- Product Details

- {{item.text}}

Quick Details

-

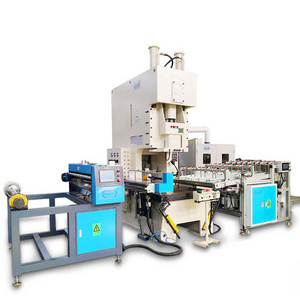

Model Number:

-

GS-110

-

Quality:

-

500 million times punching at least

-

Nominal Pressure:

-

1100KN

-

Slide Block Strok:

-

150-260mm

-

Slide Stroke Per Minutes:

-

50-40

-

Maximum Die Set Height:

-

345-500mm

-

Die Set Height Adjustment:

-

90mm

-

Slide Bottom Size:

-

630*520mm

-

Stemhole Size:

-

60*85mm

-

Bolster Surface Size:

-

1100*680/1300*800mm

-

Total Power:

-

11-15KW

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Goldshine

-

Model Number:

-

GS-110

-

Quality:

-

500 million times punching at least

-

Nominal Pressure:

-

1100KN

-

Slide Block Strok:

-

150-260mm

-

Slide Stroke Per Minutes:

-

50-40

-

Maximum Die Set Height:

-

345-500mm

-

Die Set Height Adjustment:

-

90mm

-

Slide Bottom Size:

-

630*520mm

-

Stemhole Size:

-

60*85mm

-

Bolster Surface Size:

-

1100*680/1300*800mm

-

Total Power:

-

11-15KW

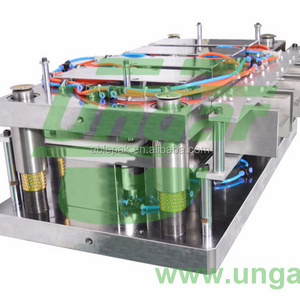

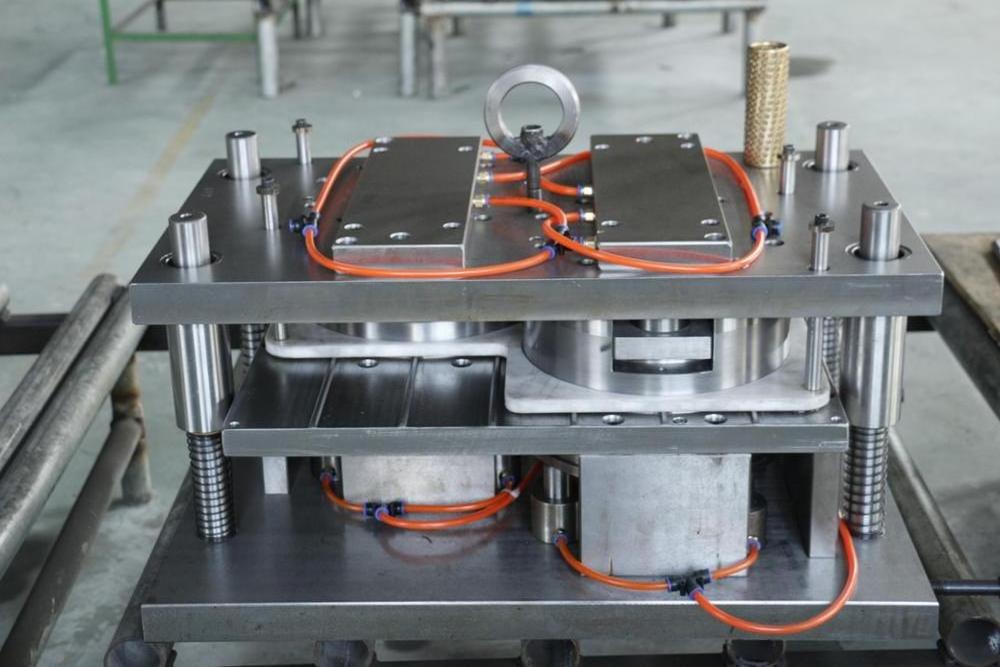

Features of aluminium foil container tray making machine

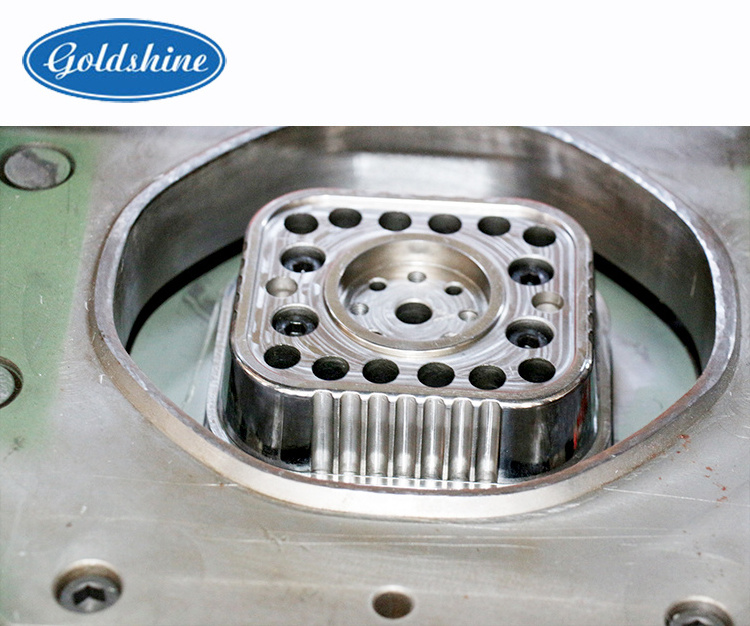

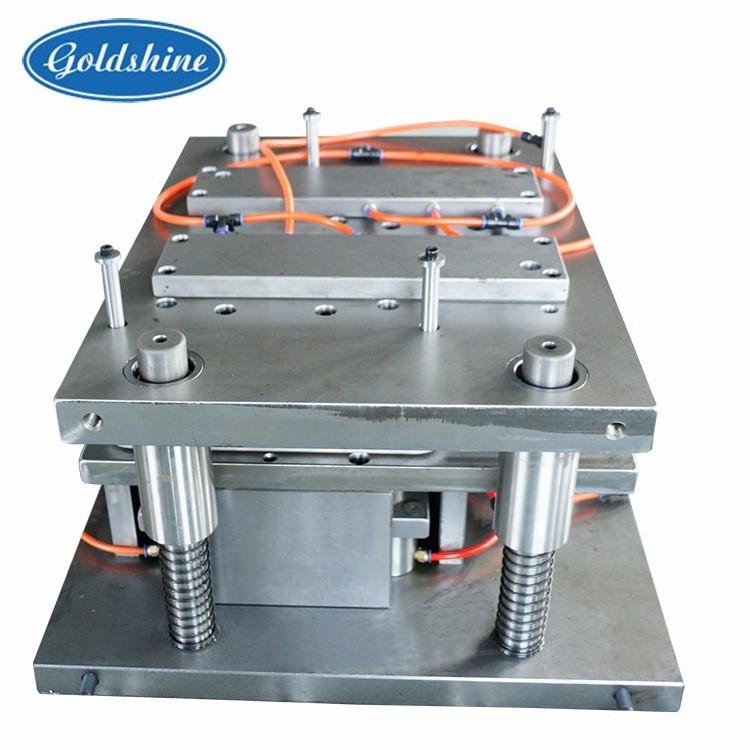

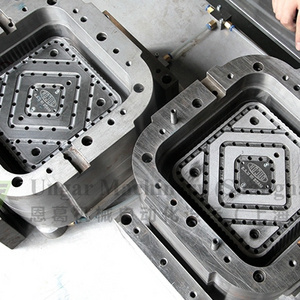

The development and production of aluminum foil stamping mold is one of our company's supporting projects. We introduce the machining centers (vertical), CNC milling machines (duplicating), CNC electric discharge machines, NC high-speed, low-speed wire cut electrical discharge machining and other advanced processing machine of mold from USA, Japan, Western European and ETC. And we also adopt the advanced assistant designing system (PRE/CAN/CAE/CAM) in the mold designing. We can produce or processing all kinds of aluminum foil stamping mold according to user's requirement.

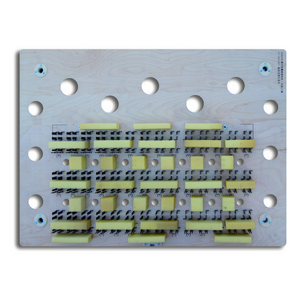

The mold components of

aluminium foil container tray making machine

|

Material Name of Mold

|

Steel Alloy

|

Origin

|

||

|

High Chrome Steel

|

DC53

|

Japan

|

||

|

High Chrome Steel

|

SKD11

|

Japan

|

||

|

9CrWMn

|

K460

|

Austria

|

||

|

Chrome Steel

|

Cr12mov

|

China

|

||

|

Chrome Steel

|

Cr12

|

China

|

||

|

Steel

|

S50C

|

Japan

|

||

|

Medium Steel

|

45#

|

China

|

||

|

The Mold holder is made of Precise hardware steel plate covered with four column copper base steel ball.

|

|

|

||

|

Guide pare(Order)

|

Guide Pare(Material)

|

Mold Holder Material

|

||

|

Packaging

|

|

|

|

Size

|

According to the mold

|

|

|

Weight

|

200kg

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How long is your delivery time?

A: Generally it is 35-40 days, it is according to your quantity.

Q: Can you do the machines' appearance design for us?

Yes. We have a professional team with rich experience in machine's

appearance

design and manufacturing.

Q: What is your terms of payment ?

A: L/C,D/P,T/T,Western Union.