- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2024

-

Models:

-

DP500DV

-

Z Axis loas:

-

6kg

-

Y Axis load:

-

15kg

-

XY max. movement speed:

-

0-1000mm/s

-

Z max. movement speed:

-

0-500mm/s

-

Repeatability:

-

±0.01mm/axis

-

Setting method:

-

17 inch monitor+keyboard and mouse combination

-

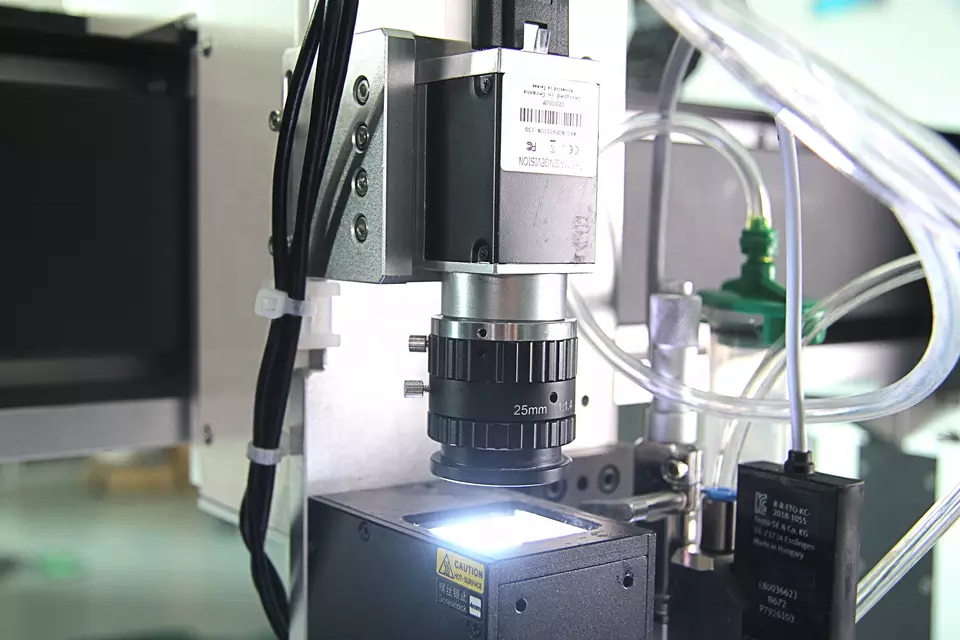

Camera:

-

1.3MP/5MP optional

-

Min. diameter for glue spraying:

-

0.2mm(depending on glue specification)

-

Key words:

-

glue dispensing machine

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Green

-

Weight (KG):

-

220

-

Marketing Type:

-

New Product 2024

-

Models:

-

DP500DV

-

Z Axis loas:

-

6kg

-

Y Axis load:

-

15kg

-

XY max. movement speed:

-

0-1000mm/s

-

Z max. movement speed:

-

0-500mm/s

-

Repeatability:

-

±0.01mm/axis

-

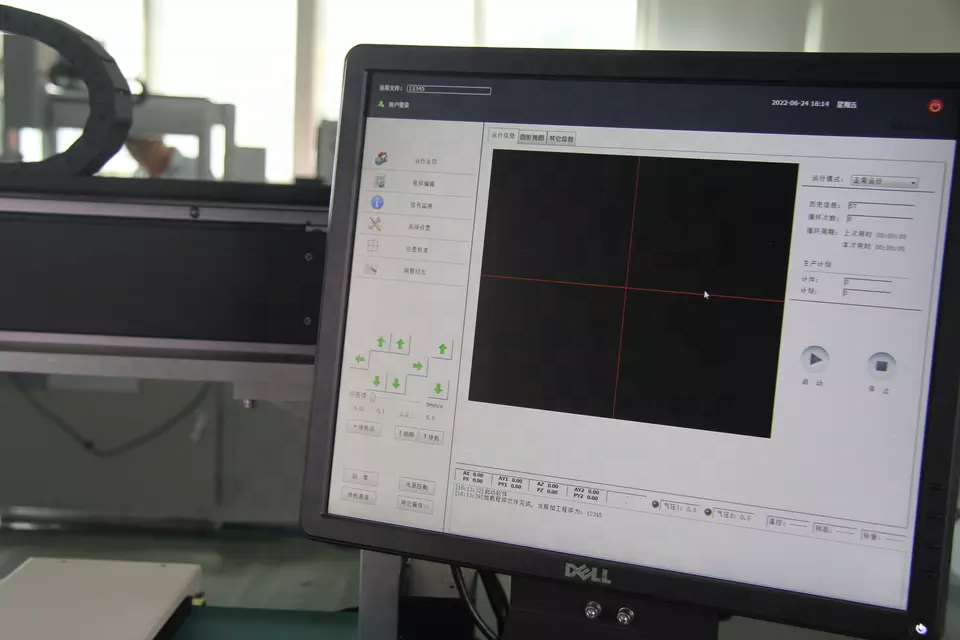

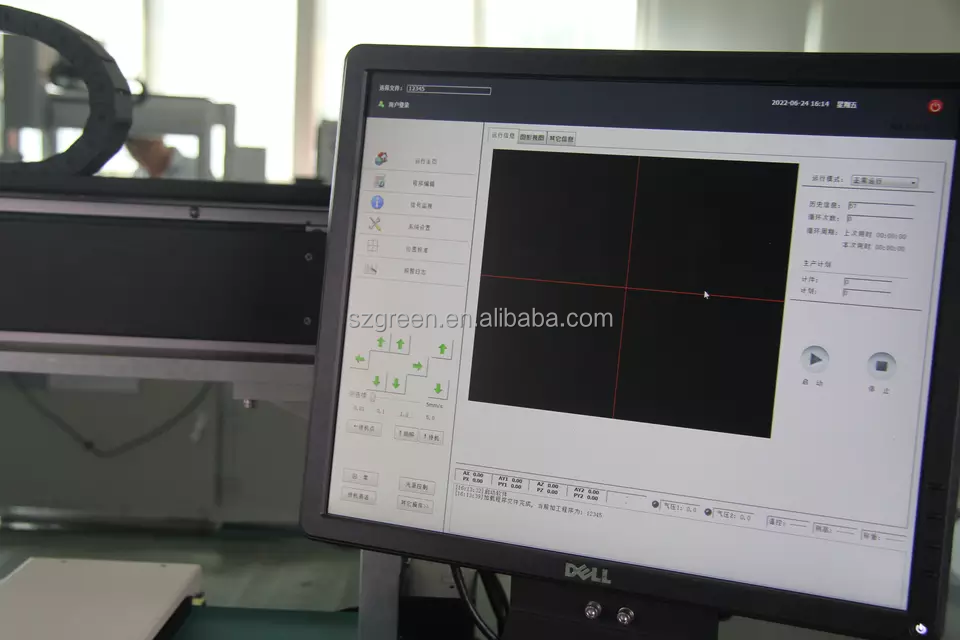

Setting method:

-

17 inch monitor+keyboard and mouse combination

-

Camera:

-

1.3MP/5MP optional

-

Min. diameter for glue spraying:

-

0.2mm(depending on glue specification)

-

Key words:

-

glue dispensing machine

Product Description

Welcome global distributors/agents to join us!

email: sales06@greensoldering.com Tel&wechat:+86-13510965373

Syringe dispensing

Min. point diameter: 0.2mm;

Min.line diameter: 0.3mm

(depending on glue specification);

Camera:1.3MP/5MP(for optional)

Program method: 17 inch monitor+keyboard and mouse combination

Syringe dispensing press controller

Input air pressure:0.4-0.7Mpa;

Dispensing mode: piezo valve/pneumatic valve/screw valve,etc.

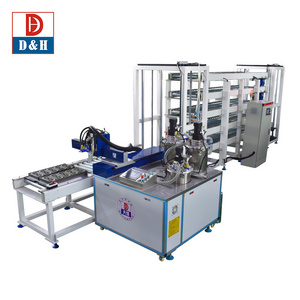

Green High-Speed Dispenser Machine DP500DV Advantages:

1. Support point, line, surface, arc, circle, irregular curve and other locus graph dispensing functions;

2. The size and thickness of glue volume, glue dispensing speed, glue dispensing time and glue stop time can all be set by parameters;

3. It can quickly dot, draw lines and draw circles on the product plane;

4. It has functions such as area array, translation and rotation operations;

5. Support CCD visual positioning, including Maek correction, with straight line and arc edge grab functions, can be arrayed and multiple products can be individually photographed for identification and positioning;

6. Drive mode: servo motor + grinding screw drive;

7. Working method: piezoelectric valve/pneumatic valve, screw valve, etc.;

8. The equipment is controlled by servo motor and grinding screw, which ensures high-speed movement, high precision and high consistency;

9. Modular structure design, easy to maintain and maintain.

Specification

|

Item

|

Specification

|

|

Product name

|

Industrial automatic high-speed dispensing robot machine

|

|

Model

|

DP500DV

|

|

Working range

|

DP500DV(500*300*300*100);DP600DV(600*400*400*100);

DP300V(300*300*100) ; DP400V(400*400*100);DP500V(500*500*100);

|

|

Z Axis load

|

6kg

|

|

XY aixs loas

|

15kg

|

|

XY axis movement speed(Max.)

|

1-1000mm/s

|

|

Z axis movement speed(Max.)

|

0-500mm/s

|

|

Repeatability

|

±0.01mm/axis

|

|

Setting method

|

17 inch monitor+keyboard and mouse combination

|

|

Min. diameter for spraying

|

0.2mm(depending on different glue specifications)

|

|

Min. line diameter

|

0.3mm(depending on different glue specifications)

|

|

Camera

|

1.3MPa (5MPa for optional)

|

|

Drive mode

|

Servo motor+grinding screw+precision guide rail

|

|

Max. power

|

350W

|

|

Input air pressure

|

0.4-0.7Mpa

|

|

Keywords

|

automated glue dispensing machine

|

Principle of dispensing machine

Dispensing machine, also known as glue filling machine and glue filling machine,

is an automatic equipment that controls the fluid and drips, coats and seals the liquid on the product surface or inside the product.

Dispenser is mainly used in electronics, machinery, LCD and other industries

. It can not only

save labor costs,

but also

achieve automation and accuracy, effectively improving product quality.

1.

Principle:

The dispensing machine

sends compressed air into the rubber bottle (syringe) to press the rubber into the feed tube connected to the piston chamber. When the piston is on the up stroke, the piston chamber is filled with rubber. When the piston pushes the rubber dripping needle downward, the rubber is pressed out of the needle nozzle. The amount of glue dripped is determined by the downward stroke distance of the piston, which can be adjusted manually or controlled in software.

2. Features: High speed, low sensitivity to glue viscosity.

3. Advantages: It can improve dispensing speed, dispensing environment and dispensing quality.

|

GR-5551D(UV glue dispensing machine)

|

DP300RR(Glue spray machine)

|

DP500D (Hot melt glue dispenser)

|

|

DP500DV high speed glue dispenser

|

DP500D benchtop glue dispenser

|

LAW300V Laser solder paste dispenser

|

Dispenser can be divided into two working modes: 1. Manual dispensing: dispense glue on electronic products manually using the principle of manual dispensing machine. This process is simple and low in cost. The disadvantage is that dispensing efficiency is slow, which will consume a lot of labor.

2. Automatic dispensing: The principle of the LCD dispensing machine is to use air pressure to push the glue out within the set time. The instrument controls the time of each infusion to ensure that the amount of

each infusion is the same. As long as the air pressure, time and proper needle nozzle are adjusted, the amount of each infusion can be easily changed, convenient and accurate. Dispensing machine has high speed and low sensitivity to glue viscosity, which can speed up dispensing, improve dispensing environment, and improve dispensing quality. It is an indispensable production equipment in many industries.

each infusion is the same. As long as the air pressure, time and proper needle nozzle are adjusted, the amount of each infusion can be easily changed, convenient and accurate. Dispensing machine has high speed and low sensitivity to glue viscosity, which can speed up dispensing, improve dispensing environment, and improve dispensing quality. It is an indispensable production equipment in many industries.

Green Benchtop Glue Dispensing Machine

Widely used for products:

Mobile phone buttons, printing, switches, connectors, computers, digital products,digital cameras,camera module(Lens fixed, VCM dispensing,etc.), MP3, MP4,electronic toys, speakers, buzzers, electronic components, integrated circuits, circuit boards, LCD screens, Relays, crystal components, LED lights,chassis bonding, optical lenses, mechanical parts sealing,etc..

Applicable glue:

Silica gel, EMI conductive glue, UV glue, AB glue, quick-drying glue, epoxy glue, sealant, hot glue, grease, silver glue, red glue, solder paste, thermal paste, solder resist paste,, transparent lacquer, screw fixing agent,etc..

Silica gel, EMI conductive glue, UV glue, AB glue, quick-drying glue, epoxy glue, sealant, hot glue, grease, silver glue, red glue, solder paste, thermal paste, solder resist paste,, transparent lacquer, screw fixing agent,etc..

Packing & Delivery

Hot Searches