- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤1g

-

Voltage:

-

220V

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GROUNTON

-

Dimension(L*W*H):

-

46*30*20CM

-

Weight:

-

50 KG

-

Product name:

-

GTX Series Paste Filling Machine

-

Filling speed:

-

1 ~ 80 bottles / minute

-

Filling accuracy:

-

any filling volume ± 1g

-

Single filling volume:

-

2ML ~ 90000ML

-

Air pressure:

-

0.4 ~ 0.9Mpa

-

Drive control form:

-

PLC precise pulse control of servo motor

-

Type:

-

Filling Machine, Filling Machine

-

After-sales Service Provided:

-

Video technical support

Quick Details

-

Machinery Capacity:

-

400BPH, 500BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Paper, Metal, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

≤1g

-

Voltage:

-

220V

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GROUNTON

-

Dimension(L*W*H):

-

46*30*20CM

-

Weight:

-

50 KG

-

Product name:

-

GTX Series Paste Filling Machine

-

Filling speed:

-

1 ~ 80 bottles / minute

-

Filling accuracy:

-

any filling volume ± 1g

-

Single filling volume:

-

2ML ~ 90000ML

-

Air pressure:

-

0.4 ~ 0.9Mpa

-

Drive control form:

-

PLC precise pulse control of servo motor

-

Type:

-

Filling Machine, Filling Machine

-

After-sales Service Provided:

-

Video technical support

Key Features:

Servo-driven positive displacement pumps for unparalleled filling accuracy

High-speed operation and optimized filling cycles for exceptional efficiency

Handles a wide range of product viscosities, from thin liquids to thick pastes

Gentle filling action preserves product integrity

Adaptable to various container sizes and shapes

Benefits:

Reduces product waste and inconsistencies

Increases production output

Lowers operating costs and environmental impact

Enhances product quality and consistency

Expands production capabilities

Applications:

Cosmetics and personal care products

Food and beverages

Pharmaceuticals and chemicals

Industrial lubricants and paints

Elevate Your Filling Operations

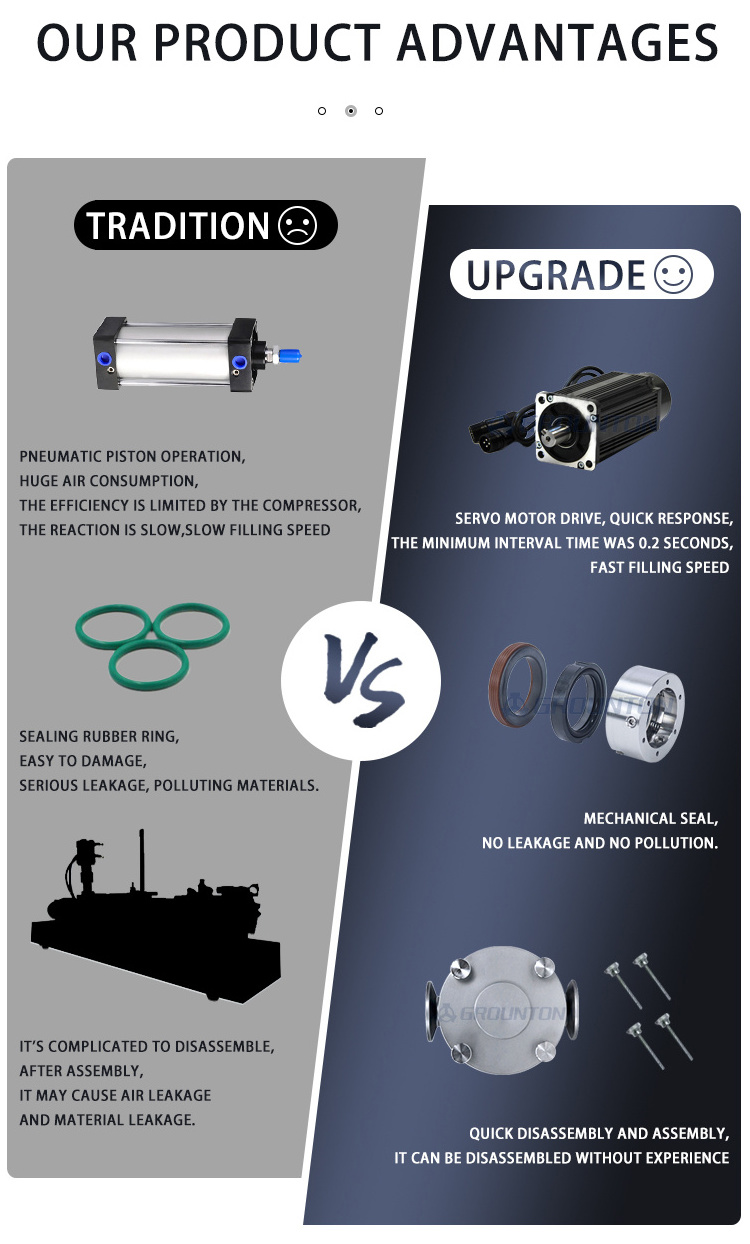

| Comparison of product advantages |

1.PNEUMATIC PISTON OPERATIONHUGE AIR CONSUMPTIONTHE EFFICIENCY IS LIMITED BY THE COMPRESSORTHE REACTION IS SLOW , SLOW FILLING SPEED

|

1. SERVO MOTOR DRIVE , QUICK RESPONSETHE MINIMUM INTERVAL TIME WAS 0.2 SECONDS ,FAST FILLING SPEED

2. MECHANICAL SEALNO LEAKAGE AND NO POLLUTION 3. QUICK DISASSEMBLY AND ASSEMBLY IT CAN BE DISASSEMBLED WITHOUT EXPERIENCE |

|

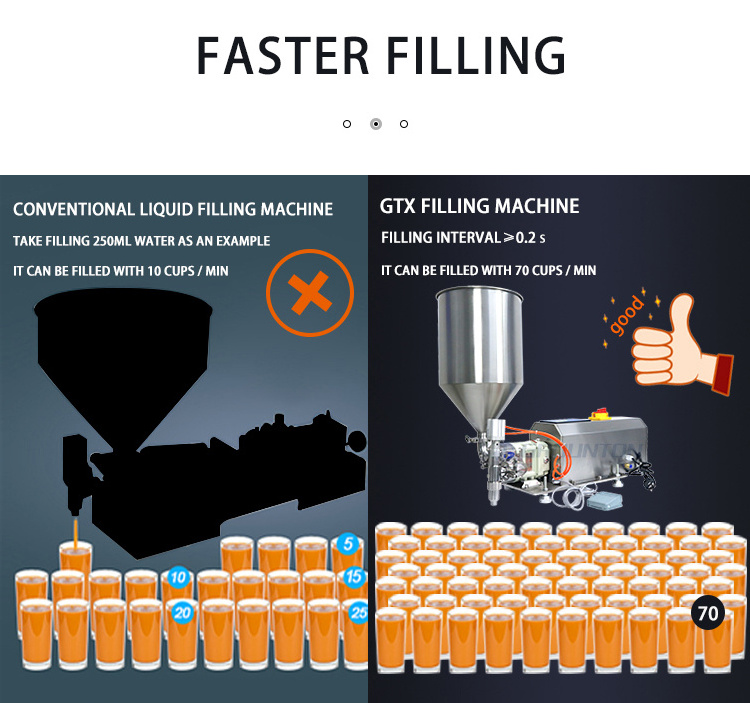

Fast filling speed (70 bottles / min) interval speed ≥ 0.2S,wide filling range (5ml-50000ml).

It is suitable for low viscosity liquid or granular paste in food, medicine, chemistry, biology and other fields.

PRODUCT DESCRIPTION

1.PLC CONTROLLER : MICROCOMPUTER CONTROL, SIMPLE OPERATION,ACCURATE MEASUREMENT.

2.DRIP PROOF FILLING HEAD :IT CAN EFFECTIVELY SOLVE THE PROBLEM OF DRIPPING AND LEAKAGE, WITH FAST DISCHARGING AND NO DRIPPING.

3.ELECTRONIC CONTROL ELEMENT : FOOT START, ROTARY SWITCH,WATER WASHING KNOB, HUMANIZED DESIGN, EASY TO USE.

| Serial number | Product specifications | 1s single filling volume ml | Operating speed r | Equipped with power kw | Diameter φ |

| 1 | RX-900 | 5~50000 | 1~1000 | 0.75 | 32 |

| 2 | RX 2000 | 10~100000 | 1~1000 | 1 | 38 |

| 3 | RX-4000 | 20~200000 | 1~1000 | 1.5 | 50 |

1. What is the delivery period for the machine?

The delivery period for the machine is mainly within 30 days. If you

are in great hurry, please contact us for the details.

2. How about the after service and gurantee period?

We make the gurantee time 12 months from the machine's arrival in

buyer's facility and we have professional team with experienced

technician and do the best after service to assure the machine whole life uage.