- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HICKEY

-

Power:

-

55kw

-

Weight:

-

8000

-

Features:

-

new

-

Product name:

-

pur hot melt glue laminating machine

-

Model No.:

-

HC-PUR-1800

-

Glue type:

-

Hot Melt PUR Glue

-

Way of glue:

-

Coating

-

Cylinder dryer specification:

-

DIA 1200/1500mm * Roll-width 1800 (Customizable)

-

Heating method:

-

Electrical Heating

-

Laminating speed:

-

0-35 M/min

-

Material Width:

-

1800mm (customizable)

-

Power of mold temperature controller:

-

18KW

-

OEM service:

-

YES

Quick Details

-

Voltage:

-

custom-made

-

Application:

-

garments

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HICKEY

-

Power:

-

55kw

-

Weight:

-

8000

-

Features:

-

new

-

Product name:

-

pur hot melt glue laminating machine

-

Model No.:

-

HC-PUR-1800

-

Glue type:

-

Hot Melt PUR Glue

-

Way of glue:

-

Coating

-

Cylinder dryer specification:

-

DIA 1200/1500mm * Roll-width 1800 (Customizable)

-

Heating method:

-

Electrical Heating

-

Laminating speed:

-

0-35 M/min

-

Material Width:

-

1800mm (customizable)

-

Power of mold temperature controller:

-

18KW

-

OEM service:

-

YES

Product Description

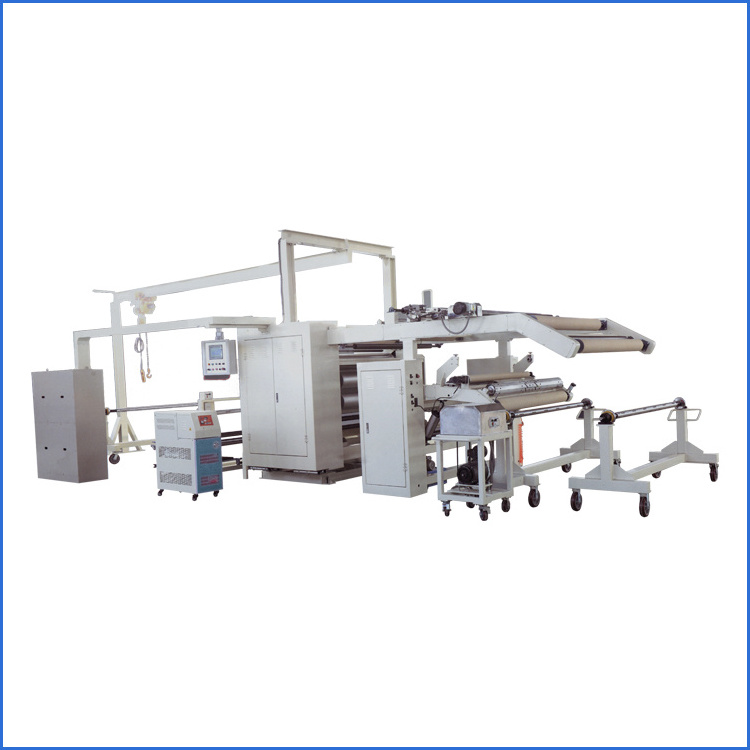

HC-PUR-1800

Hot Sale Fabric Film PUR Hot Melt Glue Laminating Machine For Protection Suit

|

● This machine adopts

PLC

and touch screen control, which is convenient and fast.

|

|

|

|

|

||||

|

● This machine is equipped with a

tension-free discharge device

and a heat-conducting oil heating circulation system to precisely control the temperature of the glue application and the blade.

|

|

|

|

|

||||

|

● This machine adopts the

rubberized plate

to melt and glue, and the amount of glue is precisely and controllable. Customers can choose the trimming device according to their needs.

|

|

|

|

|

||||

|

● After the finished product is laminated, the large package is used for winding.

|

|

|

|

|

||||

|

Product Parameter

|

|

|

|

Model No.

|

HC-PUR-1800

|

|

|

Glue type

|

PUR hot melt glue

|

|

|

Way of glue

|

coating

|

|

|

Cylinder dryer specification

|

DIA 1200/1500mm * Roll-width 1800 (can be defined by customers)

|

|

|

Heating method

|

Electrical Heating

|

|

|

Laminating speed

|

0-35 M/min

|

|

|

Power of mold temperature controller

|

18KW

|

|

|

Machine total power

|

60KW

|

|

|

Voltage

|

Three phase 380V 50Hz (customizable)

|

|

|

Material Width

|

1800mm (customizable)

|

|

|

Overall dimension

|

9600×3200×3200mm

|

|

|

Weight

|

6500KG

|

|

Detailed Images

|

Features and Advantages

|

|

|

|

|

||||

|

● The finished product has no residual solvent and production pollution-free emissions.

|

|

|

|

|

||||

|

● PUR hot melt adhesive wet solid reaction, irreversible, strong adhesion, washable, good fastness.

|

|

|

|

|

||||

|

● PUR hot melt adhesive does not contain water and solvent, no need to dry, laminating speed is fast.

|

|

|

|

|

||||

|

● PUR has excellent matte performance, low precipitation and neutral color characteristics, and can be applied to medical products that require repeated disinfection.

|

|

|

|

|

||||

|

● The laminating product has the characteristics of environmental protection, non-toxicity, good laminating fastness, soft hand feeling, high temperature resistance, moisture resistance, long-lasting elasticity, abrasion resistance, oil resistance and anti-aging.

|

|

|

|

|

||||

|

● High-precision coating roller, ultra-low coating amount, saving production costs.

|

|

|

|

|

||||

|

● The laminating process is fully linked and controlled, the substrate is not stretched, the quality is light and soft, and the hand feel is good.

|

|

|

|

|

||||

|

● Heating adopts mold temperature machine, heating is fast, heat is even, energy saving.

|

|

|

|

|

||||

|

● The melt glue system is independent, and the melt glue is fully fast.

|

|

|

|

|

||||

|

● Point-like or mesh-like sizing, the finished product has good air permeability and strong stereoscopic effect.

|

|

|

|

|

||||

|

● The whole machine adopts PLC and touch screen control, with high degree of automation and convenient operation.

|

|

|

|

|

||||

Aluminum opening roller

Aluminum opening roller

Electrical control device

Safety chuck

Mold temperature controller

Coating device

Buffer shaft

Heating mantle

Sliding platform for rectifying deviation

Deviation correction hydraulic pump

Winder

Rewinding power cabinet

|

Hot-sale products

|

Process and Certifications

Chamber of Commerce Certificate

High-tech enterprise certification

Technological Innovation Award

Application

This PUR hot melt glue laminating machine can be applied to a variety of materials, such as cloth to cloth, cloth to film, sponge to leather, sponge to non-woven fabric and other materials.

|

Industry

|

Laminating material

|

|

Textiles & Cloth Industry

|

Fabric to fabric: textiles, jersey, fleece, Nylon, etc.

|

|

Health & Medical Products Industry

|

Fabric to Sponge/ Foam

|

|

Bags Industry

|

Fabric to Leather/Artificial Leather,etc.

|

|

Packaging Industry

|

Fabric to Nonwoven

|

|

Footwear Industry

|

Fabric to films, such as PU film, TPU film, PE film, PVC film,etc.

|

|

Car cushion industry

|

EVA to PVC

|

Company Introduction

Yancheng Hickey Machinery Co., Ltd is is a professional manufacture of all kinds of laminating machines, rapid thermal shaping machine, and footwear machines, located in Yancheng, Jiangsu province, China. We have manufacturing experience of laminating machines for more than 20 years.

International Cooperation

Hickey adhere to take the road of the development of science and technology innovation.We enjoy good sale in over 20 countries and regions. We have close technical cooperation and trade relations with Italy, Germany, Turkey, USA and other countries and regions.

Packing&Shipping

|

Inner Package: Protective Film, etc

|

|

Outside Package: Standard Export Container

|

FAQ

|

1. Q:Are you a trading company or a manufacturer ?

|

|

|

|

|

||||

|

A: We are a manufacturer.

|

|

|

|

|

||||

|

2. Q:Where is your factory ?

|

|

|

|

|

||||

|

A: Our factory is located in Yancheng, Jiangsu, China, about 4 hours from Shanghai. All clients are most welcomed to visit us.

|

|

|

|

|

||||

|

3. Q: What is your MOQ of this item?

|

|

|

|

|

||||

|

A: 1 set per style.

|

|

|

|

|

||||

|

4. Q:How about the lead time ?

|

|

|

|

|

||||

|

A: It depends on your order quantity. Normal size laminating machine costs 20 days.

|

|

|

|

|

||||

|

5. Q: How do you guarantee the quality?

|

|

|

|

|

||||

|

A: We have certificate of patent and professional QCs.

|

|

|

|

|

||||

Hot Searches