- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Mingxin

-

Voltage:

-

380V

-

Weight:

-

800 KG

-

Dimension(L*W*H):

-

2000*1400*1000 mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

briquette charcoal coal and charcoal extruder machine

-

Raw material:

-

charcoal powder

-

Usage:

-

BBQ,Shisha,heater,wood processing

-

Capacity:

-

as the need of customers

-

Function:

-

making charcoal

-

Color:

-

Green red blue yellow orange

-

Mold:

-

Cube, round(variable)

-

Heating Method:

-

Electricity

-

Feature:

-

Efficiency

Quick Details

-

Warranty:

-

1 Year

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingxin

-

Voltage:

-

380V

-

Weight:

-

800 KG

-

Dimension(L*W*H):

-

2000*1400*1000 mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

briquette charcoal coal and charcoal extruder machine

-

Raw material:

-

charcoal powder

-

Usage:

-

BBQ,Shisha,heater,wood processing

-

Capacity:

-

as the need of customers

-

Function:

-

making charcoal

-

Color:

-

Green red blue yellow orange

-

Mold:

-

Cube, round(variable)

-

Heating Method:

-

Electricity

-

Feature:

-

Efficiency

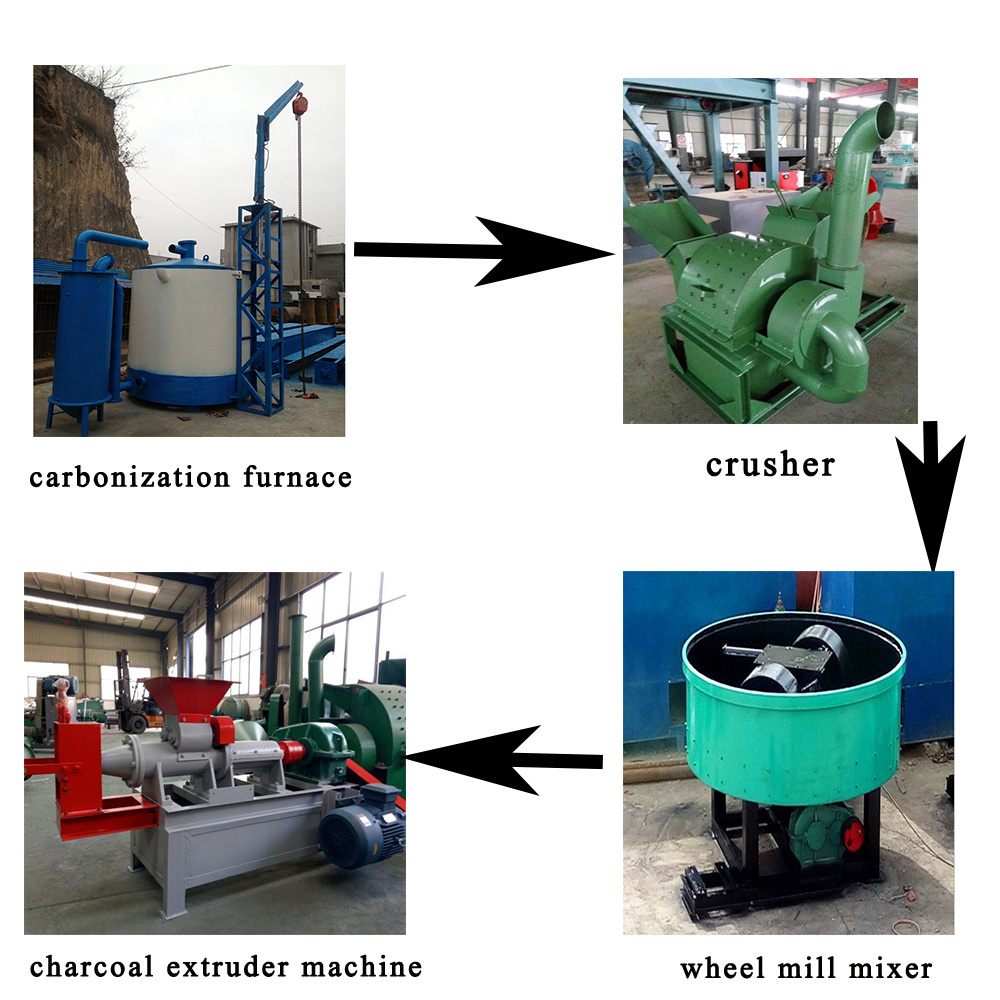

Introduction

Feature:

|

Model

|

Power (kw)

|

Capacity (kg/h)

|

Dimension (mm)

|

Weight (kg)

|

|

140

|

11

|

800-1000

|

2000*1400*1000

|

650

|

|

180

|

18.5

|

2000-3000

|

2200*900*1200

|

800

|

Package

Henan Mingxin Machinery Co., Ltd is a modern enterprise that integrates design, research and development, production, sales, and export, specializing in the production of clean energy equipment, energy-saving equipment, and waste recycling equipment. All products adopt international quality standards. Our company adheres to the corporate spirit of people-oriented, honest and trustworthy, technological innovation, and pioneering spirit. We always take technology as the driving force and market orientation to make our products first-class. In order to ensure customer satisfaction, our company uses service skills as a carrier to provide customized solutions for customers, continuously optimizing equipment and facilities, and relying on the most professional knowledge and comprehensive technical support, we strive to implement comprehensive quality testing measures in all aspects of production.