- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/50HZ

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

KEFAI

-

Dimension(L*W*H):

-

1300*800*800mm

-

Weight:

-

130 KG

-

Name:

-

KEFAI desktop bottle labeling machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Use:

-

be used for labeling different bottles and cans

-

Labeling speed:

-

45 m/min

-

Labeling accuracy:

-

±1mm

-

Material:

-

S304 Stainless Steel

-

Operate:

-

manual book and demo video

-

Bottle type:

-

bottles,cans

Quick Details

-

Application:

-

Food, Beverage, Commodity, Chemical, Machinery & Hardware

-

Packaging Type:

-

Bottles

-

Packaging Material:

-

Wood

-

Voltage:

-

220V/50HZ

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

KEFAI

-

Dimension(L*W*H):

-

1300*800*800mm

-

Weight:

-

130 KG

-

Name:

-

KEFAI desktop bottle labeling machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Use:

-

be used for labeling different bottles and cans

-

Labeling speed:

-

45 m/min

-

Labeling accuracy:

-

±1mm

-

Material:

-

S304 Stainless Steel

-

Operate:

-

manual book and demo video

-

Bottle type:

-

bottles,cans

Product Description

Product Introduction

1. advanced and friendly human-machine interface system, simple and intuitive

operation, full-featured, with rich online help function

2.The machine structure is simple, compact, easy to operate and maintain

3. Adoption of well-known brand motor drive,stable and reliable delivery speed

Working Principle

* Core principle: the sensor detects the product passing return signal to the control labeling system, PLC signal after processing, at the appropriate time delivering the label attached to the product in the set position, the product flows through the cover label, labels, coated solid , a label attached to the action is completed.

* Procedure: put the product (which can be accessed pipeline) -> product delivery (automatically) -> Products correct (automatically) -> Product Inspection (automatically) -> labeling (automatically) -> Cover standard (automatically ) -> label products have been collected.

Features

1.The whole machine adopts a mature PLC control system to make the whole machine run stably and at high speed.

2. General-purpose bottle separation device, no need for replacement of parts for any diameter bottle shape,quick adjustment and positioning Note:(optional and adjustable rotating wheel included) to achieve the perfect universal bottle labeling machine.

3.Operating system with touch screen control, easy operation, practical and highefficiency .Adopting labeling speed, conveying speed and dividing speed can realizestepless speed regulation and adjust according to need.

Application

Specification

Remark: Price on the page is standard model.

If you need the Date Priting,or

Transparent label,Fixed positioning labeling,will be extra cost.Pls consult with our sales.We also can customize according your bottle size.

|

item

|

Round Bottle Labeling Machine

|

|

Model

|

KF06-AL-D

|

|

Voltage

|

AC220V 50Hz

AC110V 60Hz |

|

Power

|

400w

|

|

Labeling speed

|

25-50 pcs/min

(related to material and label size) |

|

Labeling accuracy

|

± 1.0mm

(material and label size excluded) |

|

Label roll inner diameter

|

≥φ75mm

|

|

Max label roll out diameter

|

≤φ250mm

|

|

Suitable bottle

|

Φ40mm-100mm

|

|

Biggest label size

|

W*L 150*180mm

|

|

Packing size

|

130*80*80cm

|

|

Packing weight

|

130kg

|

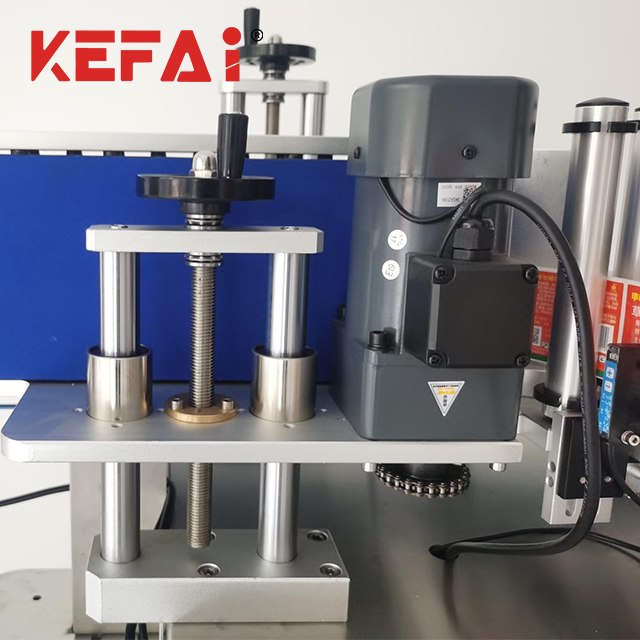

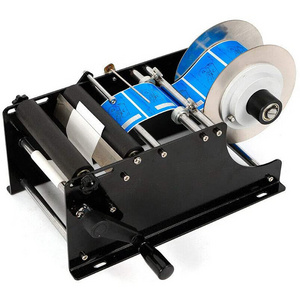

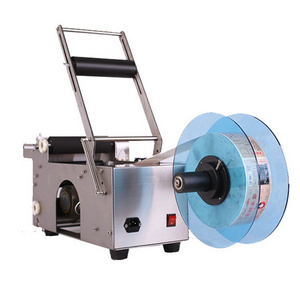

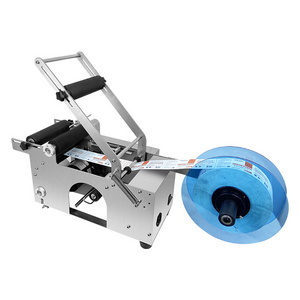

Deatils images

For More Details,

Please Send An Inquiry To Get It.

Packing & Delivery

All the products before delivery should be tested by assemble and debugging engineer, wiped up and cleaned, the wrapped by stretch film to protect it from moist. The precision part needs flexible package. In addition, without standard tools, manual and other documents, and allow ex-factory confirmation sheet, the machine cannot leave factory. All the products will be packed in wooden case. The exported products use plywood case to pack. The foot margin of equipment fixed tightly to make the machine can experience loading and uploading, the upward mark will be posted on the wooden case.

Hot Searches