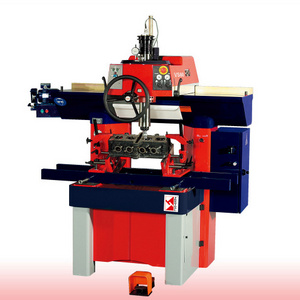

2. Light boring head of patent-based design is equipped with triple air flotation device, self-centering system and combined motor shaft.

3. Designed specially for repairing small-sized engine and compound-cylinder engine used on motorcycle and automobile.Meet the requirements of high precision machining for valve guides with a small diameter of 3mm.

4. With distinctive characteristics of this new type machines that can save 30% cutting force during machining process. Ensure the angle accuracy of compound angle tool within a range of ±0.5 .

5.Machining capacity: 16mm/0.63" - 50mm/1.97" .

6.Modernized design of standard machine body to agree with the improved rigidity. Dynamic and static features are optimized by computer to provide the most advanced machining process.

7. Improved lighting system.

8.Pneumatic clamping of table bars.

4. With distinctive characteristics of this new type machines that can save 30% cutting force during machining process. Ensure the angle accuracy of compound angle tool within a range of ±0.5 .

5.Machining capacity: 16mm/0.63" - 50mm/1.97" .

6.Modernized design of standard machine body to agree with the improved rigidity. Dynamic and static features are optimized by computer to provide the most advanced machining process.

7. Improved lighting system.

8.Pneumatic clamping of table bars.

9.Fully integrated spindle motor: Infinitely variable spindle speed, 100 to 1200 RPM, with sensorless Vector Flux Control in open loop (extremely broad torque ratings from lowest RPM.).

10. Lightweight workhead: built-in spindle motor and triple air-float automatic centering system.Minimal workhead inertia and maximal floatation for unmatched centering sensitivity.

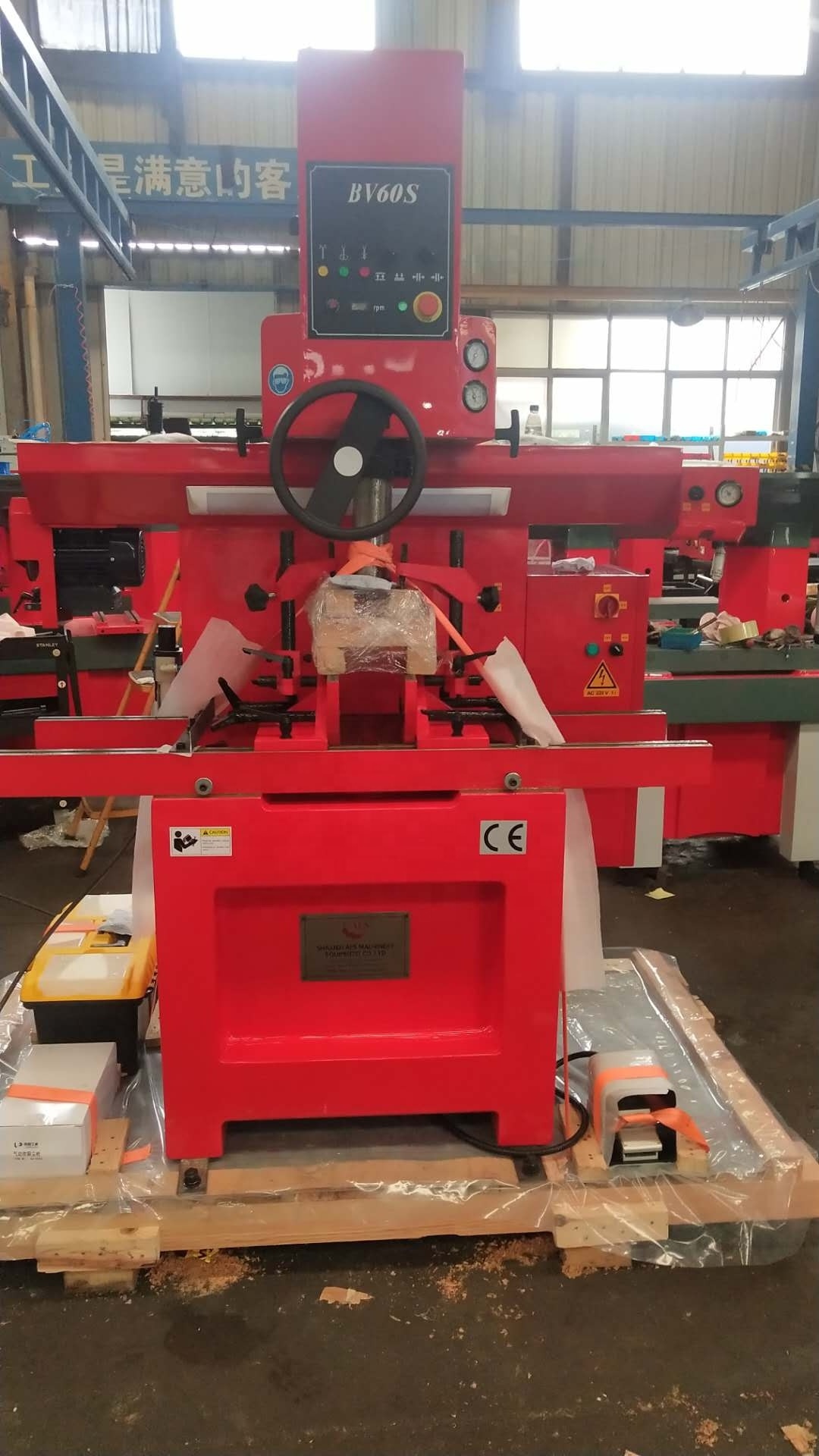

11.High-quality three color saturation painting.

10. Lightweight workhead: built-in spindle motor and triple air-float automatic centering system.Minimal workhead inertia and maximal floatation for unmatched centering sensitivity.

11.High-quality three color saturation painting.