- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

22x30x6

-

Material:

-

Polyurethane

-

Type:

-

UN UNS UHS

-

Color:

-

Blue

-

MOQ:

-

50pcs

-

Package:

-

industrial package

Quick Details

-

Size:

-

22x30x6

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LLH or as youre request

-

Model Number:

-

22x30x6

-

Material:

-

Polyurethane

-

Type:

-

UN UNS UHS

-

Color:

-

Blue

-

MOQ:

-

50pcs

-

Package:

-

industrial package

Product Description

Product Description

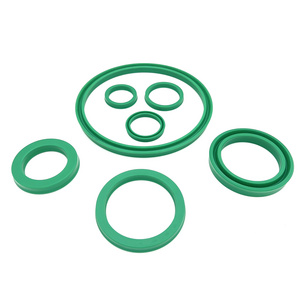

The UNS/UN Piston Rod Seal has a wide cross-section and is an asymmetrical u-shaped sealing ring with the same height of the inner and outer lips. It is easy to fit into a monolithic structure. Due to the wide cross-section, UNS Piston Rod Seal is generally used in a hydraulic cylinder with low pressure.Having been used very widely in hydraulic cylinders, UNS can be used for piston and rod applications because of having the height of both sealing lips equal.

Polyurethane (PU) is a special material that offers the resilience of rubber combined with the toughness and durableness. It allows people to substitute rubber, plastic and metal with PU. Polyurethane can reduce factory maintenance and OEM product cost. Polyurethane has better abrasion and tear resistance than rubbers, and offering higher load bearing capacity.

Compared PU with plastic, polyurethane not only offers excellent impact resistance, but also offers excellent wear resistant and high tensile strength. Polyurethane have subsituted metals in sleeve bearings, wear plates, conveyor rollers, rollers and various other parts, with benefits such as weight reduction, noise abatement and wear improvements

Polyurethane oil seals are mainly used for hydraulic cylinders, easy to install and scrape the dust attached to the piston rod. Polyurethane oil seal has good physical and mechanical properties, wear resistance and oil resistance. It is suitable for the worst working environment, prevents foreign impurities from entering, and achieves excellent sealing performance. They are the most commonly used seals in medium and high pressure hydraulic cylinders.

Detailed Images

|

Material

|

PU

|

|

Temperature(℃)

|

-35~+100°C

|

|

|

Pressure

|

40MPA

|

|

|

Medium

|

Mineral oil based, hydraulic fluids,water

|

|

|

Hardness

|

30-90 shore A

|

|

|

Standard or Nonstandard

|

standard/Customize

|

|

|

Application

|

Heavy machinery, Pump, oil cylinder, etc

|

Other Size:

Other Size:

| 14*22*6 | 25*45*10 | 42*55*10 | UN65*80*11 | UN110*125*12 |

| 14*22*8 | 26*36*8 | 42*62*12 | UN65*80*12 | UN110*125*15 |

| 14*24*5 | 27*35*5 | 45*53*6 | UN65*85*10 | UN110*125*16 |

| 14*24*8 | 28*35*5 | 45*53*8 | UN65*85*12 | UN110*130*9 |

| 14*25*8 | 28*35.5*5 | 45*53*10 | UN65*90*10 | UN110*130*12 |

| 14*26*5 | 28*36*5 | 45*55*6 | UN65*90*12 | UN110*130*15 |

| 15*22*5 | 28*36*6 | 45*55*7 | UN67*77*6 | UN110*130*16 |

| 15*22*6 | 28*36*7 | 45*55*8 | UN67*87*12 | UN112*125*9 |

| 15*22*8 | 28*36*8 | 45*55*10 | UN70*80*5 | UN112*132*15 |

| 15*25*5 | 28*38*6 | 45*56*7 | UN70*80*6 | UN112*132*16 |

| 15*25*6 | 28*38*7 | 45*58*10 | UN70*80*8 | UN115*125*12 |

| 15*25*7 | 28*38*8 | 45*60*9 | UN70*80*10 | UN115*130*9 |

| 15*25*8 | 28*38*10 | 45*60*10 | UN70*80*12 | UN115*130*10 |

| 15*30*6 | 28*40*8 | 45*60*12 | UN70*82*10 | UN115*130*12 |

| 15*30*8 | 28*40*10 | 45*63*8 | UN70*82*12 | UN115*130*15 |

| 15*30*10 | 28*43*10 | 45*63*10 | UN70*85*8 | UN115*135*12 |

| 16*22*5 | 30*37*6 | 45*63*12 | UN70*85*9 | UN115*135*15 |

| 16*22*6 | 30*38*6 | 45*65*10 | UN70*85*10 | UN118*138*15 |

| 16*22*7 | 30*38*7 | 45*65*12 | UN70*85*12 | UN118*138*16 |

| 16*22*8 | 30*38*8 | 45*70*12 | UN70*90*10 | UN120*130*8 |

| 16*24*5 | 30*40*6 | 48*58*6 | UN70*90*12 | UN120*130*12 |

| 16*24*6 | 30*40*7 | 48*58*8 | UN70*95*12 | UN120*135*9 |

| 16*24*8 | 30*40*8 | 48*58*10 | UN71*80*6 | UN120*135*12 |

| 16*26*5 | 30*40*10 | 48*63*10 | UN71*91*12 | UN120*140*10 |

| 16*26*6 | 30*42*7 | 50*58*6 | UN75*85*6 | UN120*140*12 |

| 16*26*7 | 30*42*8 | 50*58*10 | UN75*85*10 | UN120*140*15 |

| 16*26*8 | 30*42*10 | 50*60*6 | UN75*85*12 | UN120*140*16 |

| 16*28*6 | 30*43*10 | 50*60*7 | UN75*90*9 | UN125*140*9 |

| 16*28*8 | 30*45*7 | 50*60*8 | UN75*90*10 | UN125*140*11 |

| 18*24*5 | 30*45*8 | 50*60*10 | UN75*90*12 | UN125*140*12 |

| 18*24*6 | 30*45*10 | 50*60*12 | UN75*95*8 | UN125*145*12 |

| 18*24*8 | 30*47*10 | 50*62*10 | UN75*95*10 | UN125*145*15 |

| 18*25*5 | 30*48*10 | 50*62*12 | UN75*95*12 | UN125*145*16 |

| 18*26*5 | 30*50*8 | 50*63*6 | UN80*90*6 | UN125*150*15 |

| 30*50*10 | 50*63*8 | UN80*90*8 | UN130*145*9 |

Our Service

1. We will respond to your inquiry shortly.

2. Professional staff will help you solve product problems.

3. We can design mold opening according to customer needs.

4. We mainly produce polyurethane and rubber products.

5.100% quality control, 100% full inspection before packaging to ensure zero defect.

6. We can provide you with OEM services with your own trademark.

7. Good after-sales service, please contact me if you have any questions.

8. Looking forward to your inquiry.

Our Company

Jinan Maolei Bearing Co., Ltd is a manufacturer and trader specialized in the research, development and production of bearings. is located in the "Spring City" Jinan, with convenient transportation.

The core products of Jinan Maolei bearing Co,.Ltd have a variety of bearings ranging from deep groove ball bearings, self-aligning ball bearings, self-aligning roller bearings, wheel hub bearings, linear bearings, pillow block bearing, ceramic bearings, plastic bearings, cylindrical roller bearings, angular contact ball bearings, tapered roller bearings, thrust ball bearings, thrust roller bearings and needle roller bearings to spherical plain bearings and other products. All of our products comply with international quality standards ISO 9001 and are greatly appreciated in a variety of different markets throughout the world.

We insist on the philosophies of "integrity" and "pragmatic & win-win business". We also adhere to the "people-oriented" and "advancing" enterprise spirit . "Quality first and customers utmost" is honored as our enterprise concept.

FAQ

Q: Are you trading company or manufacturer ?

We are the manufacture of bearings for more than 20 years, "Quality is our culture".

Q: How long is your delivery time?

A: Generally it is 1-3 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What causes bearing noise?

A: Bearing noise is a function of both the bearing and the way it is used. Some external factors that affect bearing noise include lubricant type, excessive bearing load, and improper installation. Once the abnormal noise occurred, you can contact our engineers, we will help you find the reasons and provide the appropriate solutions.

Q: What is your terms of payment ?

A.100%T/T

B.30%T/T in advance,70% aganist copy of B/L(For large order)

C.Western Union

D.Paypal