- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yugong Machine

-

Voltage:

-

380V,3-phase

-

Power:

-

18kw

-

Dimension(L*W*H):

-

L3250mm*W1700mm*H2000mm

-

Weight:

-

2000 kg

-

Marketing Type:

-

Hot Product 2021

-

Raw material::

-

PE Coated Paper

-

Cup Side Welding::

-

Ultrasonic Heater

-

Finished Products::

-

Paper bowl

-

Suitable Paper Weight::

-

180~350gsm

-

Support customization::

-

bowl mold; packaging method

-

Support bowl type::

-

single layer; double layer

-

Additional Support::

-

Video Technical Instructions

-

Whatsapp:

-

0086 155 1568 2190

Quick Details

-

Production Capacity:

-

60-80 pcs/min

-

Processing Type:

-

paper bowl machine

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Yugong Machine

-

Voltage:

-

380V,3-phase

-

Power:

-

18kw

-

Dimension(L*W*H):

-

L3250mm*W1700mm*H2000mm

-

Weight:

-

2000 kg

-

Marketing Type:

-

Hot Product 2021

-

Raw material::

-

PE Coated Paper

-

Cup Side Welding::

-

Ultrasonic Heater

-

Finished Products::

-

Paper bowl

-

Suitable Paper Weight::

-

180~350gsm

-

Support customization::

-

bowl mold; packaging method

-

Support bowl type::

-

single layer; double layer

-

Additional Support::

-

Video Technical Instructions

-

Whatsapp:

-

0086 155 1568 2190

Product Description

Why don't

contact me?

1. Provide most suitable machine model

2. Provide the most suitable construction plan

3. Get the latest discounts on purchases!

Note: Scan WhatsApp QR code

1. Open WhatsApp and tap Settings.

2. Tap the QR code icon displayed next to your name.

3. Click Scan > OK.

4. Hold the device and scan it at the top of the QR code.

5. Click Add Contact.

6. Open wealth~

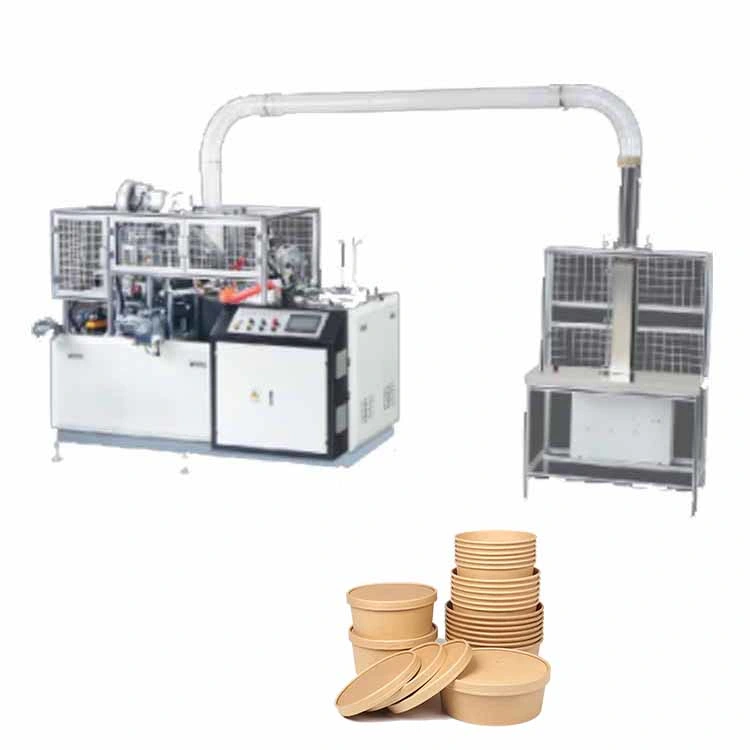

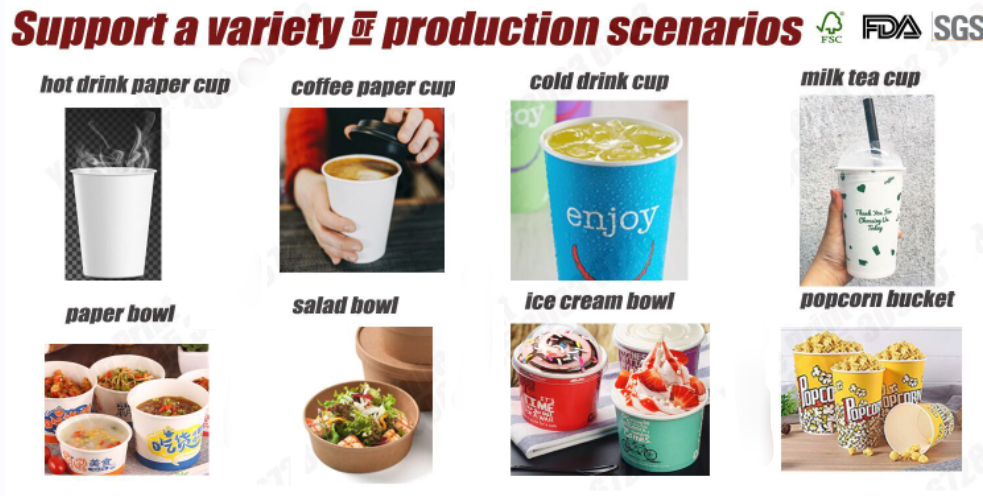

paper Bowl machine

is a machine that have double turntable, dual-segment high-performance with functions of automatic paper fanfeeding, imported heater side seal, cup top lubrication, automatic bottom paper feeding, double curling artwork, automatic cupcollect and stock. Can make cups both single PE and double PE, for cold drinks and hot drinks.This machine speed can reach 60-80 pcs/min.

paper cup forming machine is a fully automatic paper cup forming machine, which can produce different sizes of paper cups with a series of continuous process, including automatic paper feeding through more than 2 times, paper anti-withdrawal device (to ensure accurate positioning), ultrasonic welding, transferring paper fan by magic hand, silicone oil lubricating, bottom punching, bottom folding, bottom pre heating, bottom knurling, cup discharging. The machine, researched and developed by our company, is improved in stability after comprehensive technical improvements.

The whole steps are :

1 . Buy the cutted bottom-using rolling paper and bowl-side-using sheet paper from PE coated paper suppliers ; In this step, the suppliers will cut the paper sizes according to your requirement.

2 . Pre printing and pre cutting, you can let them done out-serve or buy machines to finish them ;

3 . Forming bowls in paper bowl machines ; The same for paper bowl/bucket.

4 . Packing the finished bowls in plastic bags and then to cardboard box.

paper bowl machine is improved based on the normal chain driving type. This machine runs a whole procedure of paper-feeding,bowl fan-wall sealing, oiling, bottom punching, heating, rolling, rimming, rounding and tripping. It is an idea equipment forproducing drinking bowls,market bowls, coffee bowls, advertising bowls , etc. It is widely used for hot drink and beverage. If youneed double pe coated paper bowls or paper gram higher 250g/m2, we recommend you to use Ultrasonic paper bowl machine, it canproduce single pe coated paper bowls and double pe coated paper bowls.

Leading technology:

1. Adopt open CAM and gear transmission system. Machine run stably under high speed operation.

2. Using hot air heating system, to keep cups no leaking under high speed.

3. The parts are all made of standardized production, strong commonality, swap performance is good, easy to maintena -nce.

4. The automatic lubrication system, closed, can ensure the machine long time continuous high-speed operation.

5. Intelligent design, PLC automatic control, automatic fault alarm, count. Testing, and stop action.

6. The machine is a compact paper cup machine helping clients to save 60% shipment cost.

7.Bottom sealing by hot air devices,so that the machine is efficient,the hot air device is imported from Switzerland.

8.And cup side sealing by ultrasonic.

9.More efficient and higher performance.

10.Cup top curling and bottom knurling are finished by separate turn-plates.

11.It is easy to make cups with different sizes by changing moulds.

12.With automatic cup delivery system with counter.

Specification

|

Max Paper Cup Size

|

1000ml

|

|

speed

|

55-80PCS/MIN

|

|

Raw material

|

180~~400gsm Single PE or Double PE coated paper

|

|

Air consumption

|

0.2 cbm/min

|

|

Electricity

|

380V 3 phases or 220V 3 phase

|

|

General power

|

11kw

|

|

Weight

|

3000kgs

|

|

Whatsapp

|

0086 155 1568 2190

|

|

email

|

pacey@yg797.com

|

Final Product

Amazon Paper cup Sales Leaderboard

I collected data on the best-selling paper bowl on Amazon. It includes parameters such as photos/sales/prices for you to choose in

advance. Contact me on whatsapp or email , I will send it to you without reservation.

For amazon paper cup Top 50 products, the sales quantity in the last 30 days is 127958, the sales amount is $2947303, and the

average profit margin reaches 46.6%.

advance. Contact me on whatsapp or email , I will send it to you without reservation.

For amazon paper cup Top 50 products, the sales quantity in the last 30 days is 127958, the sales amount is $2947303, and the

average profit margin reaches 46.6%.

Product Advantage

multiple mediation

The times of paper feeding and multiple mediation to avoid uneven sides of the paper bowl.

groove wheel connection

The machine internal use of groove wheel connection, each part of the connection is more closely, the machine operation process is not easy to loosen, the situation of more accurate work.

PLC Control

The machine is controlled by PLC, which makes it more intelligent and precise.

Complicated bottom suction paper feeding process is easy to turn over the bottom phenomenon

as bowl bottom paper roll is heave,so here is use automatic system life bottom paper roll,

machine equipped with automatic robot hand to collect paper bowls

Our service

Whole process guidance

With more than 15 years of service experience,

we will spare no effort to provide support in selecting equipment, customizing production lines, improving supply chain, and post-optimization etc.

Device debugging support

When the equipment is delivered to your plant,

we will provide support in equipment installation, performance adjustment, and simulation operation until your equipment starts normal production.

Support customization

Relying on our powerful flexible production line, we can give you the right to fully choose the mold, drive method, accessories upgrade, shell material, appearance color and Logo etc.

Extensive spare parts service

The spare parts warehouse of more than 50,000 square meters can meet the timely replacement and

supplement of any wearing parts.

Support sea, land and air transportation

We can ship products to every corner of the world. If you need, we also support a series of tedious tasks such as customs clearance and tail end delivery.

Packing & Delivery

solid packaging

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

comprehensive service

We also support air/sea/railway/automobile/bulk carrier, etc.;

Support from anywhere in China to anywhere in the world;

We can also help you to handle shipping/customs clearance/pay duties/delivery to your company and other services.

Hot Searches