- Product Details

- {{item.text}}

Quick Details

-

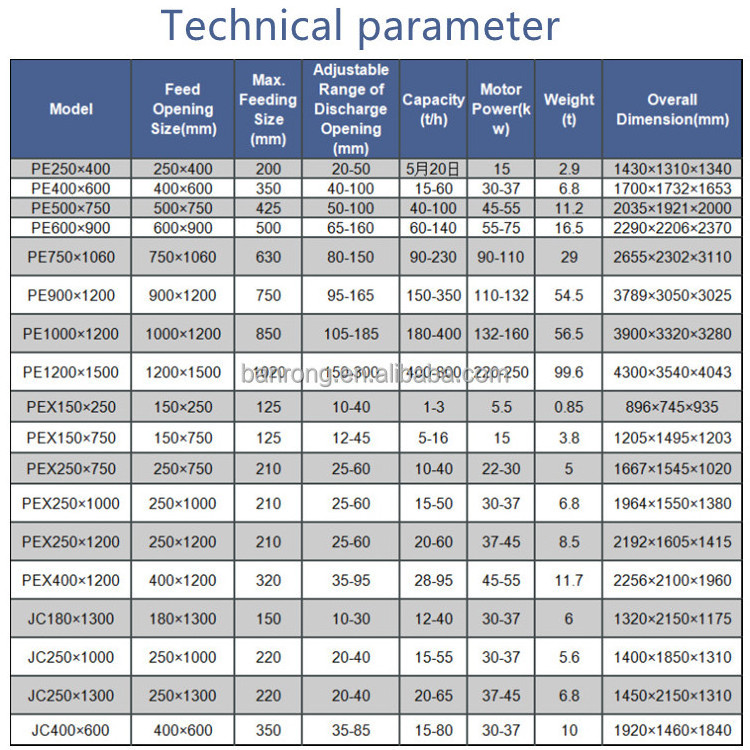

Dimension(L*W*H):

-

reference the technical parameters

-

Weight:

-

2800 KG

-

Machine Type:

-

Jaw Crusher

-

After Warranty Service:

-

Lifelong Service

-

After-sales Service Provided:

-

Lifelong Service

-

Color:

-

Customer's Request

-

Keyword:

-

Crusher, Stone Crusher

-

Max Feeding Size:

-

425mm

-

Size of Output:

-

50-120mm

-

Wearing parts:

-

Jaw Plate,Toggle Plate

-

Spare parts supply:

-

Lifelong Provide

Quick Details

-

Application:

-

construsction,, limest,cobble stoneone

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BANRONG

-

Dimension(L*W*H):

-

reference the technical parameters

-

Weight:

-

2800 KG

-

Machine Type:

-

Jaw Crusher

-

After Warranty Service:

-

Lifelong Service

-

After-sales Service Provided:

-

Lifelong Service

-

Color:

-

Customer's Request

-

Keyword:

-

Crusher, Stone Crusher

-

Max Feeding Size:

-

425mm

-

Size of Output:

-

50-120mm

-

Wearing parts:

-

Jaw Plate,Toggle Plate

-

Spare parts supply:

-

Lifelong Provide

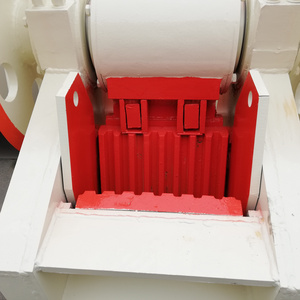

Jaw crusher is used in the first working procedure of rock crushing in all kinds of mines. All kinds of ores whose compressive strength is not higher than 320MPa can be processed to medium granularity at one time. They often form a complete sand and stone production line together with cone crusher, counter crusher, sand making machine, etc. It is widely used in mining, metallurgy, chemical industry, building materials, electric power, water conservancy, transportation and other fields. The jaw crusher is mainly composed of frame, eccentric shaft, big belt pulley, flywheel, side guard, elbow back seat, gap adjusting screw, reset spring, fixed jaw plate and movable jaw plate.

1. Large crushing ratio and even discharged materials.

2. Large and reliable adjusting range of discharged outlet meets various requirements.

3. Safe and reliable lubrication system,easily changed spare parts and easy maintenance.

4. Simple structure and low operation cost.

5. Low noise and little dust pollution.

The belt and belt pulley are driven by a motor, and the movable jaw moves up and down via eccentric shaft. The angle between fixed jaw and movable jaw becomes smaller when the moving jaw runs down, then the materials are crushed into pieces. It becomes bigger when the movable jaw runs up. The movable jaw plate leaves the fixed jaw plate under the action of tension rod and spring, then the end products come out from the crushing cavity.

The belt and belt pulley are driven by a motor, and the movable jaw moves up and down via eccentric shaft. The angle between fixed jaw and movable jaw becomes smaller when the moving jaw runs down, then the materials are crushed into pieces. It becomes bigger when the movable jaw runs up. The movable jaw plate leaves the fixed jaw plate under the action of tension rod and spring, then the end products come out from the crushing cavity.

T he machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below: Nude packing. Bundle packing. Grass rope packing. Water proof packing. Wooden pallets packin g. Wooden box or carton box packing.