- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1450*1350*1500mm

-

Weight:

-

1200 KG

-

Product name:

-

Mobile Jaw Crusher

-

Imput size(mm):

-

200-1020mm

-

Max feeding size:

-

200-1020mm

-

The Machines classification:

-

Building Stone Production Line

-

Feed Opening:

-

250x1000mm

-

Customized Service:

-

Support

Quick Details

-

Application:

-

Gold Mining, Crushing stone,ore,coal,sand

-

Place of Origin:

-

Henan, China (Mainland)

-

Brand Name:

-

QIC

-

Dimension(L*W*H):

-

1450*1350*1500mm

-

Weight:

-

1200 KG

-

Product name:

-

Mobile Jaw Crusher

-

Imput size(mm):

-

200-1020mm

-

Max feeding size:

-

200-1020mm

-

The Machines classification:

-

Building Stone Production Line

-

Feed Opening:

-

250x1000mm

-

Customized Service:

-

Support

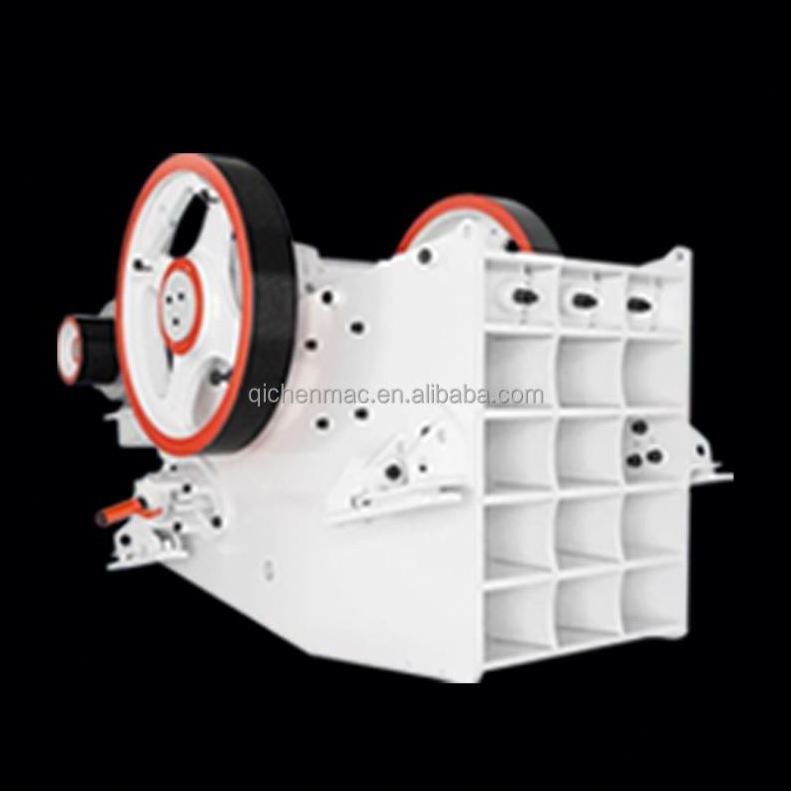

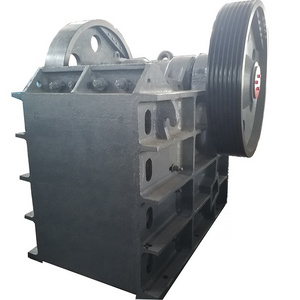

Products Description

pex 250x1000 jaw crushers automatic mini diesel engine rock small size jaw crusher machine for sale

Mobile jaw crusher is widely used for crushing various large stones, limestone, granite, basalt, river pebbles, etc. The maximum compressive strength of materials crushed by jaw crushers is 320MPa. Jaw crushers are mainly used for crushing hard and medium hard stones in stone mining, metallurgical industry, building materials, roads, railways, chemical industry and other industries.

PE series mobile jaw crusher, metal and mining rock crusher price adopts the grid angle design theory and completes the optimum design of the cavity.

Jaw crushers are often used as primary and secondary crushers in mining, metallurgy, construction and other industries. It takes large pieces of rock, ore, concrete, or other material and crushes them into smaller sizes for further processing in a ball mill or hammer crusher.

Related Suggestion

Working Principle

1. The motor drives the belt and the pulley, and moves the movable jaw up and down through the eccentric shaft. When the moving jaw rises, the angle between the bracket and the moving jaw becomes larger, thereby pushing the movable jaw closer to the fixed jaw.

2. At the same time, the material is crushed or chopped to achieve the purpose of crushing;

3. When the moving jaw is down, the angle between the bracket and the moving jaw becomes smaller. The moving jaw is separated from the fixed jaw by the action of the tension rod and the spring. At this time, the broken material is discharged from the lower opening of the crushing chamber.

4. As the motor rotates continuously, the crushing and maneuvering cycle motion crushes and excretes the material to achieve mass production.

2. At the same time, the material is crushed or chopped to achieve the purpose of crushing;

3. When the moving jaw is down, the angle between the bracket and the moving jaw becomes smaller. The moving jaw is separated from the fixed jaw by the action of the tension rod and the spring. At this time, the broken material is discharged from the lower opening of the crushing chamber.

4. As the motor rotates continuously, the crushing and maneuvering cycle motion crushes and excretes the material to achieve mass production.

Product Paramenters

|

Model

|

Max feeding size

(mm) |

Capacity

(t/h) |

Output size

(mm) |

Power

(kw) |

Weight

(kg) |

|

PE150×250

|

125

|

1-3

|

10-40

|

5.5

|

1160

|

|

PE200×300

|

180

|

2-6

|

15-50

|

7.5

|

1240

|

|

PE200×350

|

180

|

3-10

|

18-60

|

11

|

1520

|

|

PE250×400

|

210

|

5-20

|

20-80

|

15

|

2572

|

|

PE400×600

|

340

|

14-36

|

40-100

|

37

|

5800

|

|

PE500×750

|

425

|

30-80

|

50-120

|

45

|

9000

|

|

PE600×900

|

500

|

56-192

|

75-200

|

75

|

18900

|

|

PE750×1600

|

630

|

110-320

|

80-235

|

110

|

29300

|

|

PE900×1200

|

750

|

180-350

|

100-250

|

110

|

55000

|

|

PE1200×1500

|

1020

|

400-800

|

150-350

|

160

|

101000

|

|

PEX150×750

|

120

|

8-35

|

10-40

|

15

|

3350

|

|

PEX250×750

|

210

|

15-45

|

15-50

|

30

|

5000

|

|

PEX250×1000

|

210

|

15-50

|

20-50

|

30

|

6800

|

|

PEX250×1200

|

210

|

20-70

|

20-60

|

45

|

9000

|

Details Images

Features

1. Easy to move.

You can go straight to the broken place. It can run on rough roads as well as flat roads.

2. Compact structure and easy operation.

An integrated equipment group with trailer saves working space. A generator, electric motor and control box are mounted on the trailer to facilitate outdoor work. Equipped with supporting facilities, installation is quick and convenient.

3. Cost savings.

Reduce transportation costs by crushing materials on site.

4. Wide scope of application.

The crushing station can operate independently and can also be combined with other units to form a primary crushing-secondary crushing system or a primary crushing-fine crushing system. In addition, it is also possible to set up a production line for sorting equipment (crushing after sorting, sorting after crushing) according to the customer's request.

5. Stable performance and easy maintenance.

The mobile crushing station is equipped with crushers and vibrating feeders with high quality and reliable performance. Materials are conveyed by a belt conveyor that is easy to operate and maintain. This machine has low investment and high production efficiency.

6. Flexible configuration.

It is possible to customize the work site, material, particle shape, etc. according to the customer's request. Examples of custom machines include single units, combined units, units with automatic unloading belt his conveyors.

Hot Searches